Honeycomb-structure multilayer film on metal surface, and preparation method of honeycomb-structure multilayer film

A technology of honeycomb structure and metal surface, which is applied in the direction of metal material coating process, coating, vacuum evaporation plating, etc., can solve the problems of insufficient strength and toughness, and achieve the effect of improving shear strength and excellent geometric mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

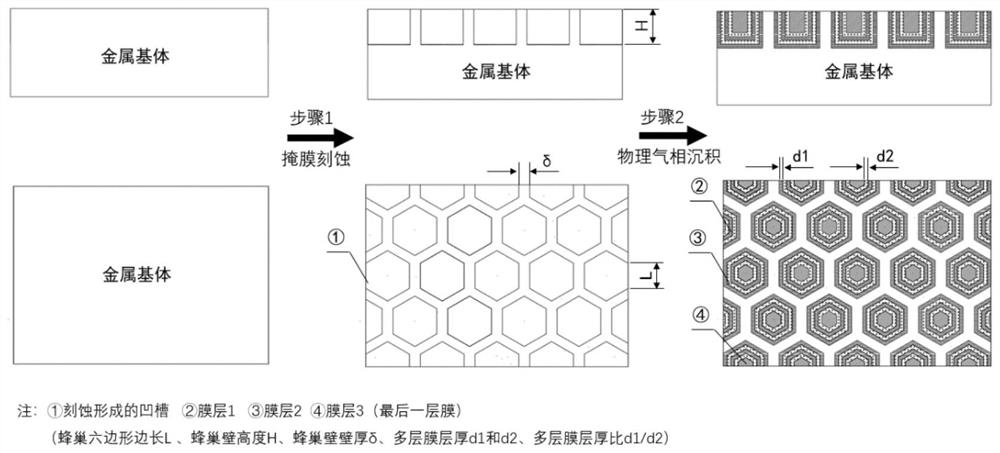

[0025] The present invention proposes a honeycomb configuration multilayer film on a metal surface, and its preparation method specifically includes the following steps:

[0026] Step 1: Pretreat the surface of the metal substrate that needs to be prepared with a multilayer film on the surface, and perform selective etching on the surface of the metal substrate to form a honeycomb structure skeleton on the surface of the metal substrate.

[0027] Step 1.1: Select the metal that needs to be prepared with a multi-layer film on the surface as the substrate, grind and polish the surface, and then clean it with acetone and alcohol in ultrasonic waves.

[0028] Preferably, the base material can be steel, titanium, aluminum, magnesium, tungsten, tantalum, niobium, molybdenum, chromium, and an alloy mainly composed of one of these elements.

[0029] Step 1.2: Make a mask plate with a projected pattern on the surface of the honeycomb wall structure. The side length L of the hexagon of...

Embodiment 1

[0033] This example prepares a honeycomb structure Ti / TiN multilayer film on the surface of low carbon steel Q235, including the following steps:

[0034] Step 1: Pretreat the surface of the low-carbon steel (Q235) plate, and perform selective etching on the surface of the low-carbon steel (Q235) plate to form a honeycomb structure skeleton on the surface of the low-carbon steel (Q235) substrate.

[0035] Step 1.1: Substrate cleaning. Prepare a low carbon steel (Q235) plate, grind and polish its surface with sandpaper, and then clean its surface with acetone and alcohol respectively.

[0036] Step 1.2: Make a mask plate with a projected pattern on the surface of the honeycomb wall structure. The side length L of the hexagon of the honeycomb is 1000 microns, and the wall thickness of the honeycomb is 200 microns.

[0037] Step 1.3: wet etching (hydrochloric acid solution) is used to etch a honeycomb structure on the surface of the low carbon steel Q235 substrate. The etch de...

Embodiment 2

[0041] This example prepares a honeycomb structure Ti / TiN multilayer film on the surface of a titanium alloy (Ti6Al4V), including the following steps:

[0042] Step 1: Pretreat the surface of the titanium alloy (Ti6Al4V) plate, and perform selective etching on the surface of the titanium alloy (Ti6Al4V) plate to form a honeycomb structure skeleton on the surface of the titanium alloy (Ti6Al4V) substrate.

[0043] Step 1.1: Substrate cleaning. Prepare a titanium alloy (Ti6Al4V) plate, grind and polish its surface with sandpaper, and then clean its surface with acetone and alcohol respectively.

[0044] Step 1.2: Make a mask plate with a projected pattern on the surface of the honeycomb wall structure. The side length L of the hexagon of the honeycomb is 10 microns, and the wall thickness of the honeycomb is 2 microns.

[0045] Step 1.3: Laser etching is used to prepare a honeycomb structure skeleton on the surface of the titanium alloy (Ti6Al4V) substrate. The etch depth is 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com