Regularly coordinated cobalt or iron-doped cobalt-based electrocatalyst and its preparation and use

An electrocatalyst, iron doping technology, applied in fuel cell type half cells and secondary cell type half cells, circuits, electrical components, etc. Clear and clear, coordination rules, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

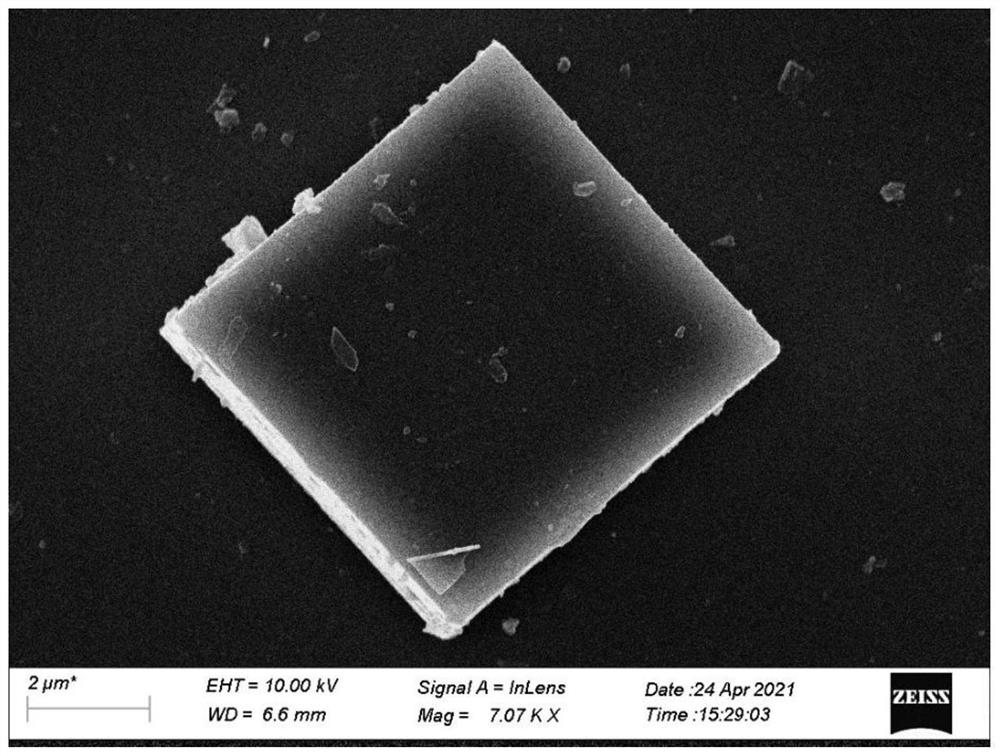

[0074] A preparation method of a regularly coordinated cobalt-based electrocatalyst, comprising the following steps:

[0075] A. Mix 4.37g of cobalt nitrate hexahydrate with a certain amount of formamide, stir to dissolve it, and obtain 30ml of pink solution, which is recorded as the first solution, and the concentration of the formamide solution of cobalt salt is: 0.5M.

[0076] B, feed ammonia into a certain amount of formamide until the concentration of ammonia is 0.5M, measure the formamide solution of 30ml of ammonia, and denote it as the second solution.

[0077] C. Pour the first solution into the second solution, stir and mix evenly, place in a polytetrafluoroethylene reaction kettle, and heat to 160 degrees Celsius in an oven for 6 hours.

[0078] D. After the reaction is finished, the temperature is naturally cooled, the solid-liquid mixture is taken out, the solid-liquid mixture is separated by centrifugation, the solid product is collected, and the solid product is...

Embodiment 2

[0087] A preparation method of a regularly coordinated cobalt-based electrocatalyst, comprising the following steps:

[0088] A. Mix 1.75g of cobalt nitrate hexahydrate with a certain amount of formamide, stir to dissolve it, and obtain 60ml of pink solution, which is recorded as the first solution, and the concentration of the formamide solution of cobalt salt is 0.1M.

[0089] B. Mix 4ml of ethylenediamine with a certain amount of formamide, and stir evenly to obtain 30ml of solution, which is designated as the second solution, and the concentration of the formamide solution of ethylenediamine is 2M;

[0090] C. Pour the first solution into the second solution, stir and mix evenly, place in a polytetrafluoroethylene reaction kettle, and heat to 210 degrees Celsius in an oven for 12 hours.

[0091] D. After the reaction is finished, the temperature is naturally cooled, the solid-liquid mixture is taken out, the solid-liquid mixture is separated by centrifugation, the solid ...

Embodiment 3

[0098] A preparation method of a regularly coordinated cobalt-based electrocatalyst, comprising the following steps:

[0099] A. Mix 17.46g of cobalt nitrate hexahydrate with a certain amount of formamide, stir to dissolve it, and obtain 30ml of dark red solution, which is denoted as the first solution, and the formamide solution concentration of cobalt salt is 2M.

[0100] B. Mix 0.12g of sodium hydroxide with a certain amount of formamide, stir to dissolve it, and obtain 30ml of dissolved

[0101] solution, denoted as the second solution. The concentration of sodium hydroxide in formamide solution is 0.1M;

[0102] C. Pour the first solution into the second solution, stir and mix evenly, place in a polytetrafluoroethylene reactor, heat to 110 degrees Celsius, and keep for 24 hours.

[0103] D. After the reaction is finished, the temperature is naturally cooled, the solid-liquid mixture is taken out, the solid-liquid mixture is separated by centrifugation, the solid product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com