Calcium silicate/magnesium silicate biological-bone porous implant as well as preparation method and application thereof

A technology of magnesium silicate and calcium silicate, which is applied in the field of biomedical materials, can solve the problems of limited development, uncontrollable, and non-through hole size, and achieve the goals of promoting bone healing, improving mechanical strength, and good biocompatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

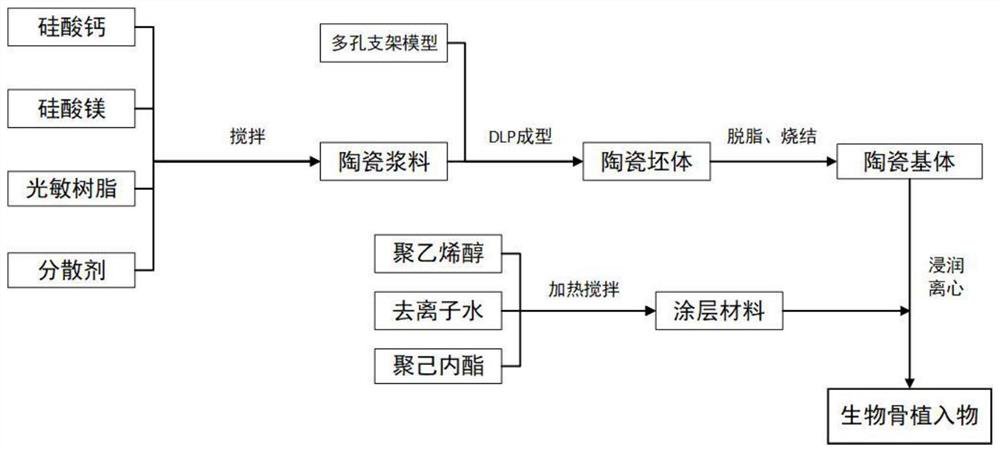

[0028] like figure 1 Shown, a kind of preparation method of calcium silicate / magnesium silicate biological bone porous implant comprises the following steps:

[0029] Step 1. Slurry preparation: Mix 80g of calcium silicate and 20g of magnesium silicate ceramic powder, add 70g of photosensitive resin and 4g of dispersant, add it to a vacuum mixer and work at a speed of 1200rpm for 20min to obtain a mixed ceramic slurry;

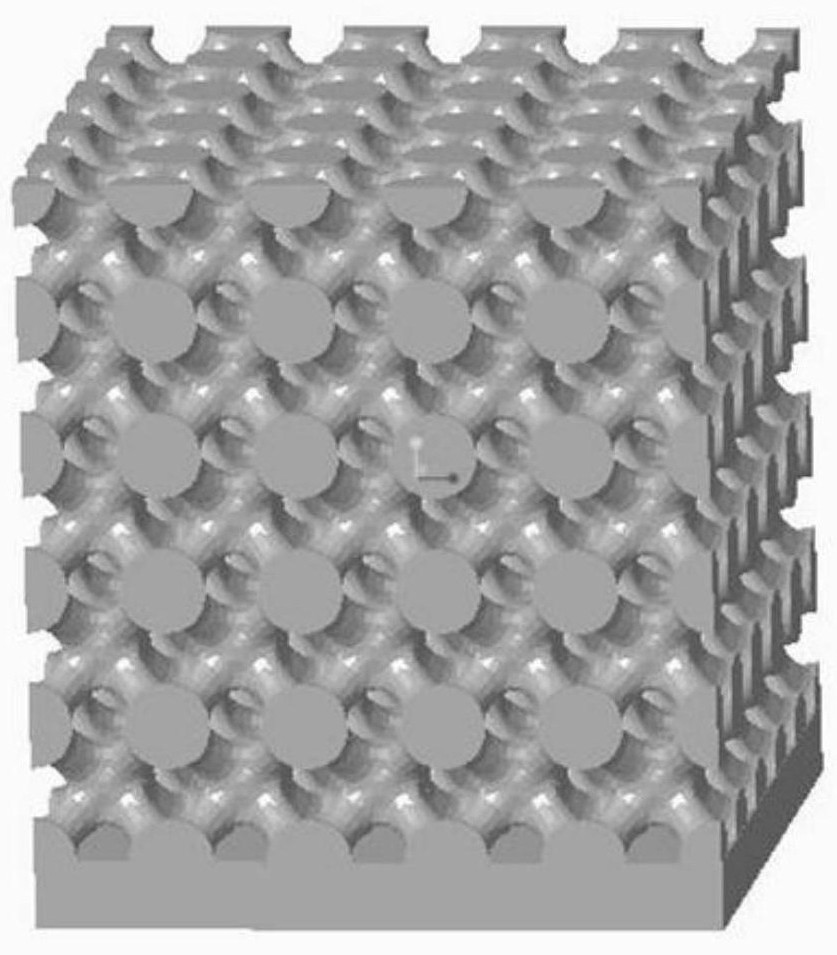

[0030] Step 2, green body preparation: use magics software to draw such as figure 2 The three-dimensional porous structure shown is saved in the format of .STL, and then the model is imported into the photocuring printer, the exposure time is set to 10 seconds, the printing layer thickness is 0.05mm, and then the slurry obtained in step 1 is added, and finally layer by layer Solidify to obtain a three-dimensional porous green body;

[0031] Step 3, degreasing and sintering: put the green body obtained in step 2 into a tubular degreasing furnace for degreasi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com