Interior component of a vehicle

An inner chamber and component technology, applied in the field of inner chamber components, can solve the problems of complex design freedom of air guide sheet manufacturing, and achieve the effect of simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

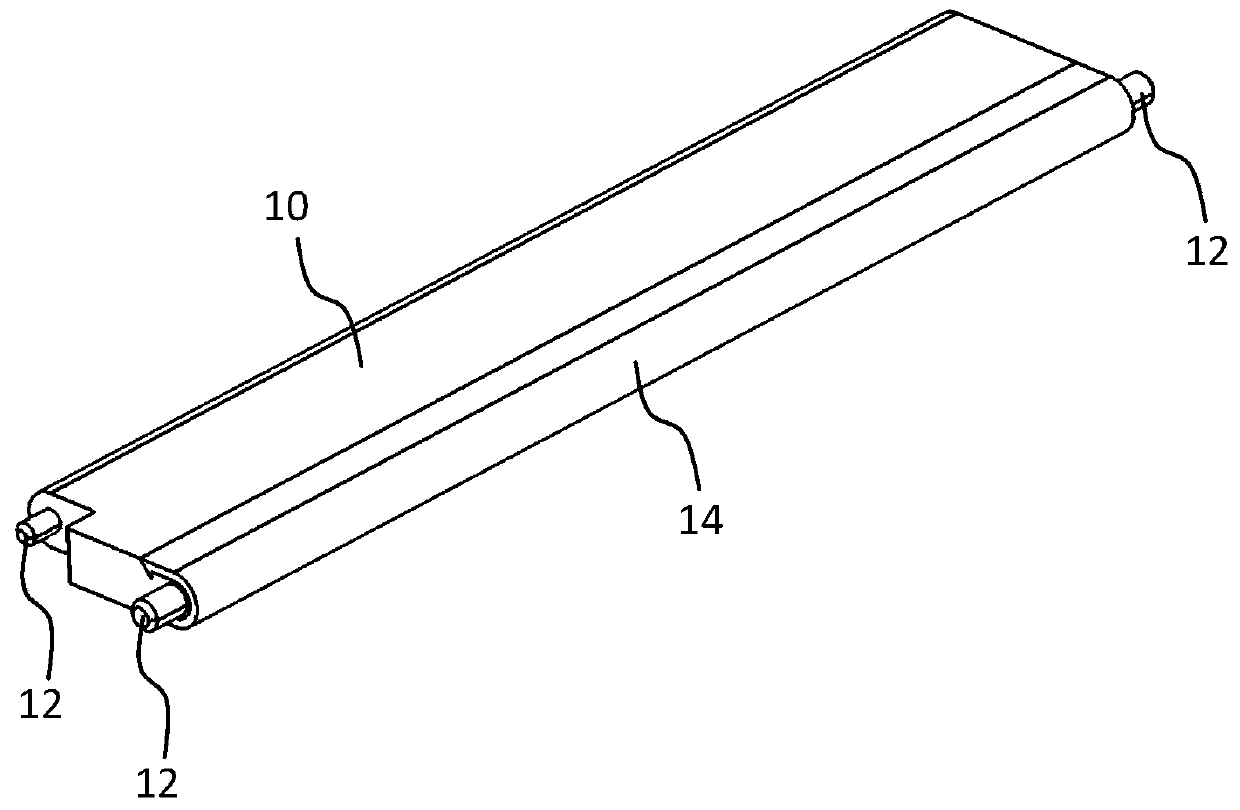

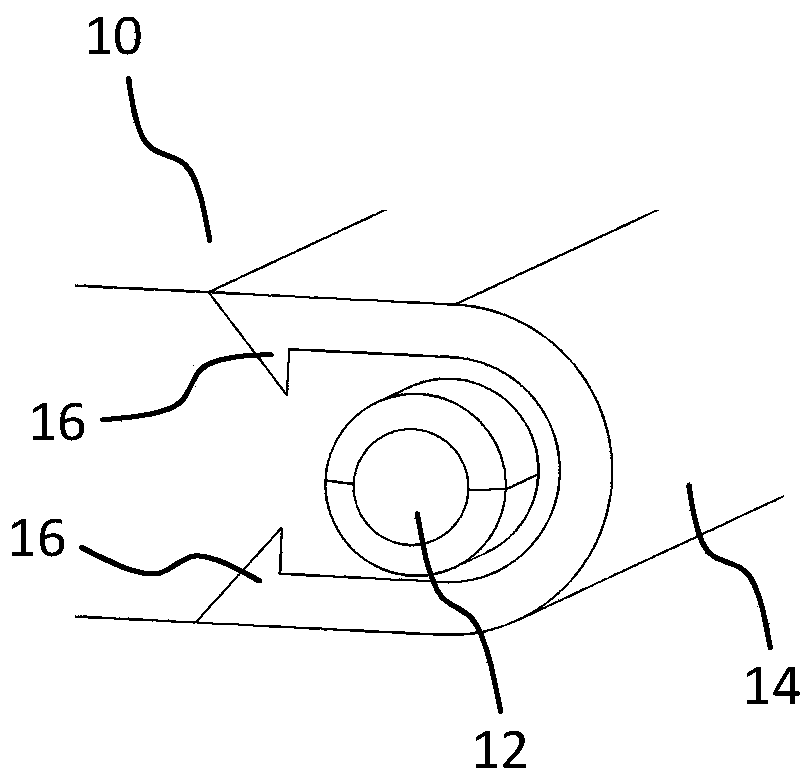

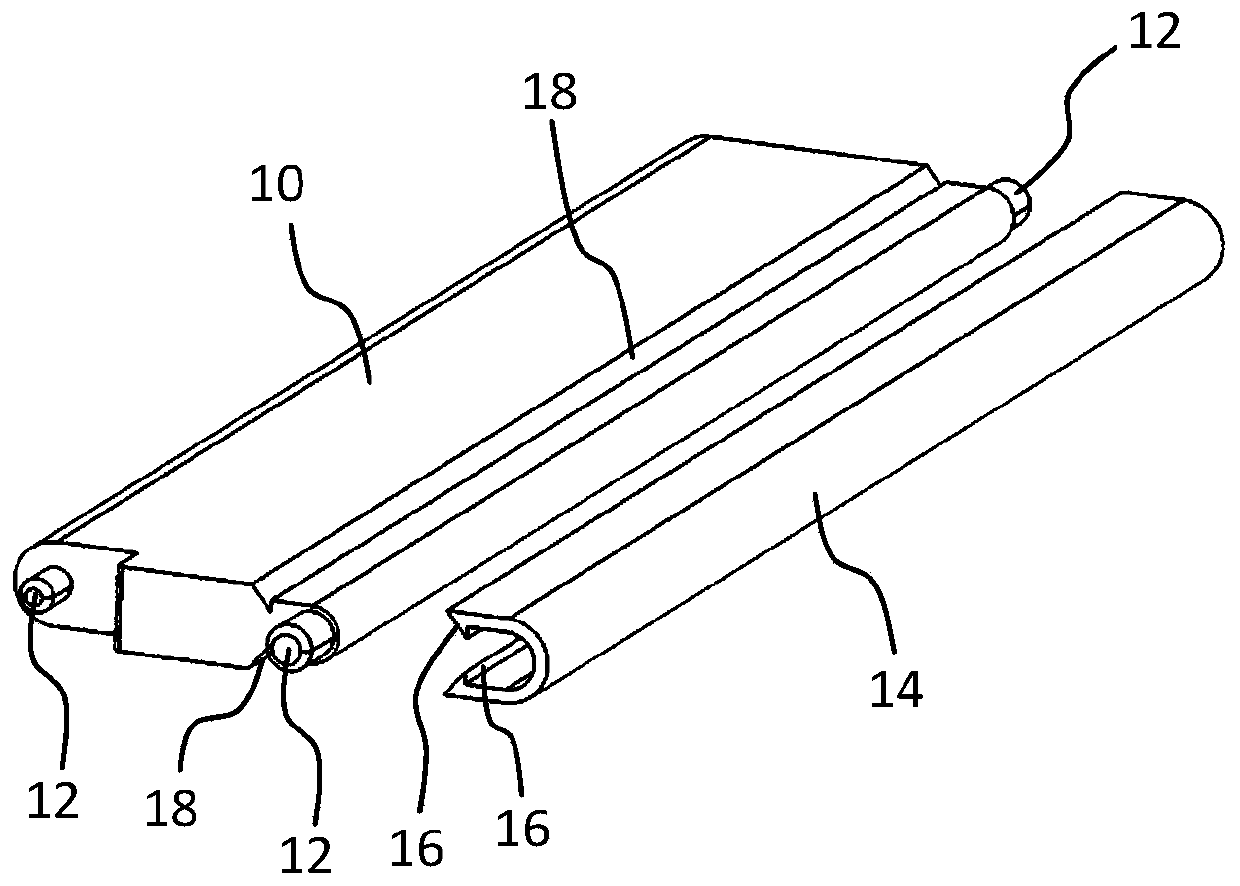

[0035] exist figure 1 The interior part of the invention shown in is an air guide vane for an air vent of a vehicle such as a passenger car or a truck. The air guide vane has a base body 10 , at the opposite end sides of which are formed bearing journals 12 , via which bearing journals the air guide vane is pivotably mounted on the housing of the air vent. The base body 10 is made of plastic, in the present case produced in a plastic injection molding method. It can be, for example, a glass-fibre-reinforced plastic. The substrate 10 has an elongated shape with a length to thickness ratio of at least 3:1.

[0036] In the example shown, a decorative element 14 produced by extrusion is arranged on the base body 10 . The trim element 14 has a U-shaped cross section and, in the example shown, completely covers the front edge of the main body 10 , which in the installed state faces the vehicle interior. The decorative element 14 is also made of plastic, in the present case for e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com