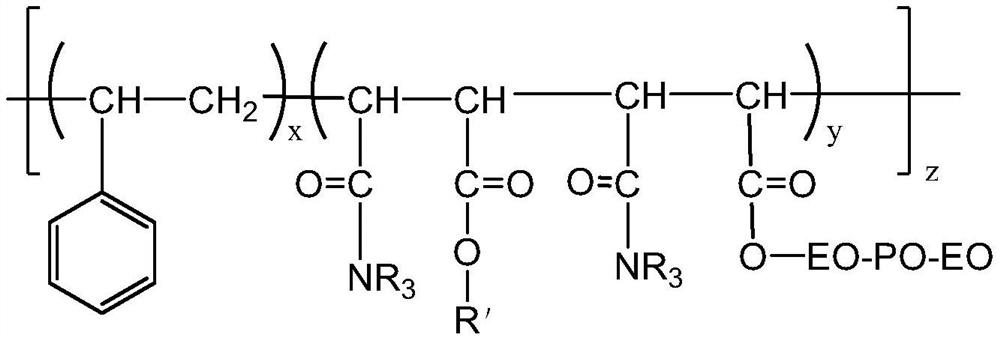

Preparation method and application of hyperbranched polymer water soluble dispersant

A hyperbranched polymer, water-based dispersant technology, applied in coatings, pigment pastes, anti-corrosion coatings, etc., can solve the adverse effects of paint film appearance, hardness and aging resistance, not widely applicable, poor long-term stability, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

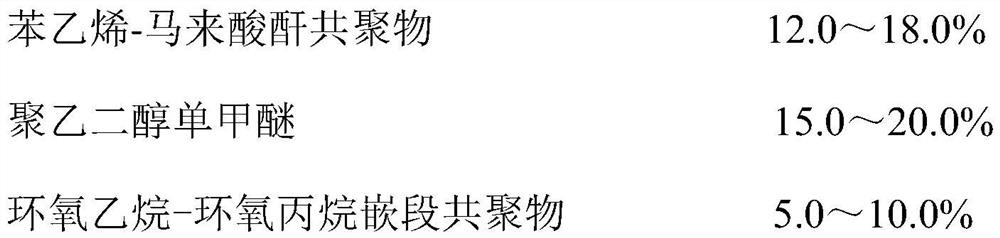

[0037] A kind of hyperbranched polymer aqueous dispersant, its preparation steps are as follows:

[0038] According to weight percentage, weigh 125.0 parts of SMA1200, 155.0 parts of MPEG1000, 65.0 parts of EO-PO-EO block copolymer into the reaction kettle, heat up to 120°C and start to melt, turn on the vacuum, and control the vacuum degree to 0.09MPa for dehydration 1h; start stirring after complete melting, continue to raise the temperature to 170-175°C, and control the vacuum degree to 0.07-0.08MPa to react for 4h, take samples every 0.5h to detect the acid value, stop the reaction when the acid value reaches the specified value; cool down to 120°C, turn off N 2, add 2.6 parts of triethylamine under stirring, and add 520.0 parts of deionized water at the same time, when the pH value is 7.5 to 7.8, cool down to 60 ° C, filter and pack, and obtain a hyperbranched polymer aqueous dispersant with a solid content of 40.6%.

Embodiment 2

[0040] A kind of hyperbranched polymer aqueous dispersant, its preparation steps are as follows:

[0041] According to the percentage by weight, weigh 126.0 parts of SMA1000, 165.0 parts of MPEG1000, 55.0 parts of EO-PO-EO block copolymer into the reactor, heat up to 120°C and start to melt, turn on the vacuum, and control the vacuum to 0.09MPa for dehydration 1h; start stirring after complete melting, continue to heat up to 170-172°C, and control the vacuum degree to 0.07-0.08MPa to react for 4h, take samples every 0.5h to detect the acid value, stop the reaction when the acid value reaches the specified value; cool down to 120°C, turn off N 2 , add 2.8 parts of triethylamine under stirring, and add 500.0 parts of deionized water at the same time, when the pH value is 7.0 to 7.2, cool down to 60 ° C, filter and pack, and obtain a hyperbranched polymer aqueous dispersion with a solid content of 41.5%.

Embodiment 3

[0043] A kind of hyperbranched polymer aqueous dispersant, its preparation steps are as follows:

[0044] According to weight percentage, weigh 125.0 parts of SMA1000, 160.0 parts of MPEG1200, 60.0 parts of EO-PO-EO block copolymer into the reactor, heat up to 120°C and start to melt, turn on the vacuum, and control the vacuum to 0.09MPa for dehydration 1h; start stirring after complete melting, continue to heat up to 170-172°C, and control the vacuum degree to 0.07-0.08MPa to react for 4h, take samples every 0.5h to detect the acid value, stop the reaction when the acid value reaches the specified value; cool down to 120°C, turn off N 2 , add 3.0 parts of triethanolamine under stirring, and add 500.0 parts of deionized water at the same time, when the pH value is 7.2 to 7.5, cool down to 60 ° C, filter and pack, and obtain a hyperbranched polymer aqueous dispersion with a solid content of 41.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com