Up-and-down type roller drying equipment for biomass fuel

A technology of biomass fuel and drying equipment, which is applied in the direction of drying, drying machine, drying solid materials, etc., can solve the problems of reduced drying efficiency and easy sticking to the wall, so as to improve the drying efficiency and reduce the phenomenon of sticking to the wall Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

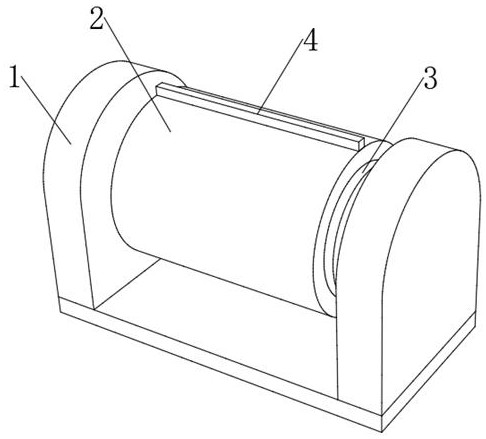

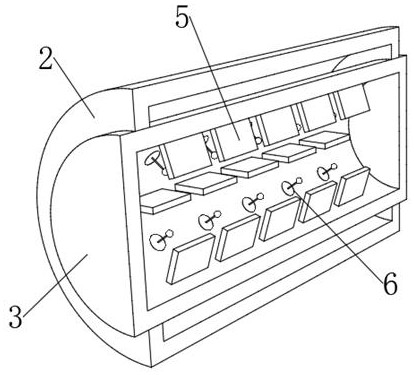

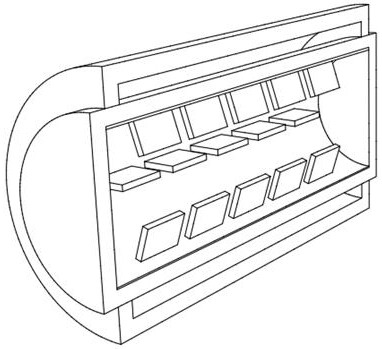

[0042] see Figure 1-4 , a kind of undulating type drum drying equipment for biomass fuel, including a rotary table 1, an inner drum 3 is connected to the rotary table 1, the rotary table 1 can be driven by a built-in motor, and the outer end of the inner drum 3 is provided with a matching The outer heating cylinder 2, the mechanical seal device can be used for sealing between the outer heating cylinder 2 and the inner drum 3, the inner drum 3 can be provided with ventilation holes to facilitate the discharge of water vapor, and the exhaust fan can also be actively installed. The specific ventilation measures are selected by the technicians , the external heating cylinder 2 is fixedly connected with the rotary table 1, the above is the prior art, and the specific structure will not be repeated here. The upper end of the external heating cylinder 2 is fixedly connected with the control box 4, and the control box 4 is embedded with multiple heating devices. The inner wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com