Production process of stainless steel water meter shell

A technology of production process and production process, which is applied in the field of water meter shell processing and manufacturing, can solve the problems of high labor intensity, low product qualification rate, and high energy consumption, so as to improve the safety of use, reduce the degree of air pollution, and avoid serious pollution The effect of air environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

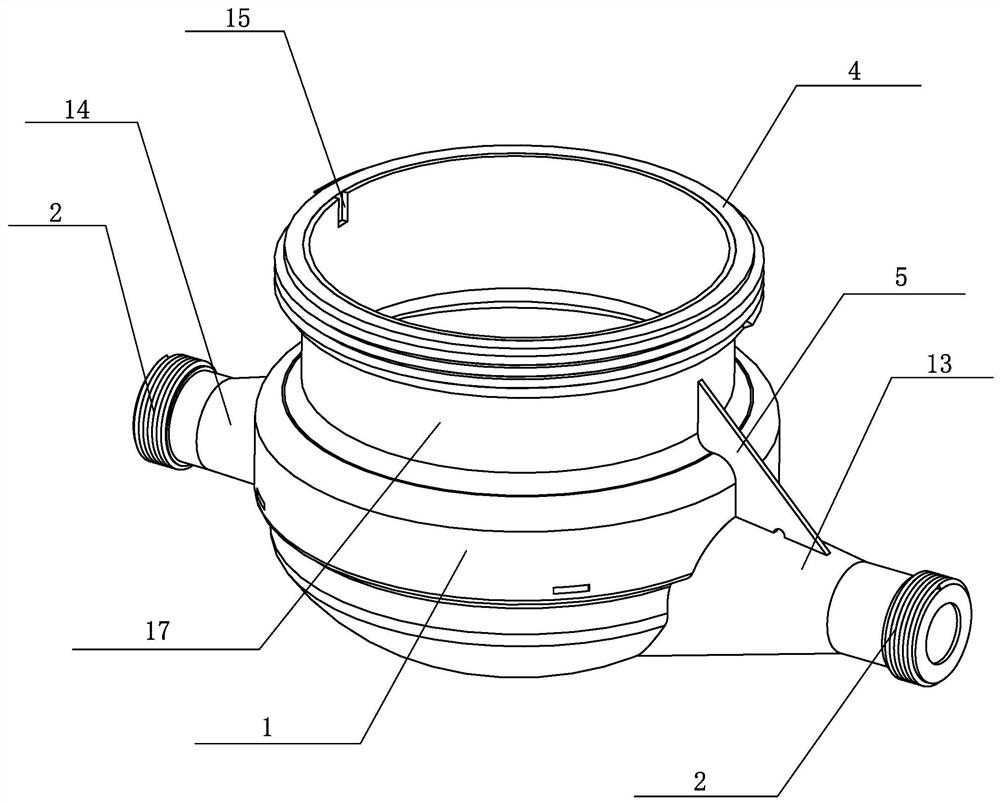

[0034] Below will combine specific embodiment and appended Figure 1-3 , clearly and completely describe the technical solutions in the embodiments of the present invention, obviously, the described embodiments are only some preferred embodiments of the present invention, not all the embodiments. Those skilled in the art can make similar modifications without departing from the connotation of the present invention, so the present invention is not limited by the specific embodiments disclosed below.

[0035] When utilizing the present invention to process and manufacture stainless steel water watch cases, it is necessary to purchase corresponding stainless steel pipes and stainless steel plate raw materials at first, so that the production and manufacture of stainless steel water watch cases can be successfully realized by using this process.

[0036] The invention provides a production process of a stainless steel water watch case, comprising the following steps:

[0037] S1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com