Brewing type prepared dry rice noodles and preparation method thereof

A technology of dry rice noodles and brewing, which is applied in the field of brewing prepared dry rice noodles and its preparation, which can solve the problems of restricting long-distance circulation, large cooking losses, and difficulty satisfying people.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

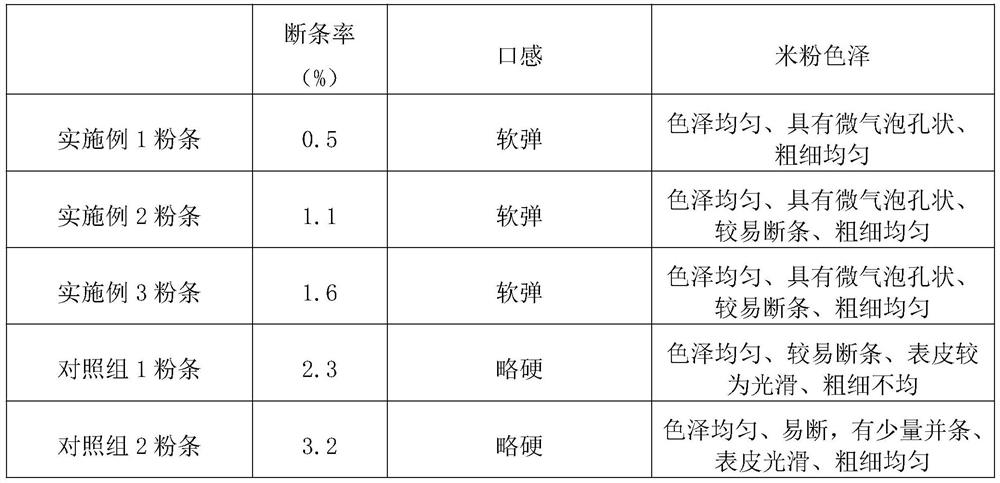

Examples

Embodiment 1

[0027] A preparation method for brewing dry rice noodles, comprising the following steps:

[0028] (1) Preparation of raw materials: take the following raw materials in parts by weight: 70 parts of rice, 30 parts of modified tapioca starch; wherein rice is selected from fresh early-canned rice and late-canned rice, and the weight ratio of early-canned rice and late-canned rice is 1:1; Modified tapioca starch is prepared according to the following steps: Dissolve sodium tripolyphosphate in water, the amount of water added is 30% of the weight of tapioca starch, then add tapioca starch and mix evenly, react under high temperature at 110°C, and then cool, After water washing, dehydration and drying, the modified tapioca starch is obtained;

[0029] (2) Soaking: After cleaning the rice, add water to soak for 8 hours, subject to the soaking of the rice;

[0030] (3) milling: the soaked rice in step (2) is filtered out, milled to obtain wet rice flour for subsequent use; the moistu...

Embodiment 2

[0036] A preparation method for brewing dry rice noodles, comprising the following steps:

[0037] (1) Preparation of raw materials: Take the following raw materials in parts by weight: 50 parts of rice, 20 parts of modified tapioca starch; wherein the rice is fresh Zaocan rice; modified tapioca starch is prepared according to the following steps: take sodium tripolyphosphate and add water Dissolving, the amount of water added is 25% of the weight of tapioca starch, then adding tapioca starch and mixing evenly, reacting at a high temperature at 100°C, then cooling, washing with water, dehydrating and drying to obtain the modified tapioca starch;

[0038] (2) Soaking: After cleaning the rice, soak it in water for 5 hours, subject to the softness of the rice;

[0039] (3) milling: the soaked rice in step (2) is filtered out, milled to prepare wet rice flour for subsequent use; the moisture of the wet rice flour is 30%, and the fineness is 80 orders;

[0040] (4) Allotment: Add ...

Embodiment 3

[0045] A preparation method for brewing dry rice noodles, comprising the following steps:

[0046] (1) Preparation of raw materials: Take the following raw materials in parts by weight: 80 parts of rice, 50 parts of modified tapioca starch; wherein rice is late-colored rice; modified tapioca starch is prepared according to the following steps: take sodium tripolyphosphate and dissolve in water , the amount of water added is 35% of the weight of the tapioca starch, then the tapioca starch is added and mixed uniformly, reacted at a high temperature at 120°C, and then cooled, washed with water, dehydrated and dried to obtain the modified tapioca starch;

[0047] (2) Soaking: Wash the rice and soak it in water for 12 hours, subject to the rice soaking until soft;

[0048] (3) milling: the rice soaked in step (2) is filtered out, milled to prepare wet rice flour for subsequent use; the moisture of the wet rice flour is 40%, and the fineness is 100 orders;

[0049] (4) deployment: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com