Eu(II) ion-doped single-phase full-spectrum-emission fluorescent powder as well as preparation method and application thereof

An ion doping and phosphor technology, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve the problems of high pollution and poor reduction effect, and achieve high safety, high color rendering index and luminous efficiency. , the effect of pollution-free reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

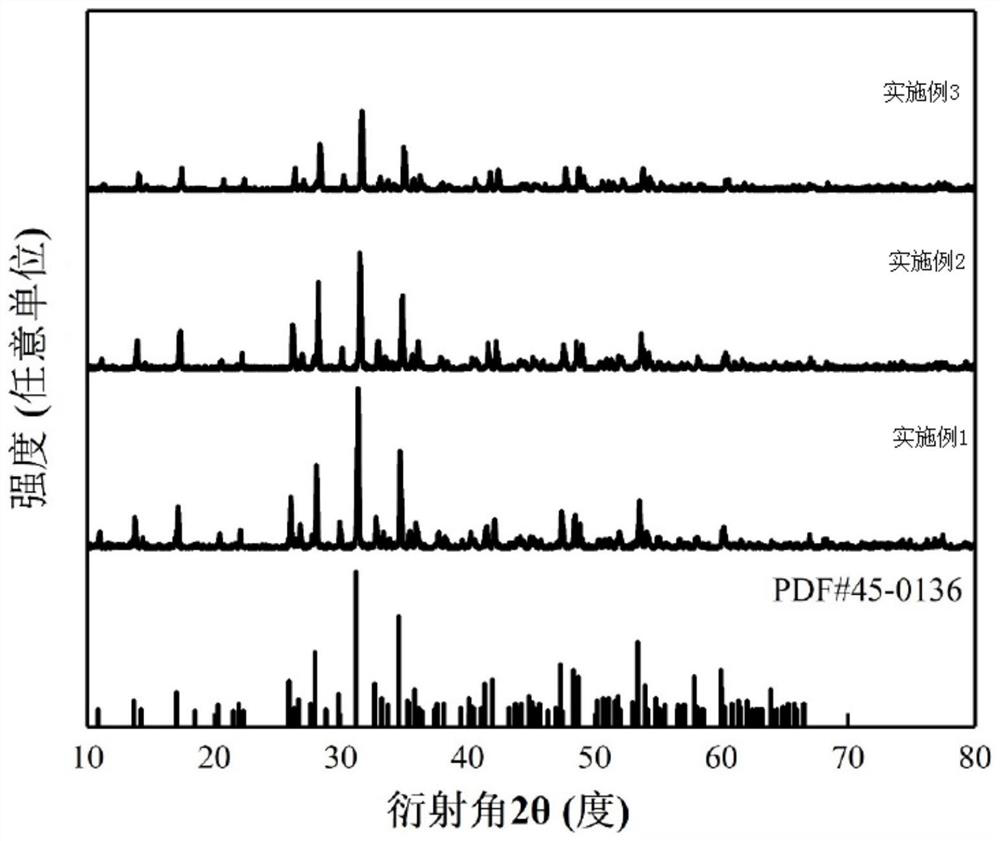

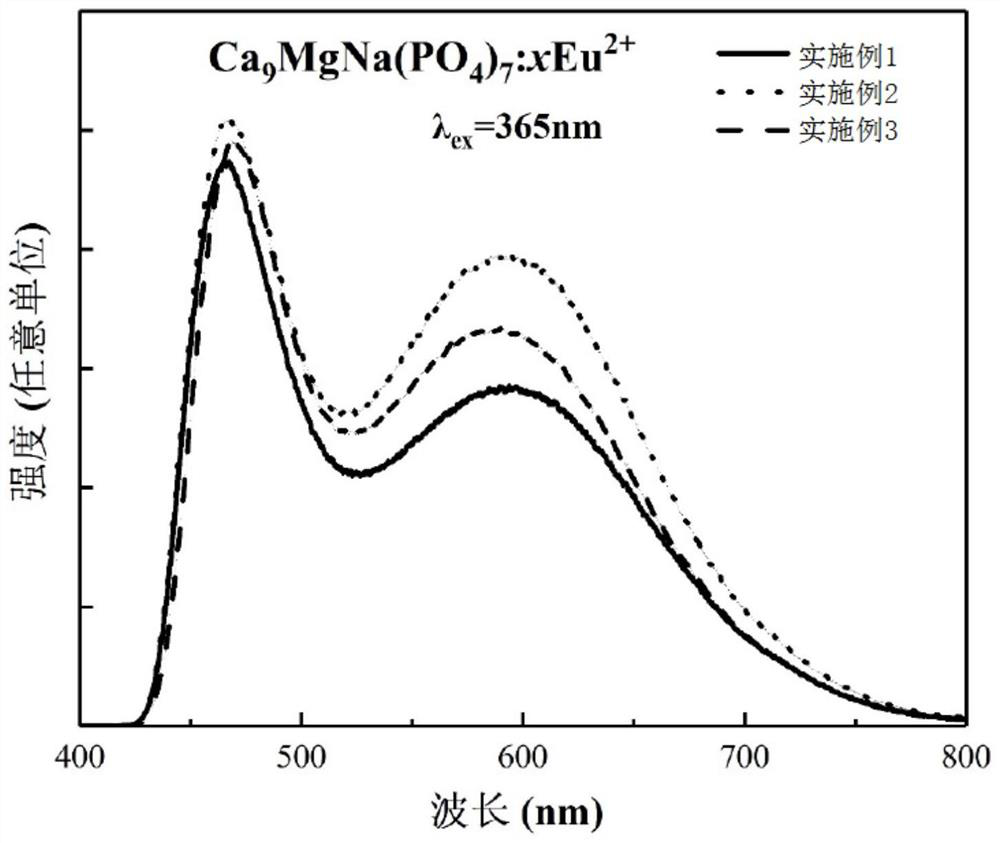

[0027] a kind of Eu 2+ A preparation method for ion-doped single-phase full-spectrum emission phosphor, comprising the following steps:

[0028] (1) According to Eu 2+ The general formula of ion-doped single-phase full-spectrum emitting phosphors: Ca 9 MgNa(PO 4 ) 7 :0.005Eu 2 + , Weigh 2 g of raw material powder. The mass ratio of each raw material powder is CaCO 3 : (MgCO 3 ) 4 ·Mg(OH) 2 ·5H 2 O:Na 2 CO 3 :NH 4 h 2 PO 4 :Eu 2 o 3 =0.9639:0.1044:0.0569:0.8660:0.0085.

[0029] (2) Put the above-mentioned raw material powder in an agate mortar and grind for 15 to 20 minutes. After the raw material powder is mixed evenly, put the mixture in a crucible, and place the crucible in a muffle furnace. Medium sintering for 10h.

[0030] (3) Take out the sintered sample, cool it, put it in an agate mortar and grind it into powder again to obtain a precursor.

[0031] (4) The precursor and the aluminum powder were weighed according to the mass ratio of 1:0.3, and 1 g...

Embodiment 2

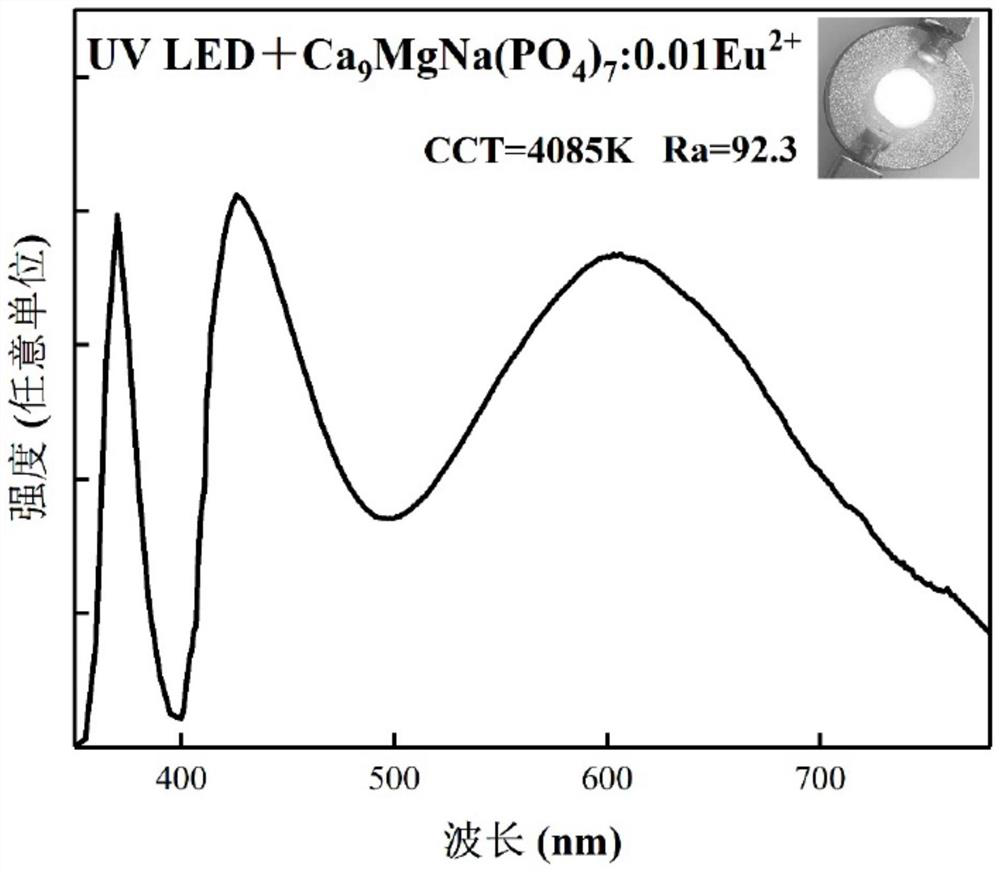

[0036] a kind of Eu 2+ A preparation method for ion-doped single-phase full-spectrum emission phosphor, comprising the following steps:

[0037] (1) According to Eu 2+ The general formula of ion-doped single-phase full-spectrum emitting phosphors: Ca 9 MgNa(PO 4 ) 7 :0.01Eu 2 + , Weigh 2 g of raw material powder. The mass ratio of each raw material powder is CaCO 3 : (MgCO 3 ) 4 ·Mg(OH) 2 ·5H 2 O:Na 2 CO 3 :NH 4 h 2 PO 4 :Eu2 o 3 =0.9574:0.1043:0.0569:0.8644:0.0170.

[0038] (2) Put the above-mentioned raw material powder in an agate mortar and grind for 15 to 20 minutes. After the raw material powder is mixed evenly, put the mixture in a crucible, and place the crucible in a muffle furnace. Medium sintering for 10h.

[0039] (3) Take out the sintered sample, cool it, put it in an agate mortar and grind it into powder again to obtain a precursor.

[0040] (4) The precursor and the aluminum powder were weighed according to the mass ratio of 1:0.3, and 1 g of...

Embodiment 3

[0046] a kind of Eu 2+ A preparation method for ion-doped single-phase full-spectrum emission phosphor, comprising the following steps:

[0047] (1) According to Eu 2+ The general formula of ion-doped single-phase full-spectrum emitting phosphors: Ca 9 MgNa(PO 4 ) 7 :0.02Eu 2 + , Weigh 2 g of raw material powder. The mass ratio of each raw material powder is CaCO 3 : (MgCO 3 ) 4 ·Mg(OH) 2 ·5H 2 O:Na 2 CO 3 :NH 4 h 2 PO 4 :Eu 2 o 3 =0.9443:0.1039:0.0568:0.8613:0.0339.

[0048] (2) Put the above-mentioned raw material powder in an agate mortar and grind for 15 to 20 minutes. After the raw material powder is mixed evenly, put the mixture in a crucible, and place the crucible in a muffle furnace. Medium sintering for 10h.

[0049] (3) Take out the sintered sample, cool it, put it in an agate mortar and grind it into powder again to obtain a precursor.

[0050] (4) The precursor and the aluminum powder were weighed according to the mass ratio of 1:0.3, and 1 g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com