Fuel gas generator

A gas generator and fuel technology, which is applied in jet propulsion devices, machines/engines, rocket engine devices, etc., can solve problems affecting the working performance of gas generators, low combustion efficiency, high temperature, etc., to avoid high temperature and improve combustion efficiency , making precise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

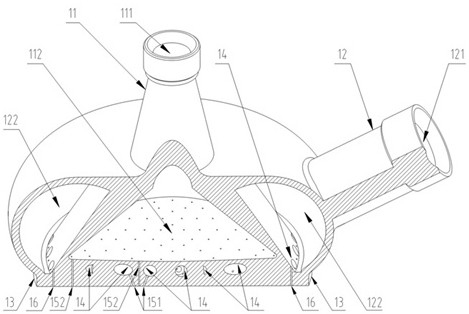

Image

Examples

Embodiment Construction

[0026] The specific embodiment of the present invention is described below in conjunction with accompanying drawing of description;

[0027]The gas generator described in the present invention is applied to a power supply system of a liquid rocket engine. In actual use, the fuel nozzle (12) of the gas generator injector (1) communicates with the fuel storage tank through a pipeline, and the oxidizer nozzle (11) communicates with the oxidant storage tank through a pipeline, thereby providing the gas The generator provides fuel and oxidant; the right port (42) of the three-way elbow (4) of the gas generator is connected to the inlet of the liquid rocket engine power supply system by welding, and the left port (43) is connected to other devices by bolts. For closed state use. The fuel and oxidant are sprayed into the inner cavity of the cylindrical ring (21) of the eccentric spoiler ring (2) through the injector (1), impacted, atomized and burned, and gas is generated after comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com