Method for treating nitrobenzene wastewater by ultraviolet light-reinforced Fenton oxidation

A technology for nitrobenzene wastewater and oxidation treatment, which is applied in the fields of oxidized water/sewage treatment, chemical instruments and methods, special compound water treatment, etc., can solve the problems of poor nitrobenzene wastewater treatment effect, etc. Environmental benefits, ease of implementation, effects of process solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

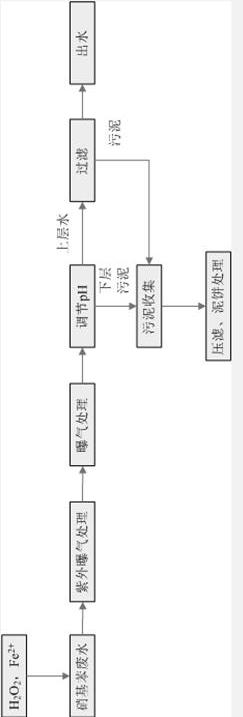

Image

Examples

Embodiment 1

[0040] Pour 500ml of nitrobenzene wastewater into a glass container and add H 2 o 2 solution and Fe 2+ The mixed reagent, in the mixed reagent H 2 o 2 with Fe 2+ The molar ratio is 1:4. The mass concentration of hydrogen peroxide in the waste water was 0.1%. After mixing evenly, the pH value of the mixed solution was adjusted to 2.2 with sulfuric acid. Send the above mixed solution into the self-made ultraviolet light oxidation treatment device, adjust the wavelength to 315nm, make it treated in ultraviolet light for 20min, and at the same time carry out aeration treatment on the wastewater; aerate the mixed solution treated by ultraviolet light for 0.5h The pH value of the treated mixed solution is adjusted with NaOH solution to be 8.0, and the upper layer liquid and the lower layer sludge are separated by standing, and the sludge is sent to the sludge collection tank; the upper layer liquid is filtered to obtain qualified process effluent; After the sludge is collected...

Embodiment 2

[0042] Pour 500ml of nitrobenzene wastewater into a glass container and add H 2 o 2 solution and Fe 2+ The mixed reagent, in the mixed reagent H 2 o 2 with Fe 2+The molar ratio is 1:2. The mass concentration of hydrogen peroxide in the wastewater is 0.2%. After mixing evenly, adjust the pH value of the mixed solution to 2.5 with sulfuric acid. Send the above mixed solution into the self-made ultraviolet light oxidation treatment device, adjust the wavelength to 345nm, make it treated in ultraviolet light for 25min, and at the same time carry out aeration treatment on the wastewater; aerate the mixed solution treated by ultraviolet light for 0.8h The pH value of the treated mixed solution is adjusted with NaOH solution to be 8.2, and the upper layer liquid and the lower layer sludge are separated by standing, and the sludge is sent to the sludge collection tank; the upper layer liquid is filtered to obtain the qualified process effluent; After the sludge is collected, the...

Embodiment 3

[0044] Pour 500ml of nitrobenzene wastewater into a glass container and add H 2 o 2 solution and Fe 2+ The mixed reagent, in the mixed reagent H 2 o 2 with Fe 2+ The molar ratio is 1:1. The mass concentration of hydrogen peroxide in the waste water is 0.5%. After mixing evenly, the pH value of the mixed solution is adjusted to 2.5 with hydrochloric acid. Send the above mixed solution into the self-made ultraviolet light oxidation treatment device, adjust the wavelength to 350nm, make it treated in ultraviolet light for 30min, and aerate the wastewater at the same time; aerate the mixed solution treated by ultraviolet light for 1.0h The pH value of the treated mixed solution is adjusted with NaOH solution to be 8.2, and the upper layer liquid and the lower layer sludge are separated by standing, and the sludge is sent to the sludge collection tank; the upper layer liquid is filtered to obtain the qualified process effluent; After the sludge is collected, the sludge is pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com