Device and method for measuring pH of electrode solution interface

A technology for measuring electrodes and solutions. It is applied in the fields of measuring devices, electrochemical variables of materials, and material analysis by electromagnetic means. It can solve the problems of large size, special requirements for the shape of the measured metal electrode, and the lack of repeatability of experiments. To achieve the effect of simple composition, accurate measurement of pH value, and real-time monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

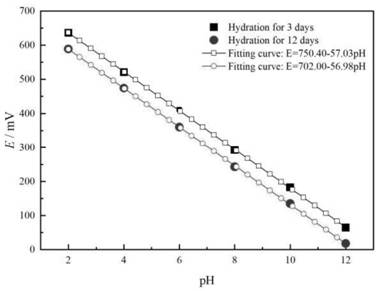

[0041] The device for measuring the pH of the electrode solution interface is as Figures 1A-1E As shown, it includes electrolytic cell chamber A8, electrolytic cell chamber B12, glass salt bridge 6, saturated calomel electrode 7, proton exchange membrane 9, platinum wire 11, IrOx microelectrode 28 and insulating hollow screw 29, wherein the electrolytic cell chamber The two ends of the chamber A8 are respectively provided with a clamp A5 and a clamp B13, and the two ends of the electrolytic cell chamber A8 are respectively in sealing contact with the clamp A5 and the clamp B13; the two ends of the electrolytic cell chamber B12 are respectively provided with a clamp C14 and a clamp B13. Fixture D30, the two ends of the electrolytic cell chamber B12 are in sealing contact with the fixture C14 and the fixture D30 respectively, and the fixtures A5, B13, C14 and D30 are connected and fixed by a fixing device; the fixture A5, the fixture Both B13 and clamp C14 are provided with pas...

Embodiment 2

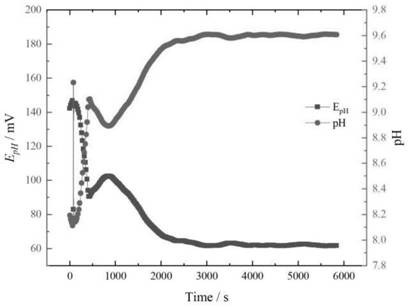

[0053] Adopt the method for above-mentioned device to measure metal electrode solution interface pH under the polarized condition, install by above-mentioned device, under the assistance of microscope, control metal electrode 3 surface and IrO by rotating insulating hollow screw rod 29 x The distance between the tips of the microelectrodes 28 is about 300 μm, and they are kept fixed. The medium solution to be measured is injected into the electrolytic cell chamber 8 and the electrolytic cell chamber 12 respectively, and the saturated calomel electrode 7 is used as a reference electrode, and the IrO x The microelectrode 28 is the working electrode to form a potential measurement system. The platinum wire 11 is used as the auxiliary electrode, the saturated calomel electrode 7 is used as the reference electrode, and the metal electrode 3 is used as the working electrode to form a polarization system. Constant polarization potential of -0.9V, continuous recording of IrO by data lo...

Embodiment 3

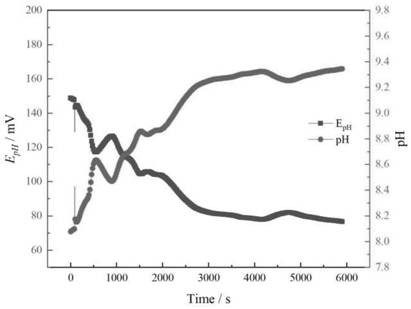

[0065] In this embodiment, the tested metal electrode material and the medium solution are the same as in Example 2, the difference is that the polarization potential applied to the tested metal electrode in this embodiment is -0.8V (vs. SCE), the test method and steps and implementation Example 2 is the same, the test results are as follows Figure 5 shown.

[0066] Depend on Figure 4 and Figure 5 It can be seen that the overall trend of the change of the pH value of the interface in the continuous test of nearly 100min is to rise rapidly first and then gradually reach a nearly steady state. The steady-state pH values are 9.6 and 9.3, respectively. It can be seen that the more negative the polarization potential, the higher the pH value of the solution near the interface of the metal electrode under test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com