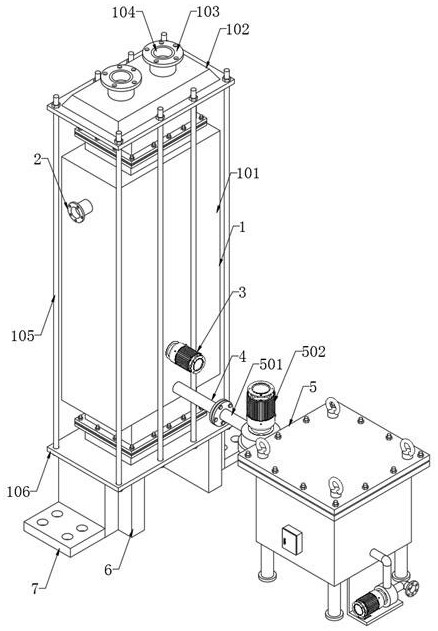

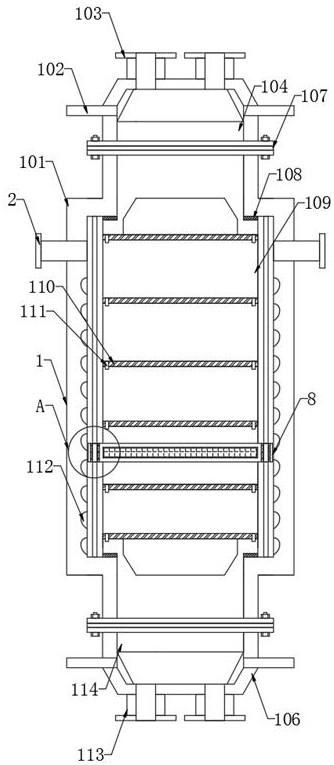

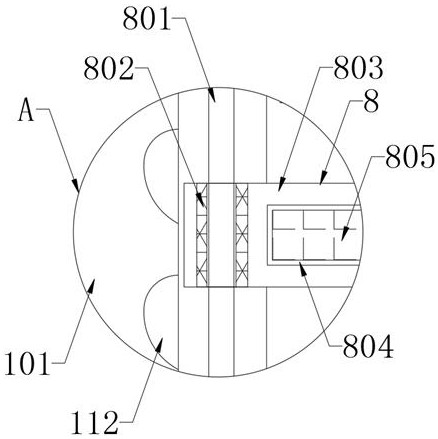

A rectangular block graphite heat exchanger for hydrochloric acid production

A technology of graphite heat exchanger and graphite heat exchange block, which is applied in the directions of regenerative heat exchangers, indirect heat exchangers, heat exchanger types, etc. Heat exchanger cleaning and other issues, to achieve the convenience of personnel operation, improve heat transfer performance, and avoid the effect of heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0039] As a specific embodiment of the present invention, the water purification mechanism 5 includes one end of the water guide pipe 501 in fixed communication with one end of the condensed water inlet 4, the other end of the water guide pipe 501 in fixed communication with the water outlet of the booster pump 502, and the booster pump 502 is fixedly installed on the top of the mounting plate 503, one side of the mounting plate 503 is fixedly connected to the middle part of one side of the purification box 504, and the water inlet end of the booster pump 502 is connected to the outlet on the top of the purification box 504 side through the water pipe. The water port is fixedly connected.

[0040] As a specific embodiment of the present invention, the water inlet of the bottom opening part on the other side of the purification box 504 is fixedly connected with the water outlet end of the water pump 509 through the water pipe, and the water pump 509 is fixedly installed on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com