Composition for preparing fracturing thickening agent, fracturing thickening agent and preparation method of fracturing thickening agent

A technology of composition and thickening agent, which is applied in the direction of drilling composition, chemical instrument and method, etc., to achieve the effects of remarkable salt resistance and temperature resistance, less damage to cores, and good viscoelasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099] This embodiment provides a fracturing thickener, and the raw material formula of the fracturing thickener is shown in Table 1;

[0100] Table 1

[0101]

[0102] The preparation method of described fracturing thickening agent comprises the following steps:

[0103] (1) Add 150 parts of white oil (industrial grade), 9 parts of Span 80 and 4.2 parts of Tween 80 in parts by weight into a four-necked flask equipped with a constant speed stirrer, a nitrogen inlet, a thermometer and a reflux tube. Stir until uniform at 30°C and 400r / min to obtain the first oil phase system;

[0104] (2) 240 parts of acrylamide, 1.5 parts of 2-acrylamide-2-methylpropanesulfonic acid, 0.9 parts of n-butyl methanesulfonate, 1.2 parts of propenyl octadecyl dimethyl ammonium chloride, 0.45 One part of N-(2-bromobenzene) cyclopropane carboxamide, 0.75 part of sodium 4-acryloylbenzenesulfonate and 178 parts of deionized water were made into a solution, the pH value was adjusted to 6~7, and the ...

Embodiment 2

[0110] This embodiment provides a fracturing thickener, and the raw material formula of the fracturing thickener is shown in Table 2;

[0111]

[0112]

[0113] The preparation method of described fracturing thickening agent comprises the following steps:

[0114] (1) Add 150 parts of white oil (industrial grade), 9 parts of Span 80 and 4.2 parts of Tween 80 in parts by weight into a four-necked flask equipped with a constant speed stirrer, a nitrogen inlet, a thermometer and a reflux tube. Stir until uniform at 30°C and 400r / min to obtain the first oil phase system;

[0115] (2) 240 parts of acrylamide, 1.7 parts of 2-acrylamide-2-methylpropanesulfonic acid, 1.1 parts of n-butyl methanesulfonate, 1.2 parts of propenyl octadecyl dimethyl ammonium chloride, 0.45 Part of N-(2-bromobenzene)cyclopropanecarboxamide, 0.75 part of sodium 4-acryloylbenzenesulfonate and 177.5 parts of deionized water were made into a solution, the pH value was adjusted to 6~7, and the solution w...

Embodiment 3

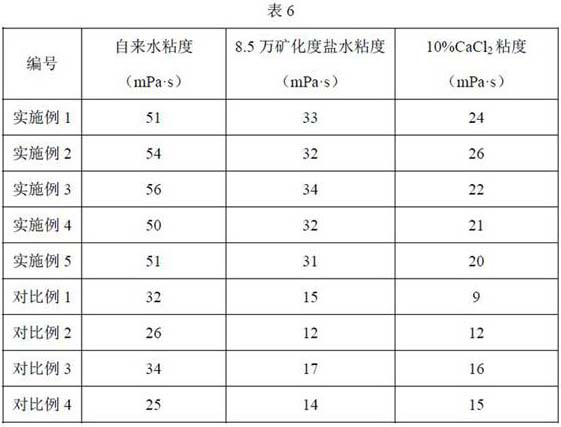

[0121] This embodiment provides a fracturing thickener, and the raw material formula of the fracturing thickener is shown in Table 3;

[0122]

[0123] The preparation method of described fracturing thickening agent comprises the following steps:

[0124] (1) Add 150 parts of white oil (industrial grade), 10 parts of Span 80 and 6 parts of Tween 80 in parts by weight into a four-necked flask equipped with a constant speed stirrer, a nitrogen inlet, a thermometer and a reflux tube. Stir until uniform at 30°C and 400r / min to obtain the first oil phase system;

[0125] (2) 270 parts of acrylamide, 1.5 parts of 2-acrylamide-2-methylpropanesulfonic acid, 1 part of n-butyl methanesulfonate, 1.35 parts of propenyl octadecyl dimethyl ammonium chloride, 1.11 Parts of N-(2-bromobenzene)cyclopropanecarboxamide, 1.5 parts of sodium 4-acryloylbenzenesulfonate and 143 parts of deionized water were made into a solution, the pH value was adjusted to 6~7, and the solution was added dropwis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com