Europium (iii) metal-organic framework eu-mof probe material and its preparation method and application

A technology of metal-organic frameworks and probes, which is applied in the fields of material analysis, material excitation analysis, and material analysis through optical means, etc. It can solve the problems of limiting the application range of materials, low stability of materials, and strict synthesis conditions, etc., and achieves excellent results. Selectivity and anti-interference ability, easy control of chemical composition, high sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

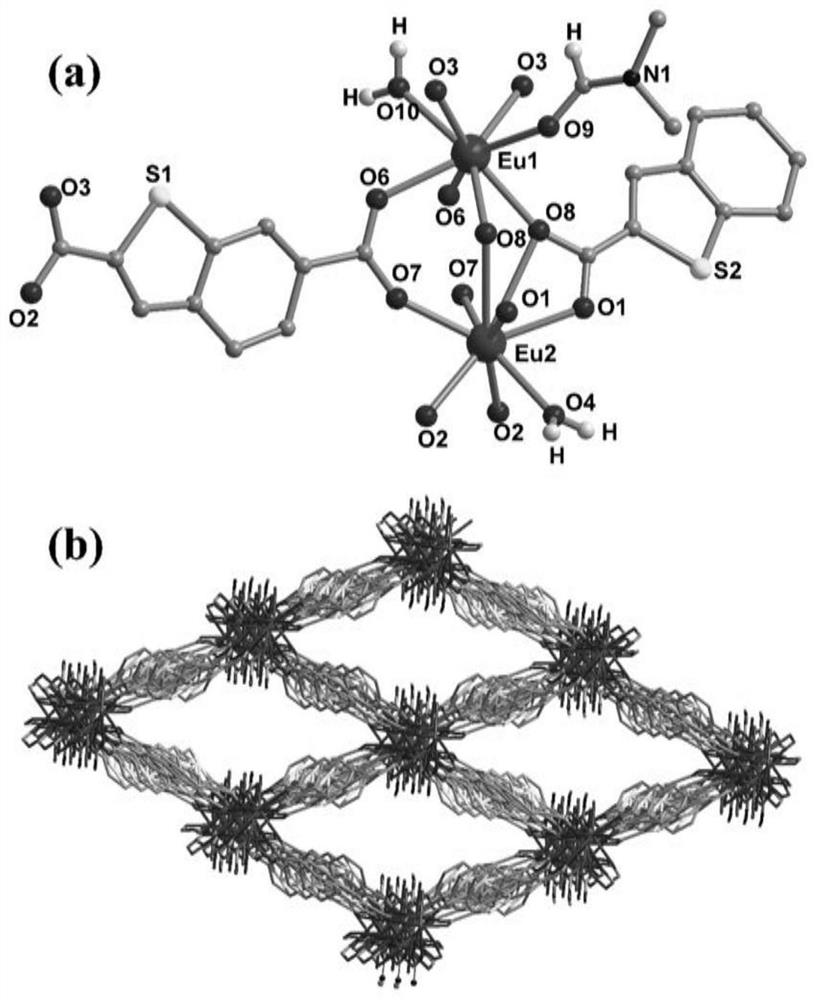

[0040] The metal-organic framework Eu-MOF material provided by the present invention, its preparation method comprises the following steps:

[0041] 1) The ligand 2,6-benzothiophene dicarboxylic acid H 2 L and Eu (NO 3 ) 3 ·6H 2 O is added in the reactor, mixed;

[0042] When implemented, H 2 L and Eu (NO 3 ) 3 ·6H 2 The molar ratio of O can be any ratio within 1:1 to 1.5:1;

[0043] The reaction kettle provided by the invention is a high pressure reaction kettle or a glass reaction bottle;

[0044] 2) continue to add N,N-dimethylformamide DMF and H in the reactor 2 Mixed solution of O, mixed and sealed;

[0045] When implemented, DMF and H 2 The molar ratio of O can be any ratio from 1:1 to 1:2; DMF to H 2 The mass ratio of L is any ratio within 100:1 to 120:1;

[0046] 3) The sealed reactor in step 2) was placed in a blast drying oven, and with a heating rate of 0.5°C / min, a constant temperature reaction was performed for 4 hours when the temperature was raised ...

Embodiment 1

[0049] 1) The mass of 0.0222g ligand 2,6-benzothiophene dicarboxylic acid H 2 L and Eu(NO) with a mass of 0.0446 g 3 ) 3 ·6H 2 0 is put into the autoclave with a volume of 25mL, respectively, and mixes;

[0050] In this embodiment, the high-pressure reaction kettle is lined with polytetrafluoroethylene, and the outer material is stainless steel; 2,6-benzothiophene dicarboxylic acid and Eu(NO) 3 ) 3 ·6H 2 The molar ratio of O is 0.1mmol:0.1mmol=1:1;

[0051] 2) continue to add the N,N-dimethylformamide DMF of 2.5mL and the H of 2.5mL in the autoclave 2 Mixed solution composed of O, mixed and sealed; DMF and H 2 O volume ratio is 1:1; DMF and H 2 The mass ratio of L is 100:1;

[0052] 3) Place the sealed autoclave in step 2) in a blast drying oven, and at a heating rate of 0.5°C / min, the temperature of the drying oven is raised from 20°C to 80°C within 2 hours, and the reaction is performed at a constant temperature for 4 hours. hour; then the cooling rate of 1°C / min r...

Embodiment 2

[0054] The difference between this example and Example 1 is that the cooling time in step 3) is 10h, that is, a cooling rate of 0.1°C / min is used to reduce the temperature of the drying oven from 80°C to 20°C. The crystals were weighed and the Eu-MOF probe material yield was calculated to be 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com