Cement waterproof mortar and preparation method thereof

A waterproof mortar and cement technology, which is applied in the direction of building components, building insulation materials, etc., can solve the problems of reducing the weight of waterproof mortar, and achieve the effects of improving waterproof effect, reducing penetration, and reducing construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

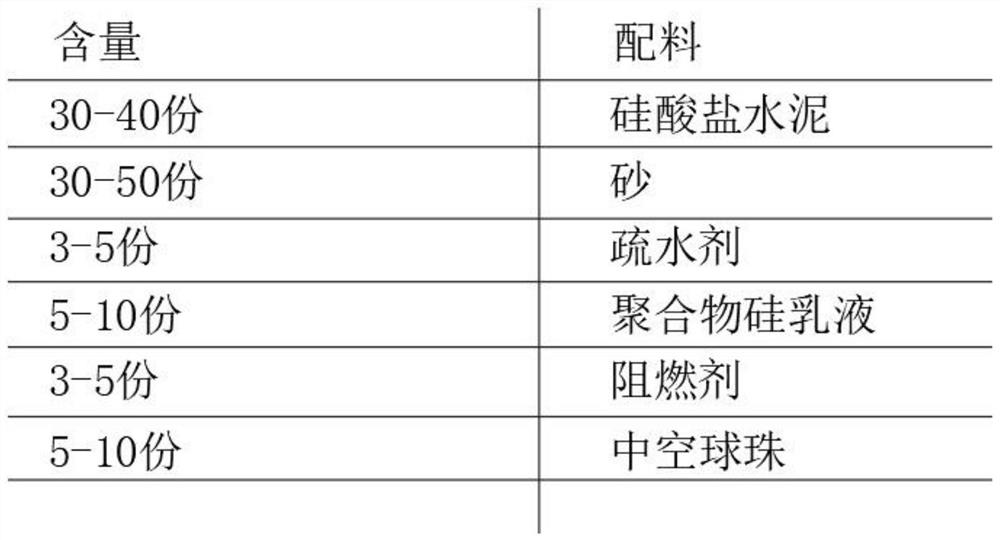

[0046] see figure 1 , a cement waterproof mortar, comprising the following ingredients in parts by mass: 30-40 parts of Portland cement, 30-50 parts of sand, 3-5 parts of hydrophobic agent, 5-10 parts of polymer silica latex powder, 3- 5 parts of flame retardant, 5-10 parts of hollow balls, the particle size of hollow balls is 3-5mm.

[0047] Polymer silicon emulsion is one or more mixtures of ethylene, vinyl chloride and vinyl laurate ternary copolymer latex powder, vinyl acetate and tertiary carbonic acid ethylene copolymer latex powder, vinyl acetate and ethylene copolymer latex powder, sand is selected The fine sand in the downstream section of the river, and keep the sand particle size not higher than 1mm, so that the particle size is finer, thereby effectively avoiding the formation of voids inside the waterproof layer, so that the waterproof effect is better.

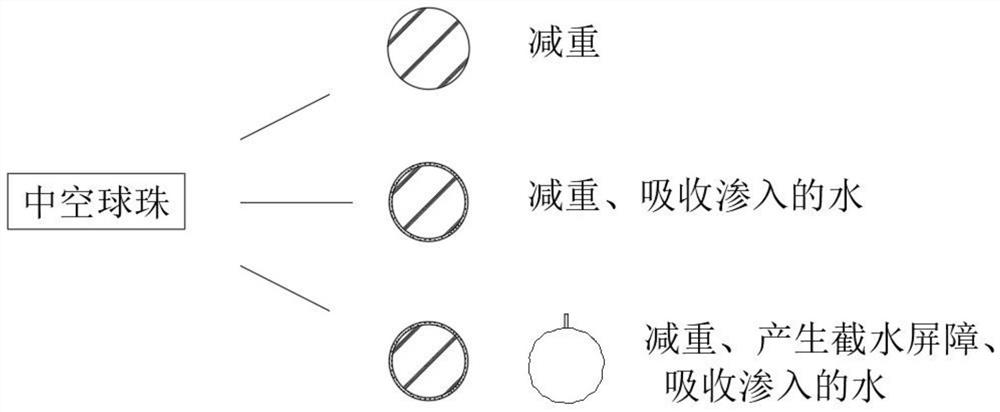

[0048] see figure 2 , The hollow ball is a hollow glass ball.

[0049] A kind of cement waterproof mortar,...

Embodiment 2

[0053] see figure 2 , The hollow ball is a polywater emulsion ball.

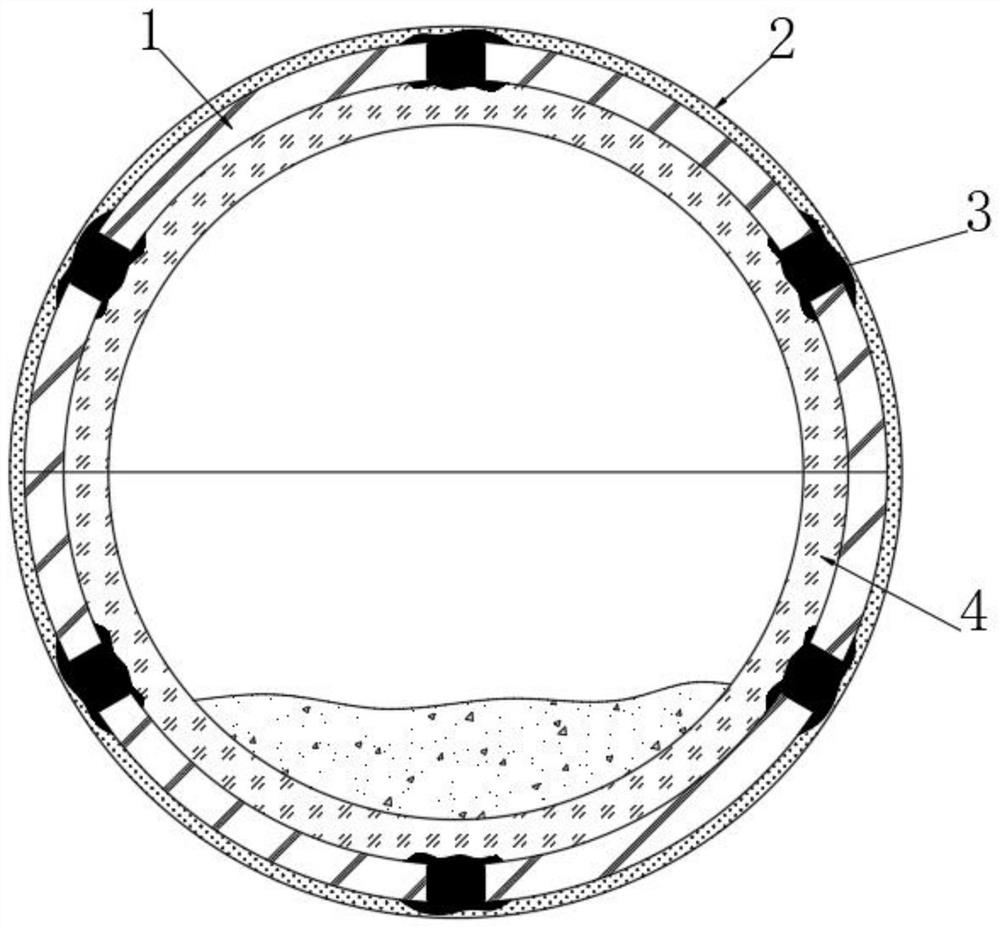

[0054] see image 3 The polywater emulsion ball includes two glass hemispheres 1 bonded to each other. The glass hemisphere 1 is a porous structure, and the pores of the glass hemisphere 1 are wrapped with a water-absorbing layer 3. The inner wall of the glass hemisphere 1 is coated with a water-absorbing layer 4. The glass hemisphere 1 The outside is wrapped with an outer protective layer 2, and the glass hemisphere 1 is also filled with water-absorbing powder, such as Figure 4 , the outer protective layer 2 is made of whole starch degradable material, and the water diversion layer 3 is made of water-soluble material. When only using polywater emulsion balls, when the waterproof layer is formed for a period of time, the outer protective layer 2 gradually degrades, making the porous The glass hemisphere 1 is exposed. When water seepage occurs, when water seeps into the glass hemisphere 1 near the crack, ...

Embodiment 3

[0059] see figure 2 , Hollow balls are anti-seepage milk balls and polywater milk balls.

[0060] When in use, before construction, it is used in the same way as ordinary cement, adding water to make a slurry for use.

[0061] It is also worth noting that in the third combination method, the milk-resistant balls are not mixed with other raw materials, but are stored separately and used together with waterproof mortar obtained by mixing other raw materials.

[0062] see Figure 5 The milk-resistant ball includes a shaped metal mesh layer 6, the outer end of the shaped metal mesh layer 6 is wrapped with an outer water-absorbing layer 7, the inner wall of the shaped metal mesh layer 6 is attached with an inner protective layer 5, and the inner protective layer 5 is placed with A plurality of water-absorbing resin balls 8, the upper end of the plastic metal mesh layer 6 is fixedly connected with an outer ventilation rod 9, the end of the inner sheath 5 is fixedly connected with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com