Foam scrubbing agent as well as preparation method and application thereof

A technology of foaming agent and active agent, which is applied in chemical instruments and methods, earth drilling and mining fluids, etc. It can solve the problems of poor foam stability, limited improvement range, and difficult secondary foaming, so as to improve the diffusion effect, The effect of wide source of raw materials and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

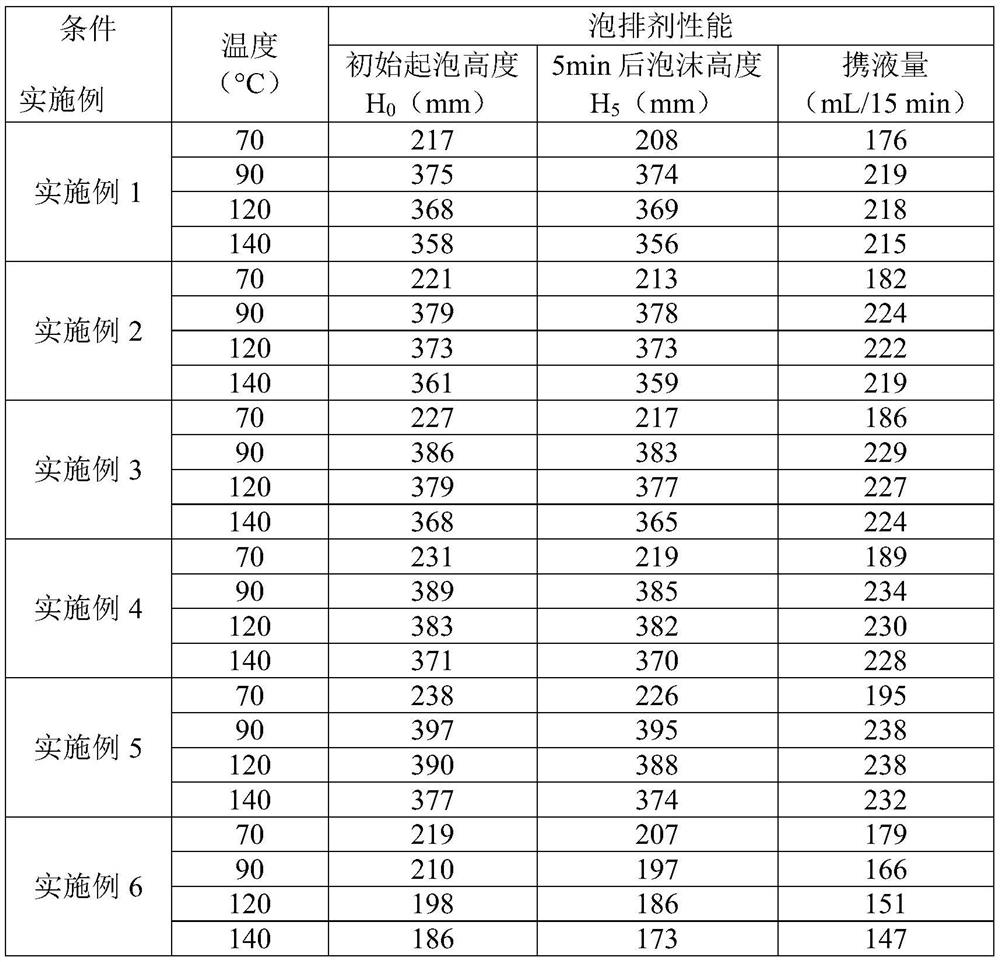

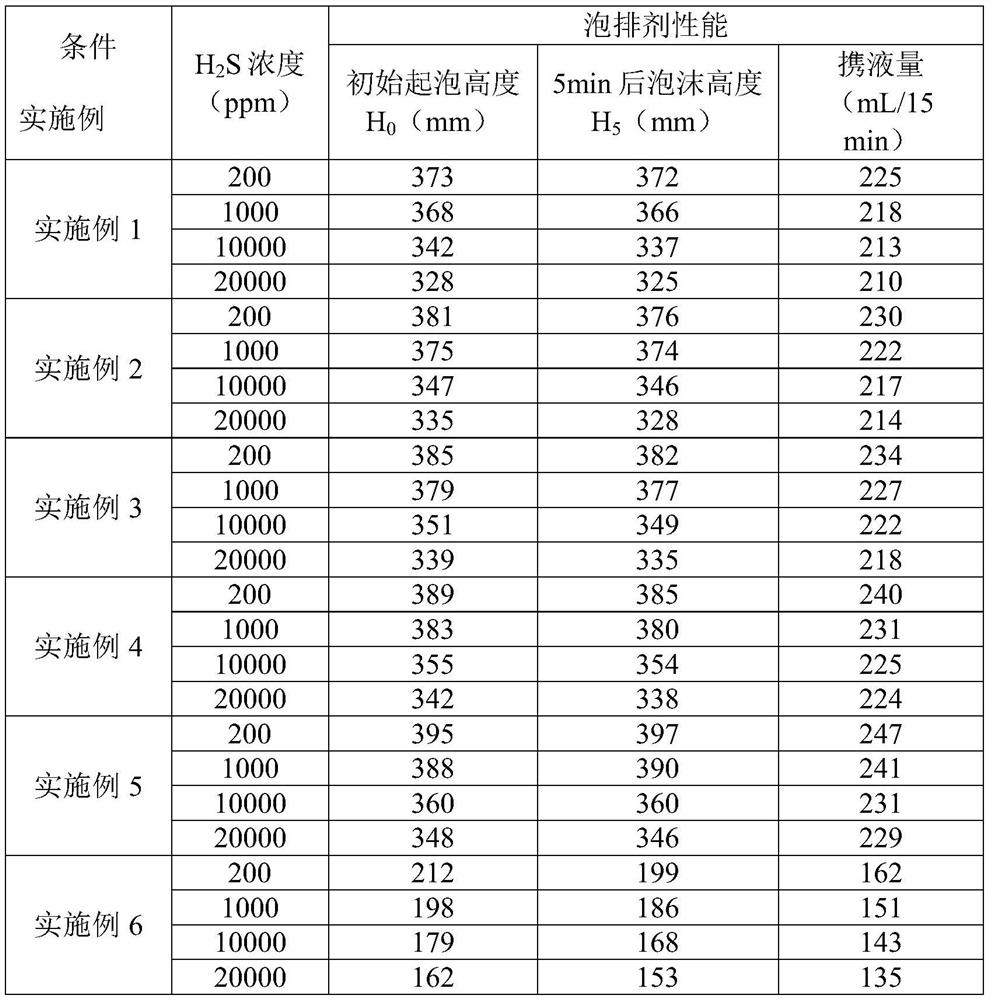

Examples

Embodiment 1

[0037] Octaramidopropyl Betaine: 10%, Myristyl Dimethyl Betaine: 8%, Alkyl Polyglycoside APG-0810: 5%, Sodium Dodecylbenzene Sulfonate: 0.1%, Fatty Alcohol Sodium polyoxyethylene ether sulfate: 0.1%, ammonium chloride: 5%, sodium nitrite: 6.5%, make up 100% with water. Its preparation method is as follows:

[0038] A. According to the formula ratio, slowly add octadecylamidopropyl betaine and myristyl dimethyl betaine into the stainless steel reaction kettle, and stir at a low speed at 20°C for 10 minutes;

[0039] B. Slowly add alkyl polyglycoside APG-0810 to the above mixed solution, then add deionized water, heat the mixed solution to 40°C, and continue to stir at a low speed for 20 minutes;

[0040] C. Slowly add sodium dodecylbenzenesulfonate to the above mixed solution, and continue to stir the mixed solution at a low speed for 20 minutes at 40°C;

[0041] D. Heat the above solution to 60°C, add fatty alcohol polyoxyethylene ether sodium sulfate at one time, and stir a...

Embodiment 2

[0044]Octaramidopropyl Betaine: 13%, Myristyl Dimethyl Betaine: 10%, Alkyl Polyglycoside APG-0810: 6%, Sodium Dodecylbenzene Sulfonate: 0.6%, Fatty Alcohol Sodium polyoxyethylene ether sulfate: 0.2%, ammonium chloride: 6%, sodium nitrite: 7.3%, make up 100% with water. Its preparation method is as follows:

[0045] A. According to the formula ratio, slowly add octadecylamidopropyl betaine and myristyl dimethyl betaine into the stainless steel reaction kettle, and stir at a low speed of 25°C for 12 minutes;

[0046] B. Slowly add alkyl polyglycoside APG-0810 to the above mixed solution, then add deionized water, heat the mixed solution to 42°C, and continue to stir at a low speed for 22 minutes;

[0047] C. Slowly add sodium dodecylbenzenesulfonate to the above mixed solution, and continue to stir the mixed solution at a low speed for 22 minutes at 42°C;

[0048] D. Raise the temperature of the above solution to 62°C, add fatty alcohol polyoxyethylene ether sodium sulfate at ...

Embodiment 3

[0051] Octaramidopropyl Betaine: 15%, Myristyl Dimethyl Betaine: 13%, Alkyl Polyglycoside APG-0810: 7.5%, Sodium Dodecylbenzene Sulfonate: 0.9%, Fatty Alcohol Sodium polyoxyethylene ether sulfate: 0.25%, ammonium chloride: 6.5%, sodium nitrite: 8.1%, make up 100% with water. Its preparation method is as follows:

[0052] A. Slowly add octadecylamidopropyl betaine and myristyl dimethyl betaine into the stainless steel reaction kettle according to the formula ratio, and stir at a low speed of 30°C for 15 minutes;

[0053] B. Slowly add alkyl polyglycoside APG-0810 to the above mixed solution, then add deionized water, heat the mixed solution to 45°C, and continue to stir at a low speed for 25 minutes;

[0054] C. Slowly add sodium dodecylbenzenesulfonate to the above mixed solution, and continue to stir the mixed solution at a low speed for 25 minutes at 45°C;

[0055] D. Heat the above solution to 65°C, add fatty alcohol polyoxyethylene ether sodium sulfate at one time, and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com