Multifunctional armor protective coating material as well as preparation method and application thereof

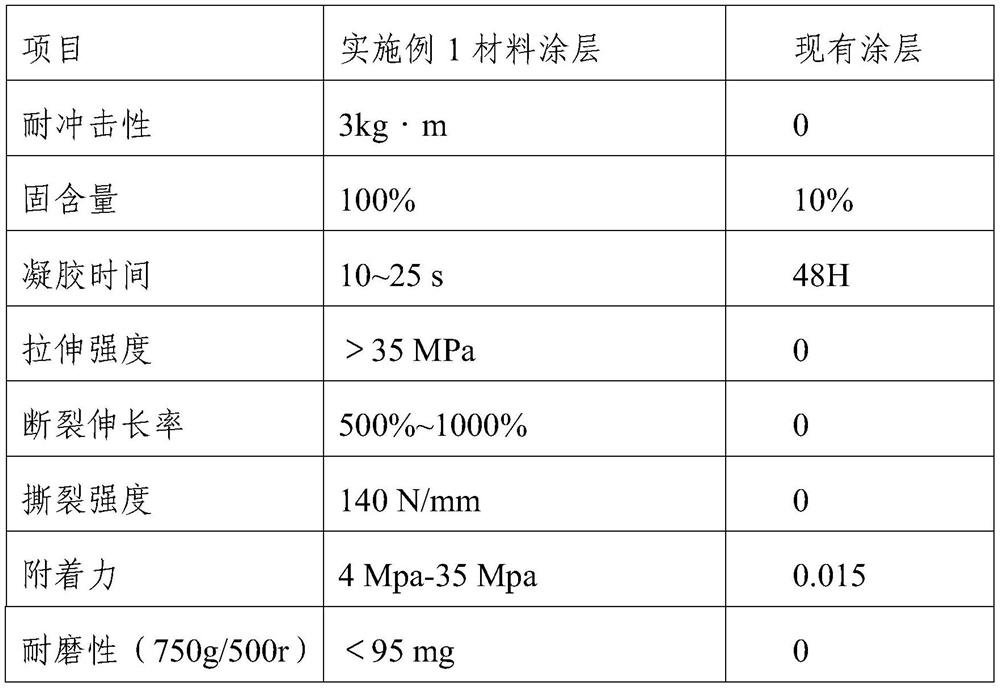

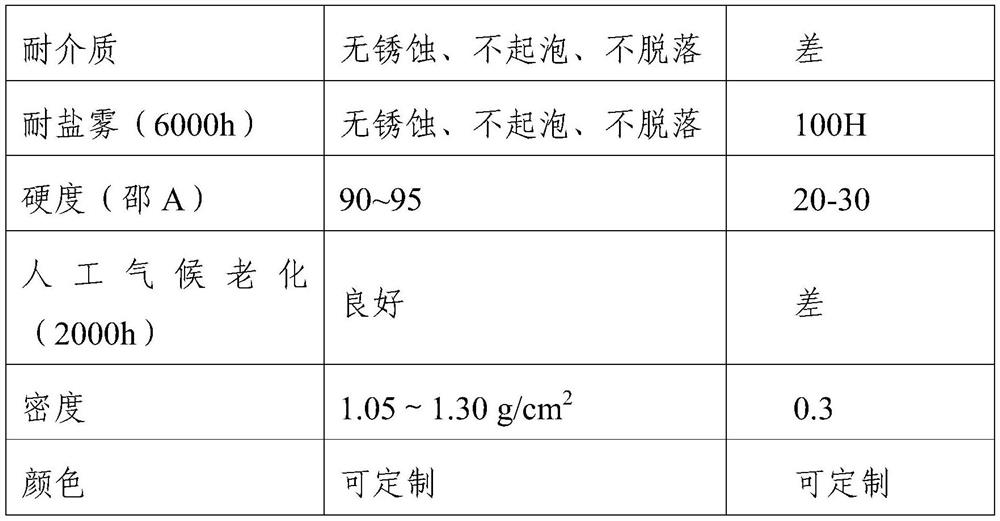

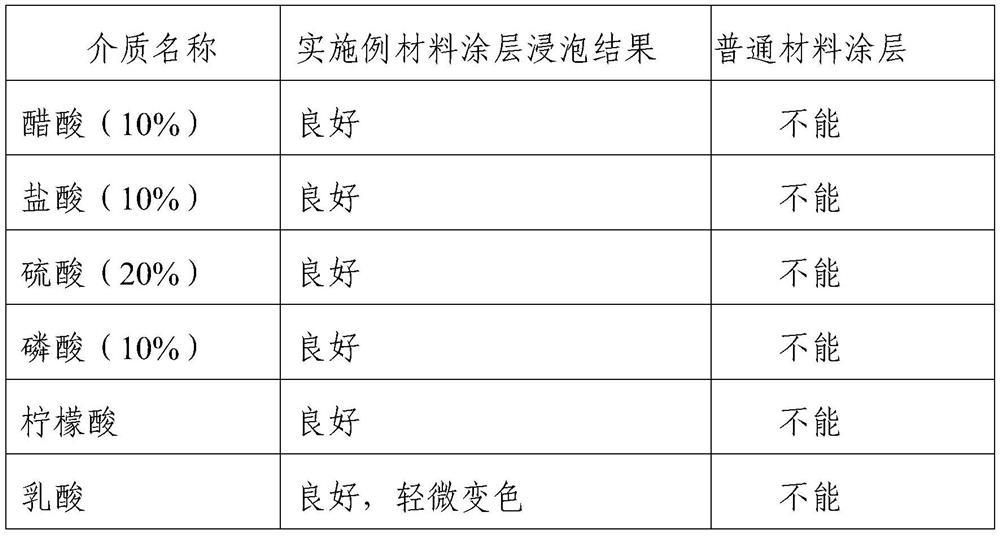

A coating material and armor protection technology, applied in the field of coatings, can solve the problems of anti-corrosion effect, unsatisfactory waterproof treatment, explosion-proof and wear-resistant, and achieve the effects of superior impact resistance, outstanding medium resistance and fast curing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a multifunctional armor protection coating material, which includes a first mixture and a second mixture.

[0038] Wherein, the first mixture is made of the following components in mass percentage: 35% of amino-terminated polyoxypropylene ether (amino-terminated polyether), 10% of liquid amine chain extender diethyltoluenediamine, 3% of pigment paste, Filler Kevlar fiber 1%, additive epoxy resin 1%, water 50%;

[0039] The second mixture is made of the following components in mass percentage: 30% of isocyanate, 25% of oligomer diol polyhexamethylene adipate diol (PHA) and 45% of water.

[0040] After fully mixing the first mixture and the second mixture according to the mass ratio of 1:1, a multifunctional armor protective coating material is obtained.

[0041] In this embodiment, the pigment used is phthalocyanine pigment green.

Embodiment 2

[0043] This embodiment provides a multifunctional armor protection coating material, which includes a first mixture and a second mixture.

[0044] Wherein, the first mixture is made of the following components in mass percentage: 45% of amino-terminated polyoxypropylene ether (amino-terminated polyether), 15% of liquid amine chain extender diethyltoluenediamine, 5% of pigment paste, Filler Kevlar fiber 3%, additive epoxy resin 3%, water 29%.

[0045] The second mixture is made of the following components in mass percentage: 35% of isocyanate, 30% of oligomer diol polybutylene adipate diol PBA and 35% of water.

[0046] After the above-mentioned first mixture and the second mixture are fully mixed according to a mass ratio of 1:1, a multifunctional armor protective coating material is obtained.

[0047] In this embodiment, the pigment is phthalocyanine pigment red.

Embodiment 3

[0049] This embodiment provides a multifunctional armor protection coating material, which includes a first mixture and a second mixture.

[0050] Wherein, the first mixture is made of the following components in mass percentage: 55% of amino-terminated polyoxypropylene ether (amino-terminated polyether), 20% of liquid amine chain extender diethyltoluenediamine, 7% of pigment paste, Filler Kevlar fiber 5%, additive epoxy resin 5%, water 8%.

[0051] The second mixture is made of the following components in mass percentage: 35% of isocyanate, 30% of triol polyether triol (330N) and 35% of water.

[0052] After fully mixing the first mixture and the second mixture according to the mass ratio of 1:1, a multifunctional armor protective coating material is obtained.

[0053] In this embodiment, the pigment is phthalocyanine pigment green.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com