Plywood adhesive and gluing production process thereof

A production process and adhesive technology, applied in the direction of adhesive types, hydrocarbon copolymer adhesives, manufacturing tools, etc., can solve the problems of long manufacturing cycle, moldy adhesive, long working hours, etc., to simplify manufacturing Steps to achieve the effect of preventing mildew and shortening the manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

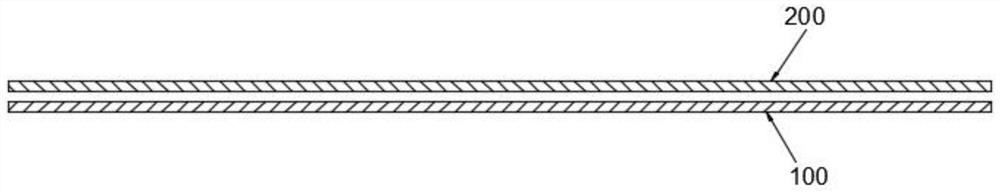

[0044] Example 1: Reference figure 1 The adhesive for plywood shown is a roll material, including a main body layer 100 and a functional layer 200 covering the main body layer 100 . In this embodiment, the functional layer 200 covers one surface of the main body layer 100 , while in some other embodiments, the functional layer 200 may cover two surfaces of the main body layer 100 .

[0045] The main body layer 100 is any substrate-free hot-melt adhesive film in the prior art. Preferably, the main body layer 100 is a substrate-free EVA adhesive film or a substrate-free PA adhesive film. For example, no substrate type EVA film.

[0046] The functional layer 200 is an antifungal agent film. Specifically, the functional layer 200 is formed by spraying or rolling a microemulsion type antifungal agent (such as an isothiazolinone microemulsion) on the unrolled main body layer 100, and then curing through a low-temperature thermal tunnel, For example, the passage time of infrared p...

Embodiment 2

[0054] Embodiment 2: The difference between Embodiment 2 and Embodiment 1 is that the thickness of the functional layer 200 is 0.080 mm. The thickness of the veneer 900 bonded in this embodiment is 2.0 mm, and the veneer is rotary-cut fast-growing poplar veneer. The adhesive for plywood in this embodiment needs to process the veneer before gluing and bonding. In the step of veneer treatment, the following stages are sequentially included in the order of production:

[0055] S1. In the veneer drying stage, hot-press drying dries the veneer 900 to a moisture content of 1% to 2%;

[0056] S2. In the wet treatment stage of the veneer surface, the two surfaces of the veneer 900 are wetted by spraying, and the water consumption for the wet treatment of the veneer surface is 43g / ㎡~45g / ㎡ (amount for one side).

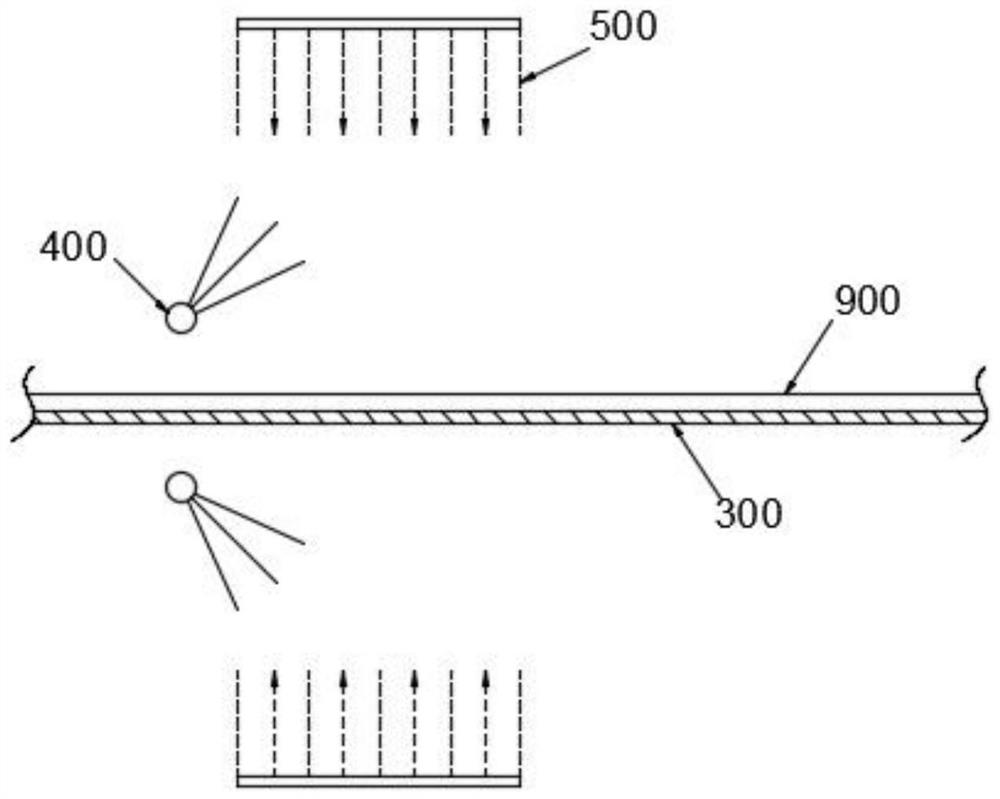

[0057] Wet treatment method reference in the wet treatment stage of the veneer surface figure 2 As shown, the veneer 900 is placed on the mesh belt conveyor 300 to feed, an...

Embodiment 3

[0065] Embodiment 3: The difference between Embodiment 3 and Embodiment 1 is that the thickness of the functional layer 200 is 0.080 mm. The thickness of the veneer 900 bonded in this embodiment is 2.0 mm, and the veneer is rotary-cut fast-growing poplar veneer. The adhesive for plywood in this embodiment needs to process the veneer 900 before gluing and bonding. In the step of veneer processing, the following stages are sequentially included in the production sequence:

[0066] S1. In the veneer drying stage, single-sided hot-press drying dries the veneer 900 to a moisture content of 1% to 2%. The heated surface is surface A, the other surface of the veneer 900 is surface B, and the average moisture content of the side A is is 1%, and the average moisture content of side B is 2%;

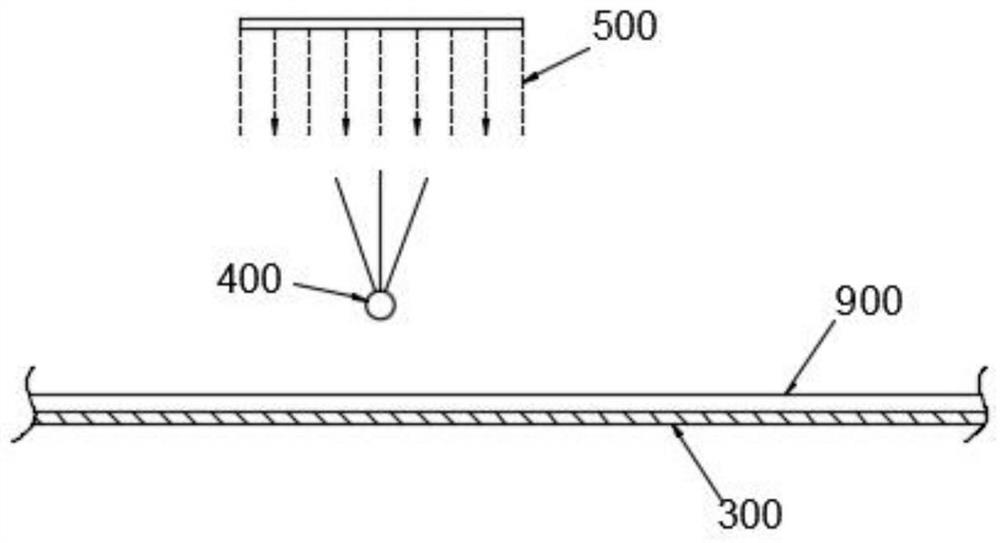

[0067] S2. During the wet treatment stage of the veneer surface, the side B of the veneer 900 is wetted by roller coating or spraying, and the water consumption for the wet treatment of the veneer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com