Compound furnace profile circulating fluidized bed boiler

A circulating fluidized bed and boiler technology, which is applied to fluidized bed combustion equipment, steam boilers, combustion types, etc., can solve the problems of local wear, difficult maintenance, and easy vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

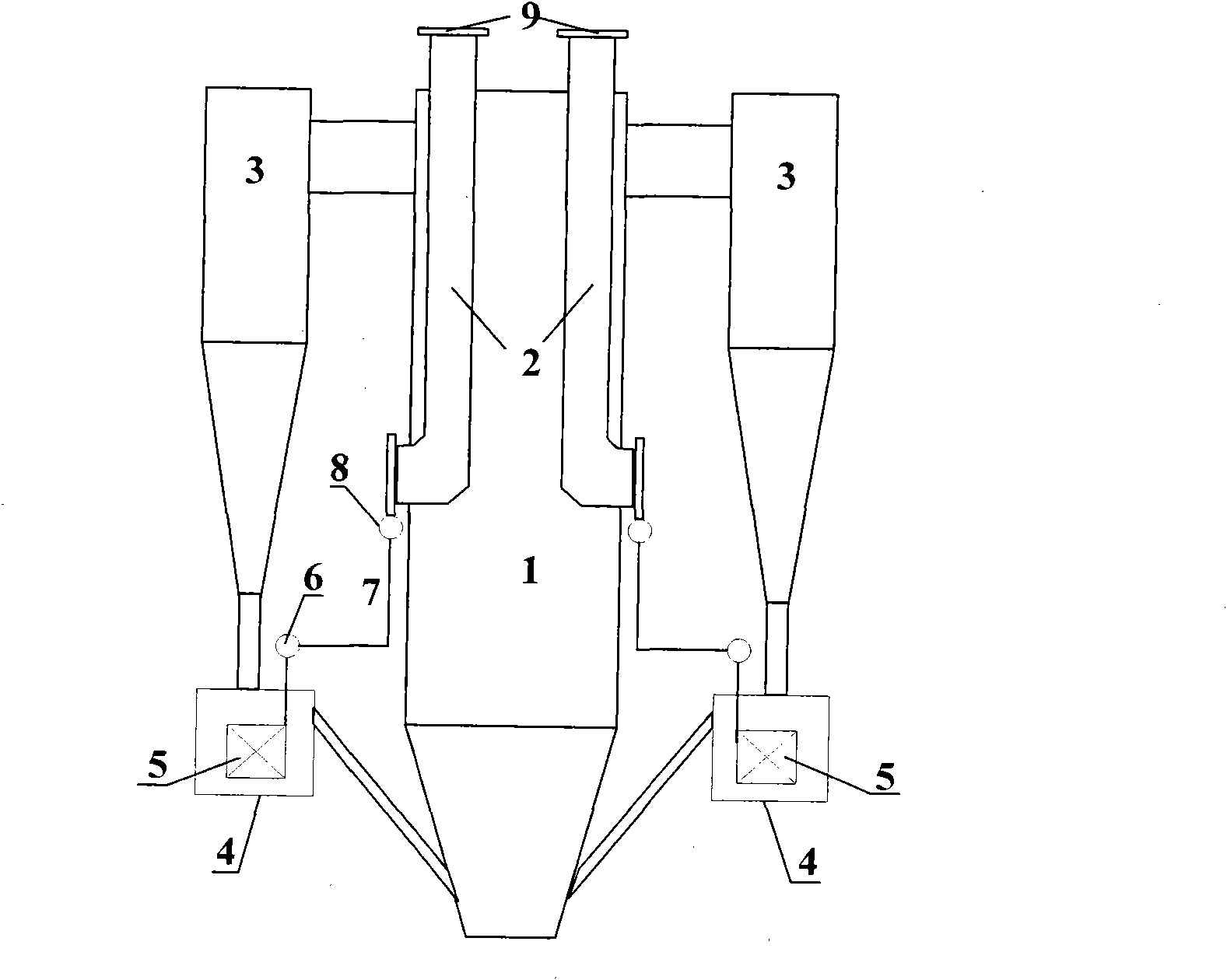

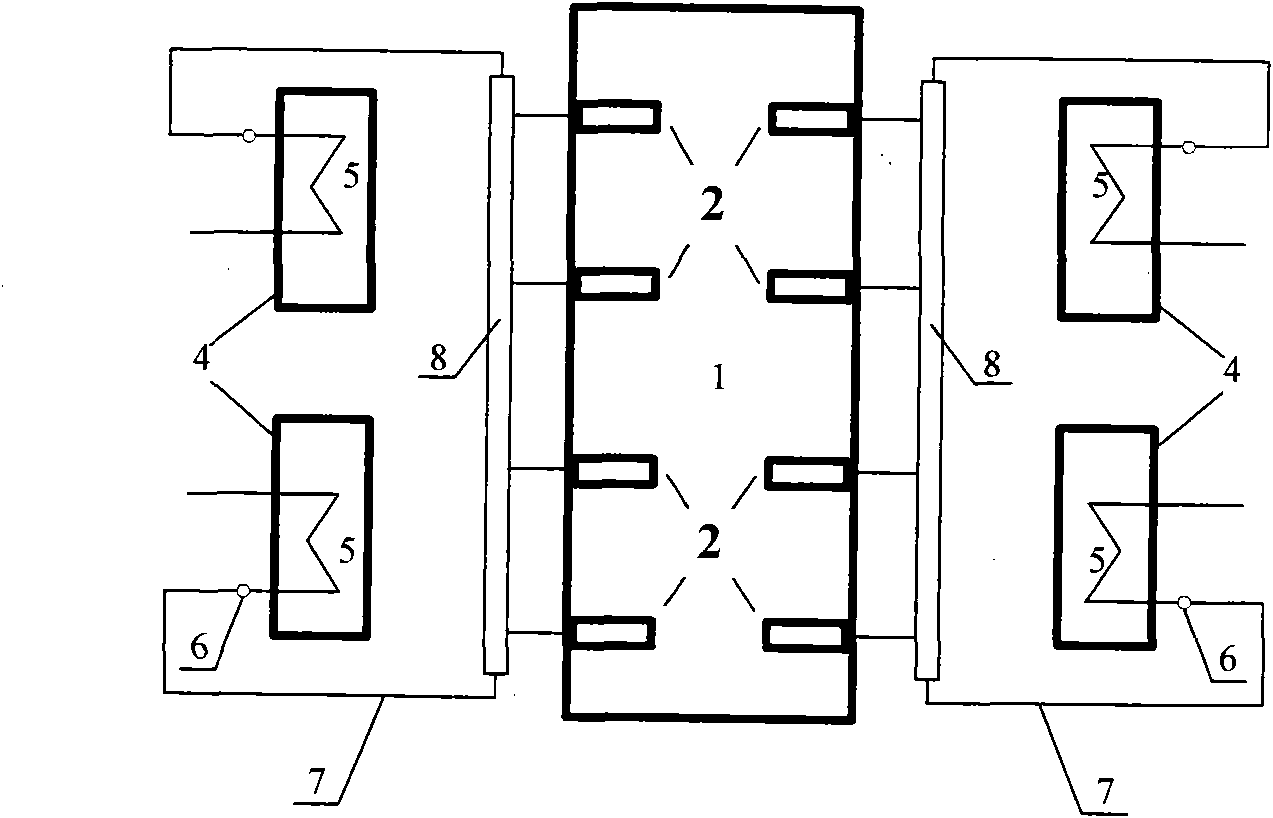

[0024] Embodiment one, such as figure 1 , figure 2 As shown, the overall layout of the boiler is as follows: four separators 3 are arranged on both sides of the furnace 1, and a panel heating surface 2 is arranged in the furnace 1, and the panel heating surface 2 is arranged in parallel with the front and rear walls of the furnace 1. The boiler has four heat exchangers 4 in total. The heat exchanger 4 is arranged with a heat exchanger heating surface 5. Part of the high-temperature ash particles separated by the cyclone separator 3 are heated by the heat exchanger after being fluidized by air in the heat exchanger 4. The surface 5 is sent back to the furnace 1 after heat exchange, while the other part of the high-temperature ash particles is directly returned to the furnace 1. The lower header 8 of the panel heating surface and the header 6 of the heat exchanger heating surface are connected through the pipe 7, and the panel heating surface 2 and the heating surface 5 of the...

Embodiment 2

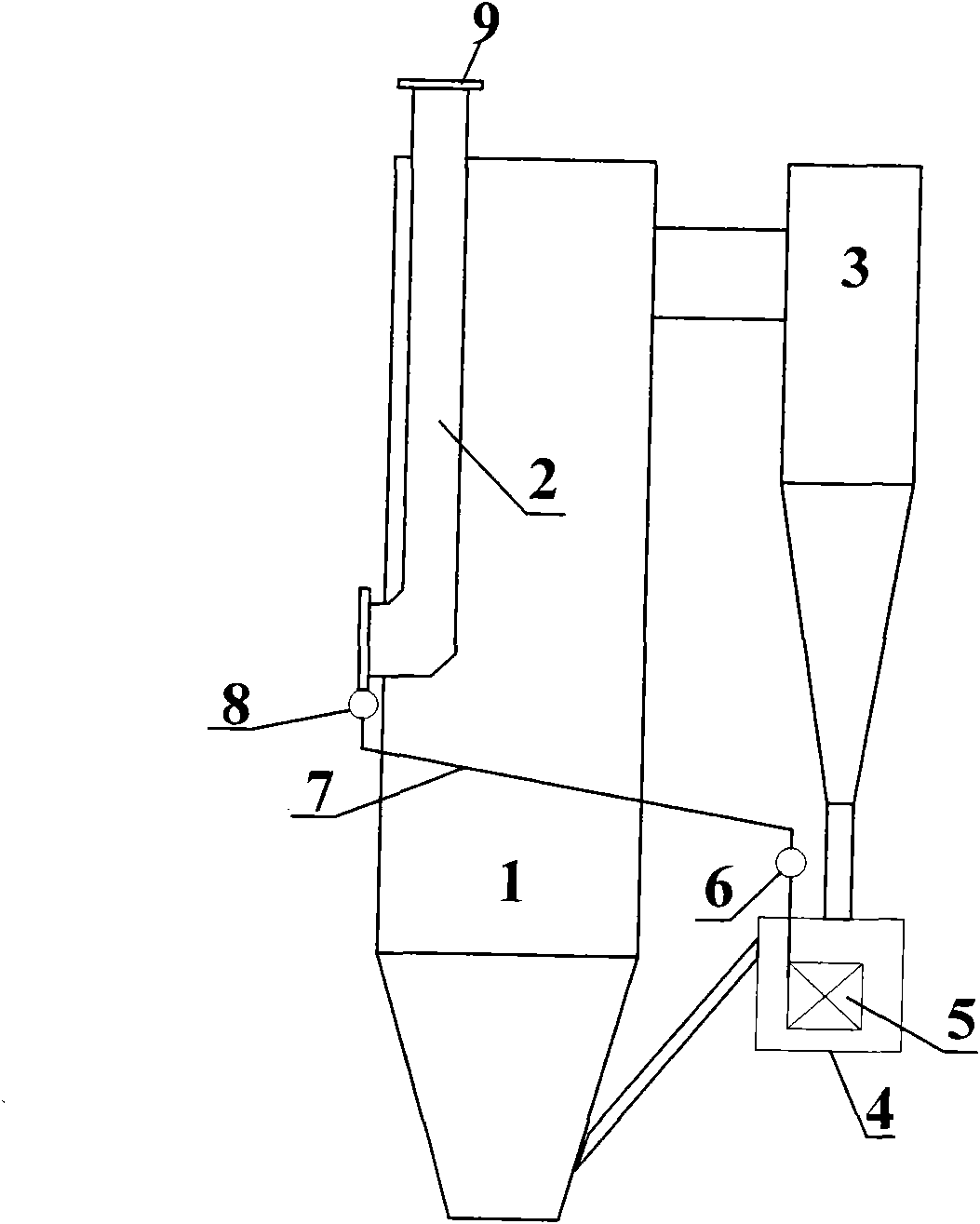

[0025] Embodiment two, such as image 3 , Figure 4 As shown, the overall layout of the boiler is that two separators 3 are arranged on the rear side of the furnace 1, and a panel heating surface 2 is arranged inside the furnace 1, and the panel heating surface 2 is arranged perpendicular to the front wall of the furnace 1. The boiler has two heat exchangers 4 in total. The heat exchanger 4 is equipped with a heat exchanger heating surface 5. Part of the high-temperature ash particles separated by the cyclone separator 3 are heated by the heat exchanger after being fluidized by air in the heat exchanger 4. The surface 5 is sent back to the furnace 1 after heat exchange, while the other part of the high-temperature ash particles is directly returned to the furnace. The lower header 8 of the panel heating surface and the header 6 of the heat exchanger heating surface are connected through the pipe 7, and the panel heating surface 2 and the heating surface 5 of the heat exchange...

Embodiment 3

[0026] Embodiment three, such as Figure 5 , Figure 6 As shown, the overall layout of the boiler is that four separators 3 are arranged on both sides of the furnace 1, and there are four heat exchangers 4 in total. The heat receiving surfaces 5 of the heat exchangers arranged in the two heat exchangers 4 on the left side of the furnace 1 are For the high-temperature reheater, the heating surface 5 of the heat exchanger arranged in the two heat exchangers 4 on the right side of the furnace 1 is a low-temperature superheater. The steam from the superheater of the flue at the tail of the boiler flows into the heat exchanger heating surface 5 (low temperature superheater) in the heat exchanger 4 arranged on the left side of the furnace, and part of the high temperature ash particles separated by the cyclone separator 3, After the air is fluidized in the heat exchanger 4, it exchanges heat with the heat receiving surface 5 (low-temperature superheater) of the heat exchanger and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com