Water-based inorganic zinc silicate shop primer and preparation method thereof

A technology of inorganic zinc silicate and shop primer, which is applied in the direction of primer, alkali metal silicate paint, coating, etc., and can solve the problem of affecting stackability, which depends on the quick drying and crosslinking of water-based inorganic zinc silicate primer Curing degree and other issues to achieve the effect of improving the wettability of the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

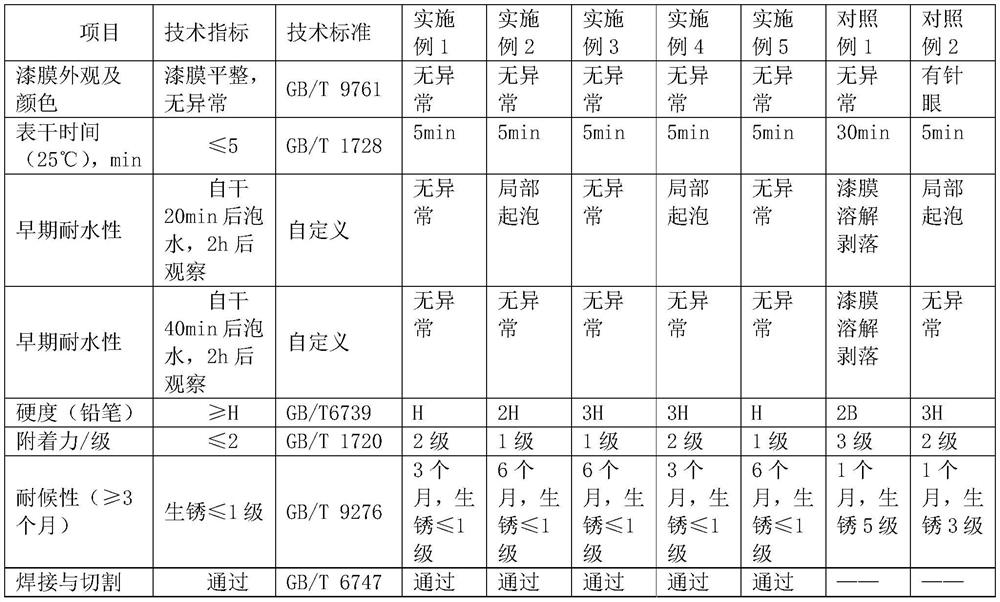

Examples

Embodiment 1

[0026] (1) Take 80g of low-modulus potassium silicate with a modulus of 3.7, add 44.5ml of water to make a potassium silicate solution, then slowly add 41.6g of silica sol AJN830 dropwise in about 30 minutes, heat to 55°C, and continue stirring until translucent colloidal fluid.

[0027] (2) After adding the silica sol dropwise, after the solution is clarified, add 3.8g of silane coupling agent KH550 dropwise in about 20 minutes, continue stirring and heat at 55°C for 1 hour to prepare high modulus potassium silicate.

[0028] (3) Take 40g of high modulus potassium silicate, add 1.7g of styrene-butadiene emulsion, 0.21g of anti-settling agent, and 0.07g of defoamer under stirring at 35°C, and keep stirring for 15 minutes to obtain an emulsion, which is the base material component .

[0029] (4) Take 80g of zinc powder, 30g of ferrophosphorus powder, and 5g of feldspar powder, and mix them uniformly in a ball mill to obtain powder, which is the curing agent component.

[0030...

Embodiment 2

[0033] (1) Take 82.1g of low-modulus potassium silicate with a modulus of 3.7, add 67.5ml of water to make potassium silicate solution, slowly add 43g of silica sol AJN1430 dropwise in about 30 minutes, heat to 55°C, and continue stirring until translucent gel body fluid.

[0034] (2) After adding the silica sol dropwise, after the solution is clarified, add 4g of silane coupling agent KH540 dropwise in about 20 minutes, keep stirring and heat at 55°C for 1 hour to prepare high modulus potassium silicate.

[0035] (3) Take 50g of high modulus potassium silicate, add 3.72g of styrene-butadiene emulsion, 1.01g of anti-settling agent, and 0.41g of defoamer under stirring at 35°C, and keep stirring for 15min to obtain the emulsion, which is the base material component .

[0036] (4) Take 75g of zinc powder, 30g of ferrophosphorus powder, and 30g of feldspar powder, and mix them uniformly in a ball mill to obtain powder, which is the curing agent component.

[0037] (5) Take 50 g...

Embodiment 3

[0040] (1) Take 80g of low-modulus potassium silicate with a modulus of 3.7, add 45ml of water to make a potassium silicate solution, then slowly add 36.4g of silica sol AJN1430 dropwise in about 30 minutes, heat to 55°C, and continue stirring until translucent gel body fluid.

[0041] (2) After adding the silica sol dropwise, after the solution is clarified, add 4 g of silane coupling agent KH540 dropwise in about 20 minutes, keep stirring and heat at 55°C for 1 hour to prepare high modulus potassium silicate.

[0042] (3) Take 40g of high modulus potassium silicate, add 1.82g of styrene-acrylic emulsion, 0.52g of anti-settling agent, and 0.13g of defoamer under stirring at 35°C, and keep stirring for 15min to obtain the emulsion, which is the base material component .

[0043] (4) Take 45g of zinc powder, 25g of ferrophosphorus powder, and 5g of feldspar powder, and mix them uniformly in a ball mill to obtain powder, which is the curing agent component.

[0044] (5) Take 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com