Automatic cleaning device and method for high-voltage transmission line insulator

A high-voltage transmission line, automatic cleaning technology, applied in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., can solve the problems of unsuitable insulator cleaning work, cumbersome operation, inapplicability, etc., and achieve industrial application. The effect of high value, improved cleaning efficiency, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The application will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present application.

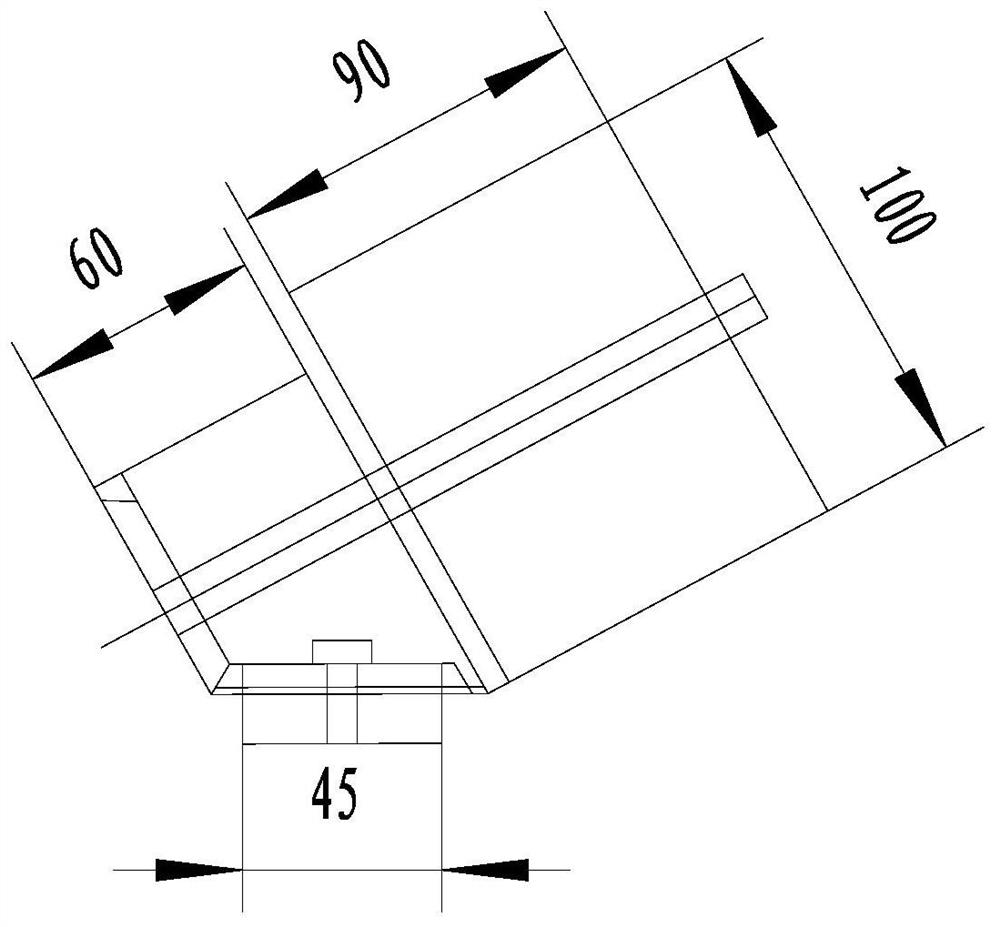

[0048] Such as figure 1 , an automatic cleaning device for high-voltage transmission line insulators, including an insulating brush head 1, a main insulating rod 2, a rotating connecting shaft 3, a bevel gear 4, an electric wrench 5, and a multi-connection joint 6.

[0049] The insulating brush head 1 is fixed on the top of the main insulating rod 2, and the electric wrench 5 is fixed on the bottom of the main insulating rod 2. The main insulating rod 2 is a multi-section type, which can be lengthened 6 by a multi-joint connector.

[0050] The main insulating rod 2 is hollow inside and runs through the rotating connection shaft 3; the rotating connecting shaft 3 can be lengthened through the conca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com