Optical blanking structure for refrigeration type infrared detector

An infrared detector and refrigeration type technology, which is applied to the surface coating liquid device, pretreatment surface, coating and other directions, can solve the influence of film forming quality, affect the uniformity of film forming thickness, and the uniformity of coating layer thickness is easy There are problems such as deviation, to achieve the effect of improving smoothness and gloss, avoiding unstable curing of the surface layer, and ensuring the uniformity of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

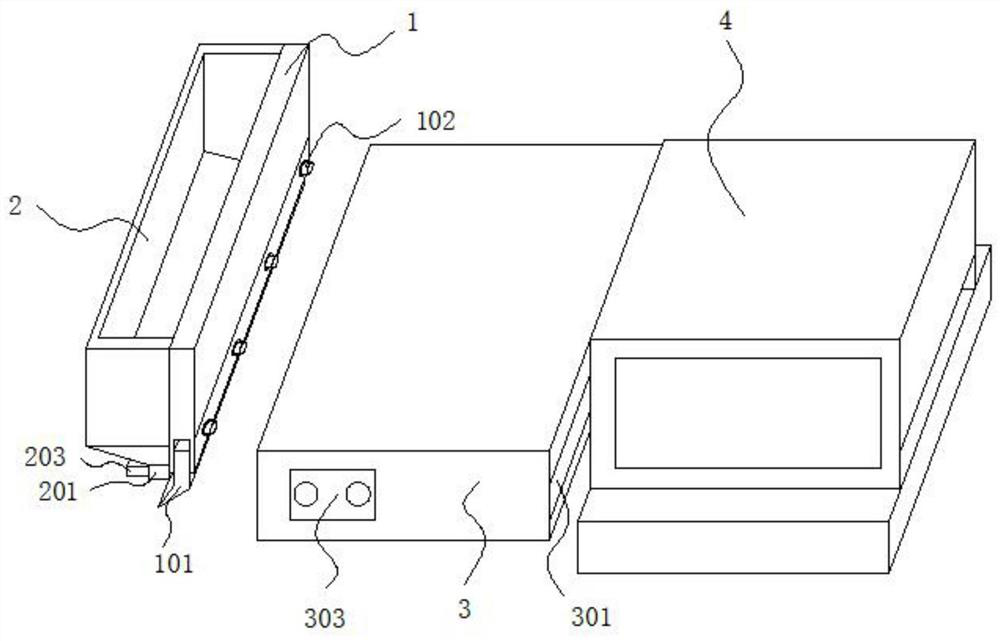

[0021] An optical blanking structure for cooling infrared detectors, comprising a mounting frame and a UV curing machine, a scraper is detachably connected to the bottom of the mounting frame, a storage box is fixedly connected to one side of the surface of the mounting frame, and the The bottom of the material storage box is fixedly connected with a discharge pipe, and a chute is provided in the horizontal direction inside the discharge pipe, and a baffle is inserted inside the chute, and a threaded hole is provided at the bottom of the discharge pipe, and the threaded hole Bolts are screwed inside, and the top of the bolts touches the bottom of the baffle. A pretreatment box is installed between the installation frame and the UV curing machine. Through holes are opened on both sides of the pretreatment box. The pretreatment A heating wire is installed at the bottom inside the box.

[0022] Preferably, an adjusting screw is detachably connected to the bottom of the mounting f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com