Application and preparation method of hydrogel bead material

A hydraulic coagulation and application technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve problems such as difficult to realize large-scale industrialization, impossible to realize resource recycling, impossible to realize the separation of fluorine and uranium, and achieve excellent Adsorption effect, easy control of the production process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is illustrated below in conjunction with examples.

[0031] One, the preparation of material of the present invention

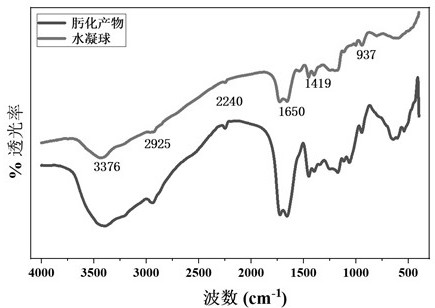

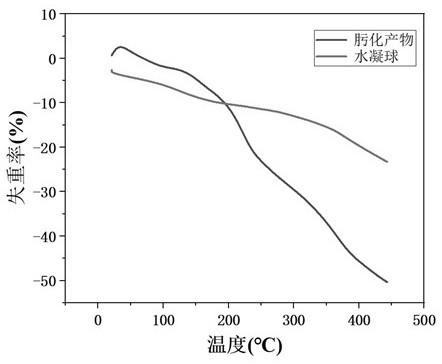

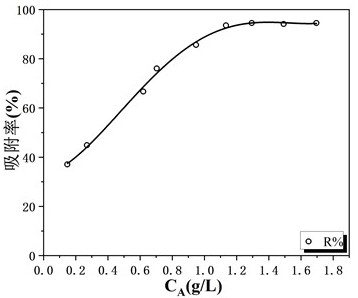

[0032] 1) The preparation method of the oximated acrylic acid / acrylonitrile of the present invention that can enrich and separate uranium-attached materials is as follows: take 8.28 g of acrylic acid and 5.3 g of acrylonitrile in a 250.00 mL three-necked flask, mix them uniformly and add 80 mL to remove Ionized water, stirred and heated to 50°C, and 0.8 g of tetramethylethylenediamine (TEMED) was added as a cross-linking agent. Take 20 mL of potassium persulfate (KPS) solution and add it to the above-mentioned three-necked flask, mix well and then raise the temperature to 70 ℃ ~ 75 ℃, condense and reflux to fully react to obtain the desired product, filter under reduced pressure, wash with deionized water, and freeze-dry Obtain acrylic acid and acrylonitrile polymerization cross-linked product. Prepare 150.00 mL of methanol aque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com