An automatic grinding machine for mold surface processing

A surface processing and mold technology, applied in the field of automatic grinding machines, can solve the problems of damage to mold processing quality, adhesion, etc., and achieve the effects of ensuring smoothness, fast drying, and grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

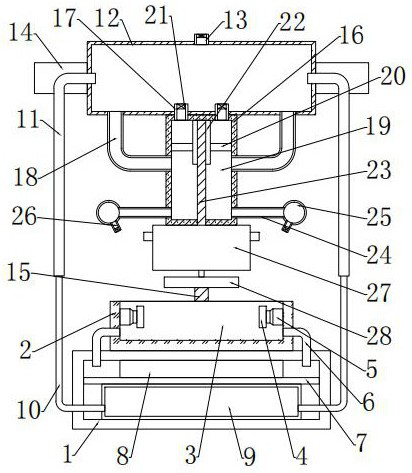

[0032] seefigure 1 , in an embodiment of the present invention, an automatic grinding machine for mold surface processing includes a base 1, a support mechanism is provided on the outside of the base 1, and the support mechanism is connected to a water storage mechanism provided on the inside of the base 1 A grinding mechanism is provided on the outside of the support mechanism, and a connection mechanism for cooperating with the grinding mechanism to complete water spray is arranged between the grinding mechanism and the support mechanism, and the connection mechanism is fixedly connected with the support mechanism, so A clamping mechanism for fixing the mold is provided between the grinding mechanism and the base 1 , and the clamping mechanism is fixedly connected with the base 1 .

Embodiment 2

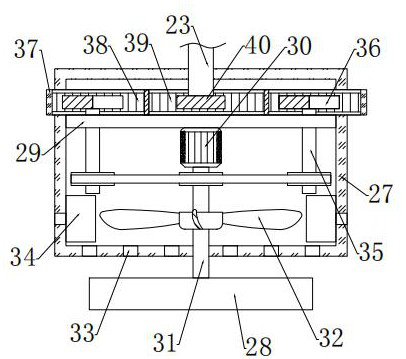

[0034] For an example of the invention, see figure 1 with image 3 , the support mechanism includes a connection box 12 arranged on the outside of the base 1, a support plate 14 is fixedly connected to the outside of the connection box 12, and a threaded rod 15 is provided on the inside of the support plate 14, and the threaded rod 15 is driven by the second motor 41, the second motor 41 is fixedly connected and arranged on the outside of the base 1, the two sides of the connection box 12 are fixedly connected with movable pipes 11, and the inner side of the movable pipe 11 is slidably connected with Water delivery pipe 10, the other end of the water delivery pipe 10 is connected to the water storage mechanism arranged inside the base 1, and the lifting of the support plate 14 can be realized by setting the support mechanism and using the second motor 41 to drive the threaded rod 15 , the support plate 14 can drive the connection box 12 to move, and then realize the lifting o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com