Water-based polyurea composite modified single-component acrylic acid waterproof coating and preparation method thereof

A composite modification, waterproof coating technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of complex preparation method and increased cost, and achieve the effect of simple preparation method, low cost and reduced water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

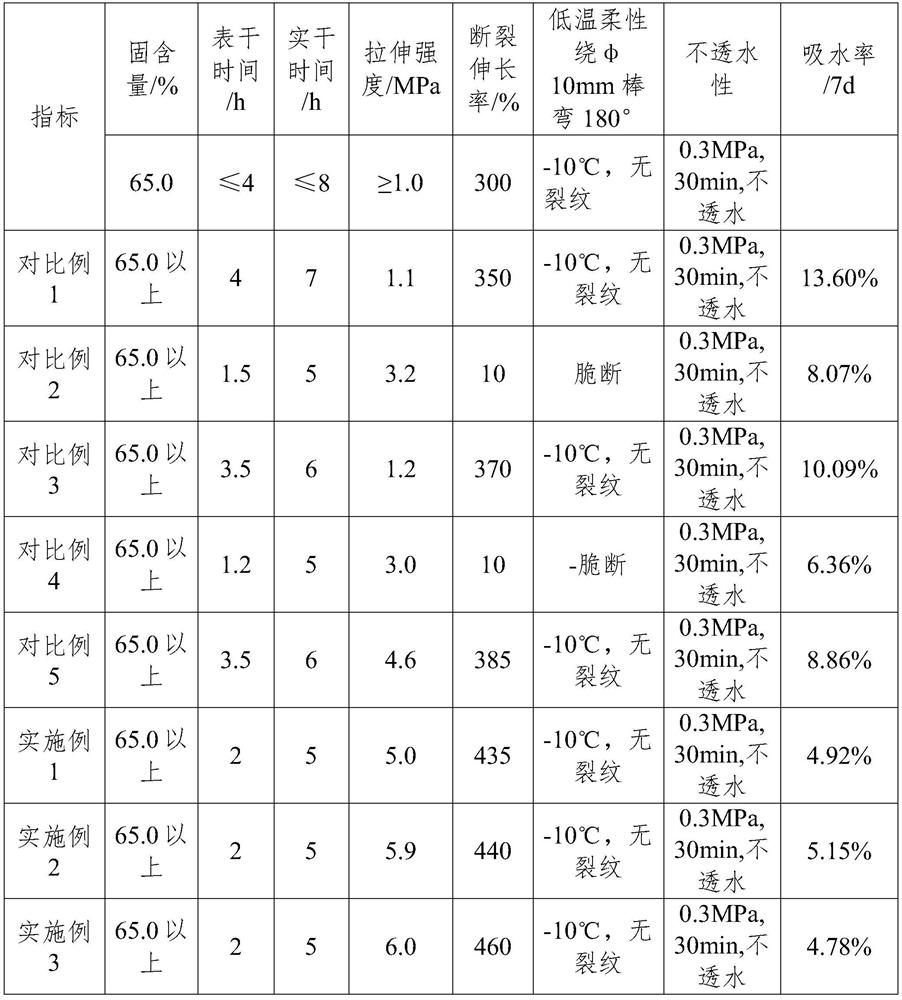

Examples

Embodiment 1

[0040] The preparation method of water-based polyurea composite modified single-component acrylic waterproof coating, the steps are:

[0041] S1 ultrasonically disperse graphene powder with a layer number of 1 and a particle size of 12 μm in deionized water for 45 minutes to obtain a graphene aqueous dispersion;

[0042] S2 Add the graphene water-based dispersion liquid successively to dispersant, silicone defoamer, antifungal agent, under stirring speed 1000r / min, rutile type titanium dioxide, 800 mesh barium sulfate, 800 mesh heavy calcium carbonate, continue to stir for 35min;

[0043] In S3, add pure acrylic acid waterproof emulsion with a glass transition temperature of -20°C and water-based polyurea emulsion with a minimum film-forming temperature of 0°C in sequence, reduce the stirring speed to 600r / min, continue stirring for 30min, and let it stand to obtain a water-based polyurea composite modification. One-component acrylic waterproof coating;

[0044] In this embod...

Embodiment 2

[0046] The preparation method of water-based polyurea composite modified single-component acrylic waterproof coating, the steps are:

[0047] S1 ultrasonically disperse graphene powder with a particle size of 7 μm and 3 layers in deionized water for 60 minutes to obtain a graphene aqueous dispersion;

[0048] S2 adds dispersant, mineral oil defoamer, antifungal agent to graphene aqueous dispersion liquid successively, under stirring speed 800r / min, rutile type titanium dioxide, 800 order barium sulfate, 800 order mica powder, 1000 order talcum powder, Keep stirring for 25min;

[0049] In S3, add pure acrylic acid waterproof emulsion with a glass transition temperature of -20°C and water-based polyurea emulsion with a minimum film-forming temperature of 0°C in sequence, reduce the stirring speed to 500r / min, continue stirring for 25min, and let it stand to obtain a water-based polyurea composite modification. One-component acrylic waterproof coating;

[0050] In this embodime...

Embodiment 3

[0052] The preparation method of water-based polyurea composite modified single-component acrylic waterproof coating, the steps are:

[0053] S1 ultrasonically disperse graphene powder with 2 layers and a particle size of 10 μm in deionized water for 70 minutes to obtain a graphene aqueous dispersion;

[0054] S2 Add the graphene water-based dispersion liquid successively to dispersant, mineral oil defoamer, organic silicon defoamer, under stirring speed 900r / min, rutile type titanium dioxide, 800 mesh barium sulfate, 800 mesh heavy calcium carbonate, 800 mesh Mesh mica powder, 1000 mesh talcum powder, keep stirring for 30min;

[0055] In S3, add pure acrylic acid waterproof emulsion with a glass transition temperature of -20°C and water-based polyurea emulsion with a minimum film-forming temperature of 0°C in sequence, reduce the stirring speed to 400r / min, continue stirring for 35min, and let stand to obtain a water-based polyurea composite modification. One-component acrylic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com