Surface treatment solvent for plastic electroplated part and treatment method

A technology of plastic electroplating and surface treatment, applied in jewelry and other directions, can solve the problems of interfering with the nano-spraying operation of plastic electroplating parts, affecting the quality of products, and dirtying the electroplating solution, so as to improve the mirror highlight effect, stabilize the solvent structure, and eliminate white spots. point effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

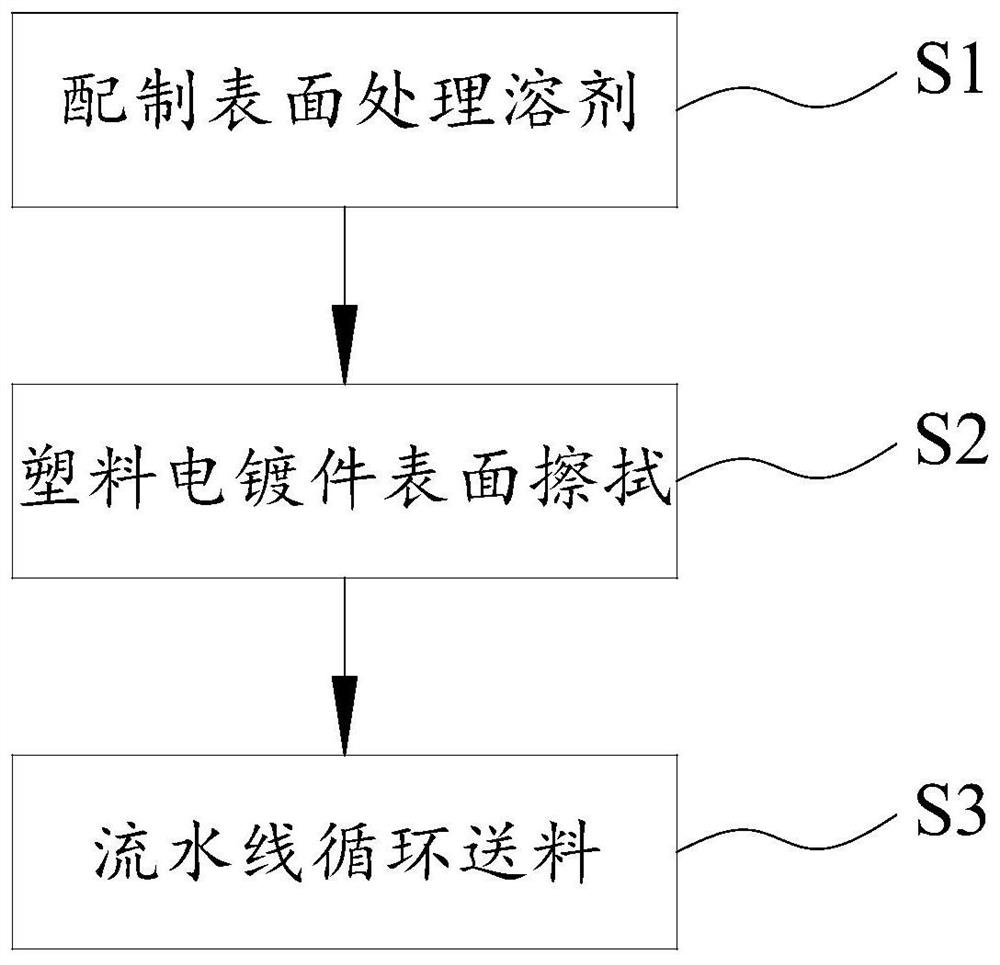

Method used

Image

Examples

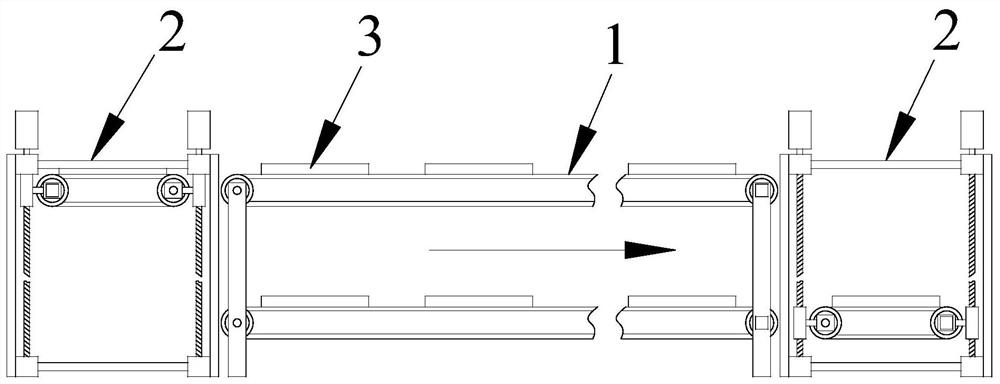

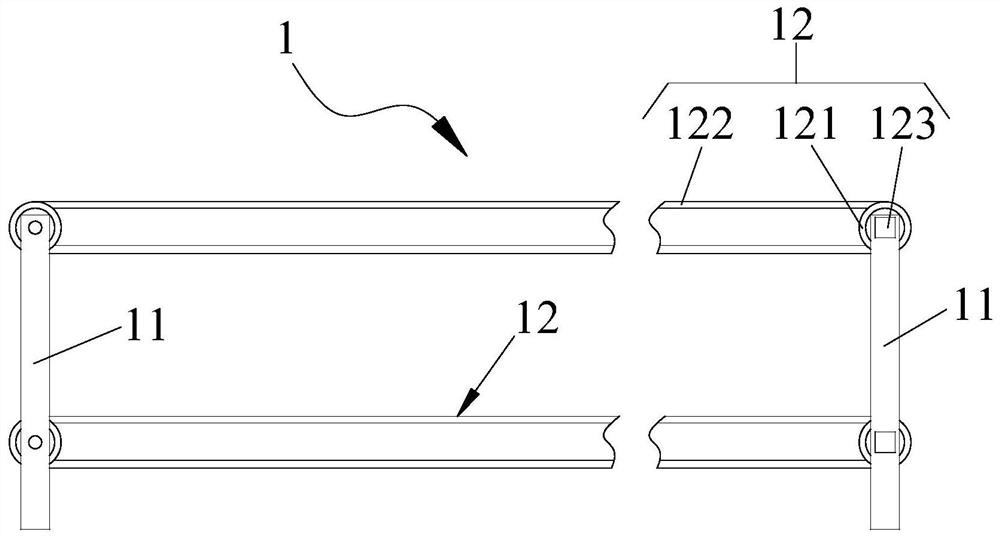

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0034] A solvent for the surface treatment of plastic electroplating parts comprises the following raw materials in mass percentage: 80% of anion surfactant, 2% of formaldehyde and 18% of deionized water.

[0035] Wherein, the anionic surfactant is sodium lauryl sulfate.

[0036] Using the above technical scheme, the solvent structure for the surface treatment of plastic electroplating parts is stable, has good solubility in water, and has good wetting and dispersing properties, which can well reduce white spots on the surface of plastic electroplating parts; the dodecane added in the components Sodium base sulfate has the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com