Preparation method of micro-arc oxidation black film layer doped with rare earth salt and graphene

A micro-arc oxidation and black film technology, applied in anodizing, coating, surface reaction electrolytic coating, etc., can solve the problems of weak adhesion between the black ceramic film and the substrate, low hardness of the coating, easy fading, etc. Achieve the effect of changing electrical conductivity, increasing corrosion potential, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

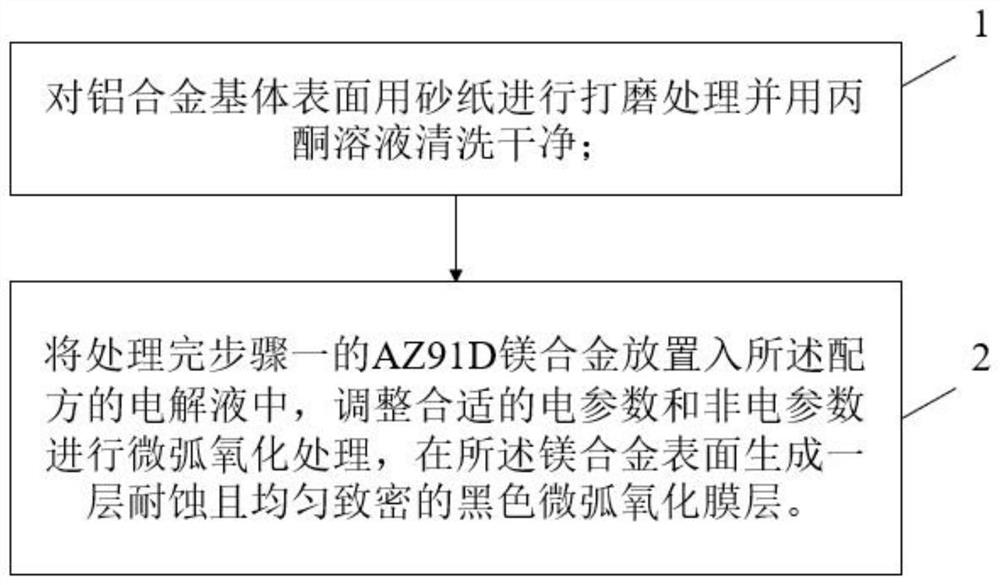

[0021] Such as figure 1 As shown, in this embodiment, a corrosion-resistant, dense and uniform black micro-arc oxidation film is formed in situ on the magnesium alloy base metal.

[0022] In this embodiment, the material of the metal base is AZ91D magnesium alloy.

[0023] In this embodiment, the components that improve the surface corrosion resistance of the AZ91D magnesium alloy are MgO and Mg with a spinel structure 2 SiO 4 , the material that appears black on the surface is MnO 2 .

[0024] In this embodiment, the thickness of the black micro-arc oxidation film is 0-20 μm.

[0025] combine figure 1 , a preparation method of a black micro-arc oxidation film layer, comprising the following steps:

[0026] Step 1: Use 200#, 400#, 600#, 800#, 1000# sandpaper to polish the AZ91D magnesium alloy with a sample size of 50mm×50mm×2mm, so that the surface of the magnesium alloy is smooth and the direction of the scratches appears to be consistent. Clean the surface with aceto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com