Modified Beta molecular sieve, and preparation method and application thereof

A molecular sieve and modification technology, applied in the direction of molecular sieve and alkali exchange compound, molecular sieve catalyst, catalyst containing molecular sieve, etc., can solve the problems of low olefin yield and selectivity, insufficient cracking ability of heavy and inferior crude oil, etc., to improve the pore structure , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

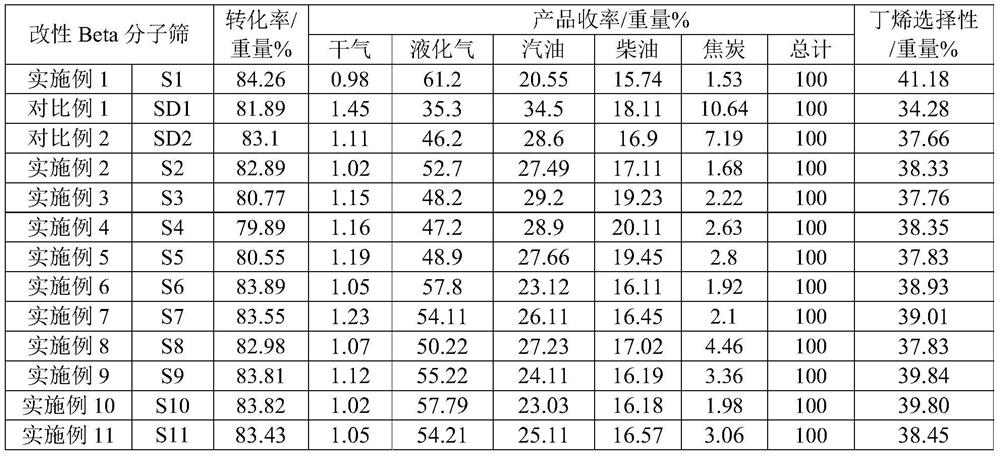

Examples

Embodiment approach

[0038] According to a preferred embodiment of the present invention, in the modified Beta molecular sieve, the mesopore volume with a pore diameter of 5 nm to 20 nm accounts for more than 85% of the total mesopore volume, more preferably not less than 90%, for example, 90% to 90% of the total mesopore volume. 96%. In this preferred situation, the pore structure of the modified Beta molecular sieve is conducive to improving the catalytic performance of the modified Beta molecular sieve in the catalytic cracking reaction.

[0039] According to the present invention, preferably, the specific surface area of the modified Beta molecular sieve is greater than 500m 2 / g, preferably greater than 530m 2 / g, for example, it can be 530-620m 2 / g. In this preferred situation, it is beneficial to improve the catalytic performance of the modified Beta molecular sieve in the catalytic cracking reaction. In the present invention, the specific surface area is measured by the BET adsorptio...

specific Embodiment approach

[0068] The present invention has a wide selection range for the first solvent described in step (1), as long as the environment in which the Beta molecular sieve contacts with alkali and alkaline earth metal elements can be provided. Preferably, the first solvent is water. The present invention has no particular limitation on the water, which can be water of various hardness, and commonly used tap water, distilled water, purified water and deionized water can all be used. In a specific embodiment of the present invention, the first solvent is neutral water, which is also called distilled water.

[0069] The present invention has a wide range of options for the amount of the first solvent, and can be properly selected according to the amount of the Beta molecular sieve and the compound of alkali and alkaline earth metal, as long as the environment that makes the contact in step (1) can be provided . Preferably, relative to 100 parts by weight of the Beta molecular sieve, the ...

Embodiment 1

[0123] Prepare modified Beta molecular sieve according to the method of the present invention, concrete steps are as follows:

[0124] (1) Take Beta molecular sieve (SiO 2 / Al 2 o 3 Molar ratio is 25; Sodium oxide content 0.05% by weight, the same below) 100g (dry weight), add 600g neutral water (also known as distilled water in the present invention), 20g NaOH solution (molar concentration is 0.833mol / L) and 20g of MgO was heated to 70°C, and after contact reaction for 2 hours, it was cooled to room temperature, then filtered, washed and dried successively to obtain a solid product.

[0125] (2) get the solid product 80g (dry basis weight) that step (1) obtains, make a slurry with 640g water, then add the H of 20% by weight that the weight content of 40g 2 SO 4 1. 60g of oxalic acid, heated up to 70°C, after acid treatment for 2 hours, followed by filtration, washing and drying;

[0126] (3) Take step (2) to obtain 50g (dry basis weight) of product, add 200g neutral wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com