A high-throughput continuous casting and rolling aluminum-magnesium-manganese alloy plate for ships and its production process

An aluminum-magnesium-manganese alloy, continuous casting and rolling technology, applied in the field of aluminum alloy sheet processing, can solve the problems of looseness and shrinkage, easy to produce microstructure segregation, poor alloy fluidity, etc. The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

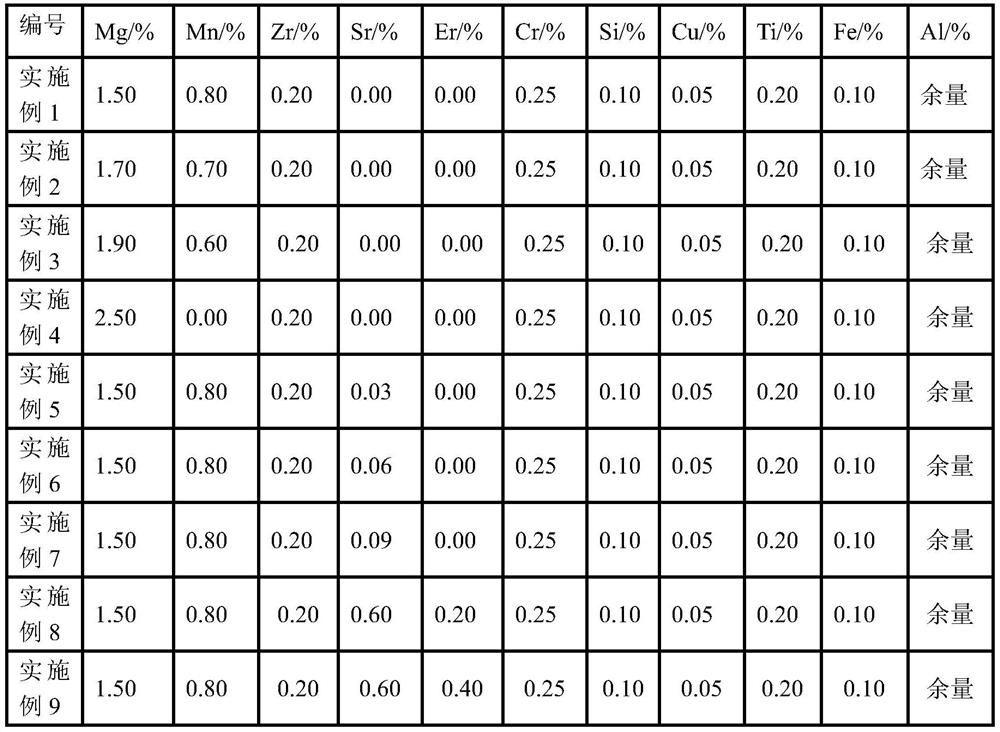

Embodiment 1

[0041] The invention provides a high-throughput continuous casting and rolling aluminum-magnesium-manganese alloy plate for ship air conditioner sheet metal parts. The chemical composition of the aluminum-magnesium-manganese alloy is calculated by mass percentage: Mg: 1.50%, Mn: 0.80%, Zr: 0.20 %, Cr: 0.25%, Sr: 0.00%, Er: 0.40%, Si: 0.10%, Cu: 0.05%, Ti: 0.02%, Fe: 0.10%, the balance is Al, and the product of this ratio is recorded as M1;

[0042] The production process of the high-throughput continuous casting and rolling aluminum-magnesium-manganese alloy sheet for ship air conditioner sheet metal parts mainly includes smelting and melt treatment process, continuous casting process, continuous rolling process and cold rolling process:

[0043] Step 1 Melting and Melt Treatment Process

[0044] (1) After cleaning the smelting furnace, add electrolytic aluminum liquid to the smelting furnace. The total weight of a furnace of molten aluminum is generally about 100t, of which t...

Embodiment 2

[0066] The invention provides a high-throughput continuous casting and rolling aluminum-magnesium-manganese alloy plate for ship air conditioner sheet metal parts. The chemical composition of the aluminum-magnesium-manganese alloy is calculated by mass percentage: Mg: 1.70%, Mn: 0.70%, Zr: 0.20 %, Sr: 0.00%, Er: 0.00%, Cr: 0.25%, Si: 0.10%, Cu: 0.05%, Ti: 0.02%, Fe: 0.10%, the balance is Al, and the product of this proportion is recorded as M2.

[0067] The preparation method of this embodiment is the same as that of Example 1.

Embodiment 3

[0069] The invention provides a high-throughput continuous casting and rolling aluminum-magnesium-manganese alloy plate for ship air conditioner sheet metal parts. The chemical composition of the aluminum-magnesium-manganese alloy is calculated by mass percentage: Mg: 1.90%, Mn: 0.60%, Zr: 0.20 %, Sr: 0.00%, Er: 0.00%, Cr: 0.25%, Si: 0.10%, Cu: 0.05%, Ti: 0.02%, Fe: 0.10%, the balance is Al, and the product of this proportion is recorded as M3.

[0070] The preparation method of this embodiment is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com