Equiaxial high-strength zirconium alloy and preparation method thereof

A zirconium alloy, equiaxed technology, applied in the field of alloys, can solve the problems of narrow application range, low strength, and limited application of zirconium alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention provides a method for preparing an equiaxed high-strength zirconium alloy described in the above scheme, comprising the following steps: melting the alloy raw material to obtain a cast alloy billet; the composition of the alloy raw material is determined according to the composition of the equiaxed high-strength zirconium alloy;

[0042] Rolling and deforming the as-cast alloy billet after heat preservation to obtain a densified alloy billet;

[0043] The densified alloy billet is subjected to solid solution treatment to obtain an equiaxed high-strength zirconium alloy.

[0044] The invention melts the alloy raw material to obtain the cast alloy billet.

[0045] In the present invention, there is no special limitation on the type of the alloy raw material, and the alloy raw material well-known to those skilled in the art is used as the zirconium alloy that can achieve the target composition. In the present invention, the alloy raw materials prefer...

Embodiment 1

[0065] According to the alloy composition Zr-0.5Sn (mass percentage) ingredients, take industrial-grade zirconium sponge (Zr, Hf is not separated), tin wire (purity 99.9%) immersed in absolute ethanol, after ultrasonic cleaning, air-dried, placed in non- In the water-cooled copper crucible for consumable vacuum arc melting, the vacuum in the furnace cavity should be pumped to 8×10 -3 Below Pa. After filling high-purity argon as a protective gas (vacuum degree 0.04-0.05MPa) before arc melting, the arc temperature is 1850°C for each melting, and the time for each melting is 4 minutes to ensure uniform composition. After cooling, the ingot is obtained, and then the ingot is turned over for smelting, so that the smelting-casting ingot is repeatedly smelted and turned over 6 times to ensure that the composition of the finally obtained cast alloy billet is uniform.

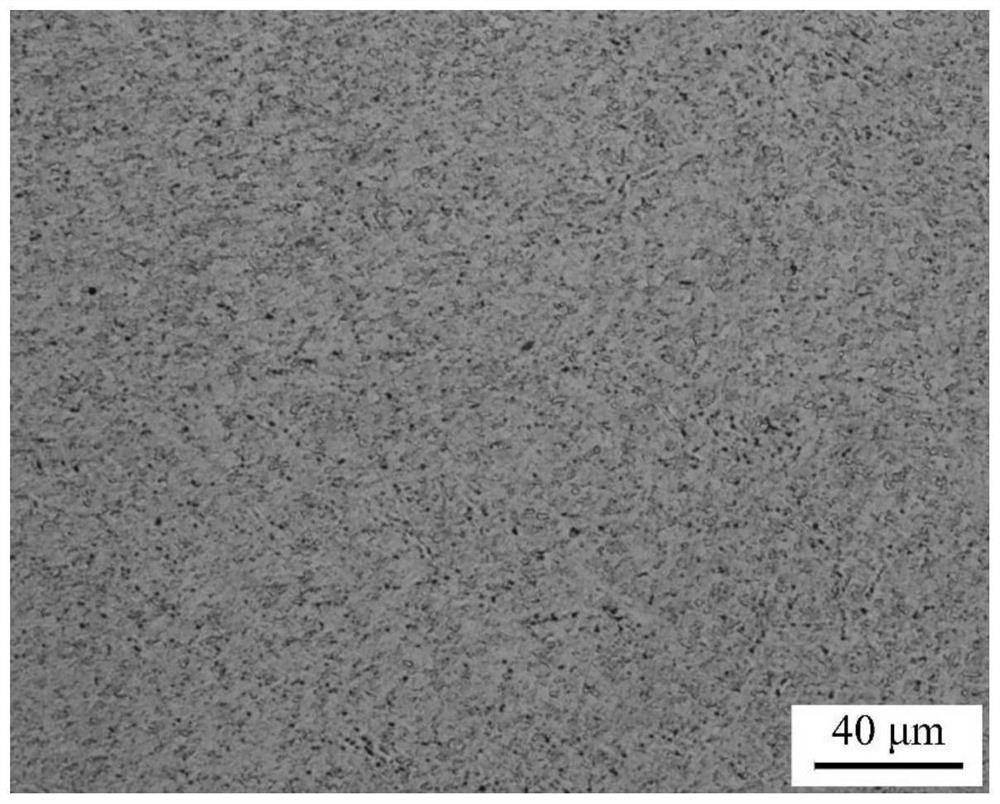

[0066] Put the as-cast alloy billet into a vacuum tube furnace (SK-G06143 Tianjin Zhonghuan Experimental Electric Fu...

Embodiment 2

[0071] According to the alloy composition Zr-1Sn (mass percentage), take industrial-grade sponge zirconium (Zr, Hf is not separated), tin wire (99.9%) and immerse in absolute ethanol, after ultrasonic cleaning, air-dry, put into non-consumable In the water-cooled copper crucible for vacuum arc melting, the vacuum in the furnace cavity should be pumped to 8×10 -3 Below Pa. After filling high-purity argon as a protective gas (vacuum degree 0.04-0.05MPa) before arc melting, the arc temperature is 1850°C for each melting, and the time for each melting is 4 minutes to ensure uniform composition. After cooling, the ingot is obtained, and then the ingot is turned over for smelting, so that the smelting-casting ingot is repeatedly smelted and turned over 6 times to ensure that the composition of the finally obtained cast alloy billet is uniform.

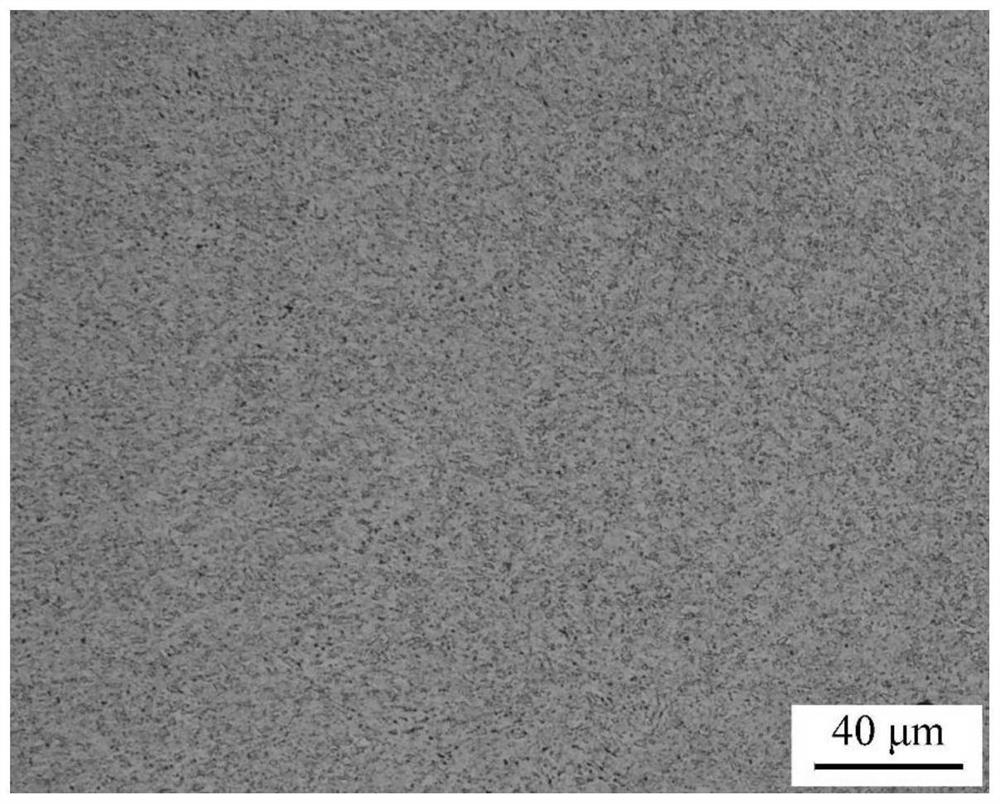

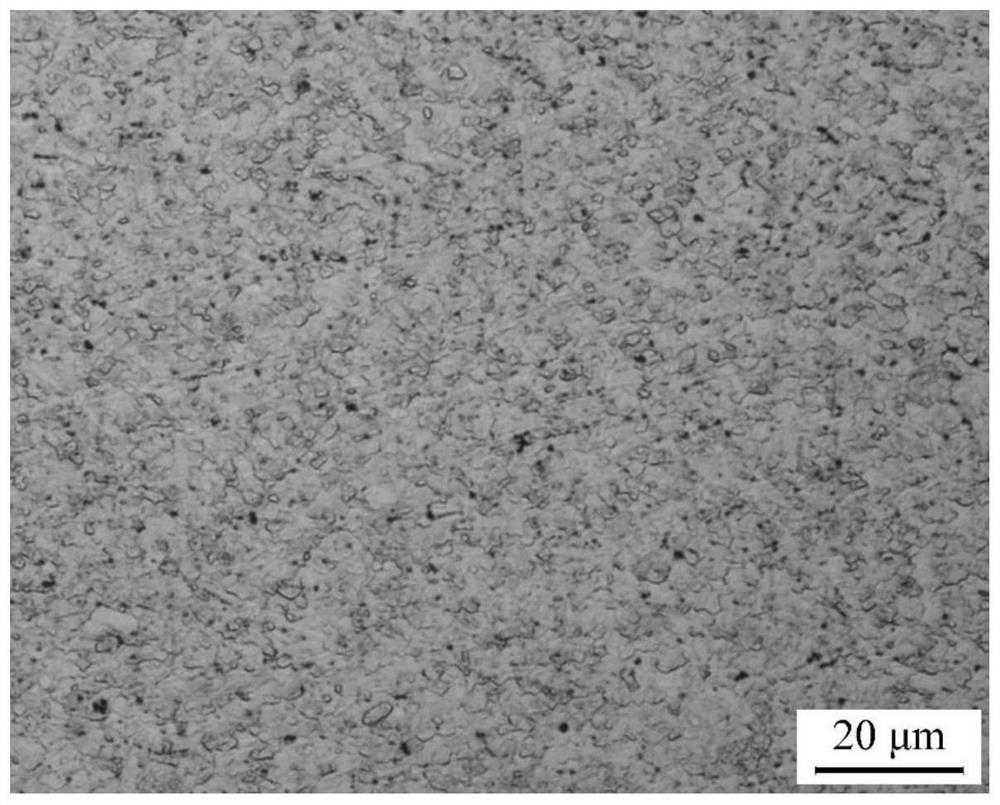

[0072] Put the as-cast alloy billet into a vacuum tube furnace (SK-G06143 Tianjin Zhonghuan Experimental Electric Furnace Co., Ltd.) for h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com