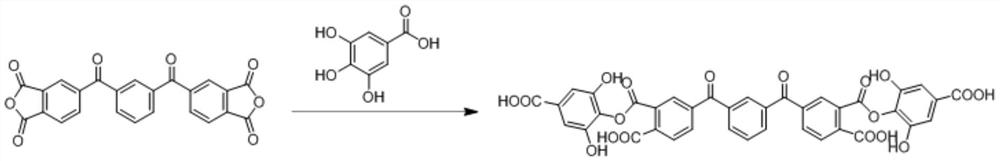

Preparation method of ketone anhydride-polyphenolic acid active oxygen molecule finishing agent

A technology of polyphenolic acid and active oxygen, applied in the field of textile processing, can solve the problems of high activity and poor stability of active oxygen components, and achieve efficient killing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

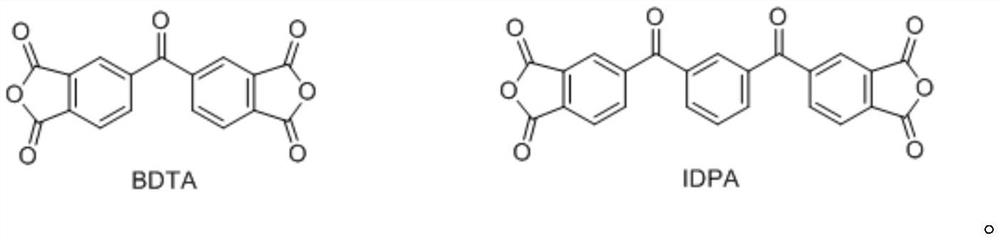

[0025] 1. Synthesis of active oxygen molecules of ketone anhydride-polyphenolic acid:

[0026] Add 0.05mol BDTA to THF, add 0.05g DMAP after complete dissolution, then dropwise add 0.1mol caffeic acid THF solution, heat to reflux state, keep it warm for 5 hours, and when the reaction is complete, add water and ethyl acetate at a volume ratio of 1:1 Ester extraction, take the organic layer, distill under reduced pressure to recover ethyl acetate, vacuum dry, and column chromatography to obtain BDTA-caffeic acid compound. 1 H NMR(DMSO-d6,400MHz),δ:13.22(s,2H),12.05(s,2H),9.46(s,2H),8.41-8.21(m,6H),7.45(d,2H),7.28 -7.26(m,6H), 6.28(d,2H); ESI-MS: m / z=683.1[M+1] + .

[0027]

[0028] 2. Preparation of ketone anhydride-polyphenolic acid reactive oxygen molecule finishing agent:

[0029] Add ketone anhydride-polyphenolic acid active oxygen molecules to the mixed solvent of ethanol and water with a volume ratio of 2:1, the mass concentration of the ketone anhydride-polyphenolic...

Embodiment 2

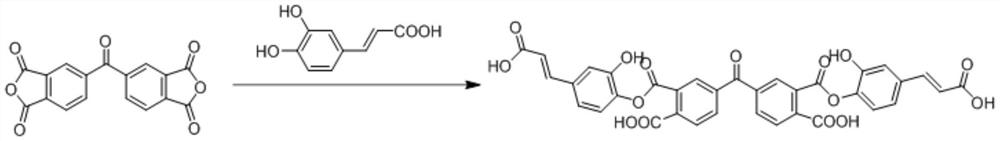

[0031] 1. Synthesis of active oxygen molecules of ketone anhydride-polyphenolic acid:

[0032] Add 0.05mol IDPA to tetrahydrofuran, add 0.08g DMAP after the dissolution is complete, then add dropwise 0.1mol gallic acid tetrahydrofuran solution, heat to reflux state and keep it warm for 5 hours. After the reaction is completed, add water and ethyl acetate with a volume ratio of 1:1 Ester extraction, take the organic layer, distill under reduced pressure to recover ethyl acetate, vacuum dry, and column chromatography to obtain IDPA-gallic acid compound. 1 H NMR(DMSO-d6,400MHz),δ:13.20(s,2H),12.75(s,2H),9.47(s,4H),8.40-8.22(m,6H),7.54-7.47(m,4H) ,7.15(s,4H); ESI-MS: m / z=767.08[M+1] + .

[0033]

[0034] 2. Preparation of ketone anhydride-polyphenolic acid reactive oxygen molecule finishing agent:

[0035] Add ketone anhydride-polyphenolic acid active oxygen molecules to a mixed solvent of acetone and water with a volume ratio of 1:1, the mass concentration of ketone anhydri...

Embodiment 3

[0037] 1. Synthesis of active oxygen molecules of ketone anhydride-polyphenolic acid:

[0038] Add 0.05mol BDTA to tetrahydrofuran, add 0.05g DMAP after complete dissolution, then dropwise add 0.1mol chlorogenic acid tetrahydrofuran solution, heat to reflux state and keep it warm for 5 hours. After the reaction is completed, add water and acetic acid with a volume ratio of 1:1 Extract with ethyl ester, take the organic layer, distill under reduced pressure to recover ethyl acetate, dry in vacuum, and perform column chromatography to obtain BDTA-chlorogenic acid compound. 1 H NMR(DMSO-d6,400MHz),δ:13.22(s,2H),12.85(s,2H),9.46(s,2H),8.41-8.21(m,6H),7.45(d,2H),7.28 -7.26(m,6H),6.31(d,2H),5.91(s,2H),4.62-4.61(m,4H),4.39(s,2H),4.12(m,2H),3.54(m,2H ),1.94-1.85(m,8H); ESI-MS: m / z=1031.2[M+1] + .

[0039]

[0040] 2. Preparation of ketone anhydride-polyphenolic acid reactive oxygen molecule finishing agent:

[0041]Add ketone anhydride-polyphenolic acid active oxygen molecules ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| control rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com