Composite dust suppressant as well as preparation method and application thereof

A technology of dust suppressant and chelating agent, which is applied in the field of composite dust suppressant and its preparation, which can solve the problem that dust suppressant cannot meet the requirements of use, dust suppressant is difficult to achieve dust suppression effect, strong hydrophobicity is not easy to be wetted by water, etc. Problems, to achieve the effect of not easy to lose quickly, improve viscosity, and reduce water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides the preparation method of the preparation method of the composite dust suppressant described in the above scheme, comprising the following steps:

[0033] Mix halides, strong electrolytes, non-cationic water-soluble polymers, non-cationic surfactants, chelating agents, water and NaOH to obtain a mixed solution, mix the mixed solution with residual oil and disperse to obtain a residual oil emulsion ;

[0034] The gelatinized starch and residual oil emulsion are mixed to obtain a composite dust suppressant.

[0035] In the present invention, halides, strong electrolytes, non-cationic water-soluble polymers, non-cationic surfactants, chelating agents, water and NaOH are mixed to obtain a mixed liquid. In the present invention, the mixing temperature is preferably 70 to 75°C, more preferably 75°C. In the present invention, after heating the water to the mixing temperature, the halides, strong electrolytes, non-cationic water-soluble pol...

Embodiment 1

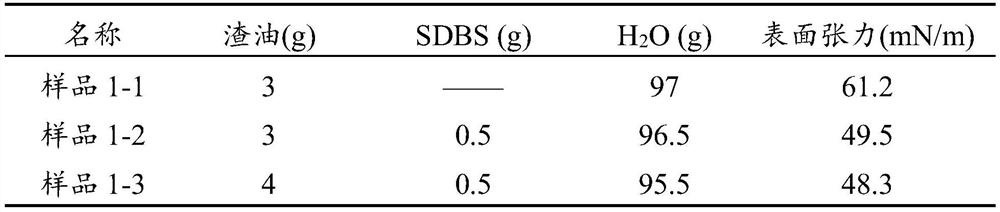

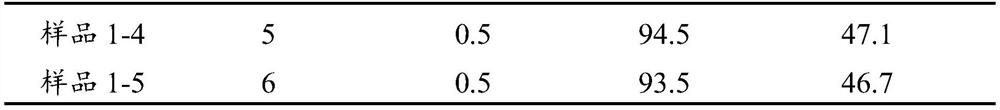

[0043] According to Table 1, the residue oil, SDBS and water of corresponding quality were weighed and mixed uniformly at 75° C. to obtain residue oil emulsion samples 1-1 to 1-5 in sequence. Use the JZYW-200B micro-controlled automatic interfacial tensiometer to measure the surface tension of all samples, measure each sample three times, read the three measurement values, add the three measurement values and take the average value, and the average value is the final value of the sample surface tension value. See Table 1 for the surface tension of samples 1-1 to 1-5.

[0044] Table 1 Surface tension of residual oil emulsion

[0045]

[0046]

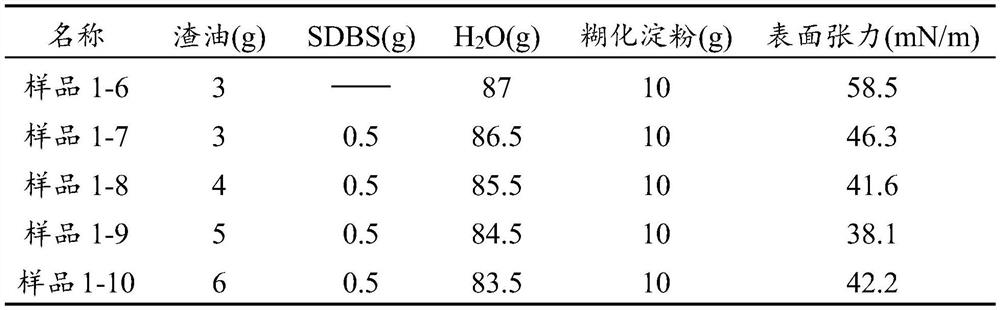

[0047] As shown in Table 2, weigh the residual oil, SDBS, water and gelatinized starch of corresponding quality, mix them evenly at 75°C, and obtain samples 1-6 to 1-10 in sequence. Use the JZYW-200B micro-controlled automatic interfacial tensiometer to measure the surface tension of all samples, measure each sample three times...

Embodiment 2

[0056]As shown in Table 4, the components with corresponding masses were weighed and mixed uniformly at 70° C. to obtain samples 2-1 to 2-4 in sequence. Weigh the plastic cup containing 100g sample on an analytical balance, then place the plastic cup in a ventilated place with a window to dry for 10 hours at a temperature of 23-28°C, after 10 hours, weigh the dried sample on an analytical balance. The water evaporation was calculated by the quality difference of the samples before and after drying. According to the amount of water evaporation, the anti-evaporation performance of various hygroscopic materials is compared. See Table 4 for the water evaporation of samples 2-1 to 2-4.

[0057] The water evaporation of table 4 residual oil emulsion

[0058]

[0059] As shown in Table 5, the components with corresponding masses were weighed and mixed uniformly at 70° C. to obtain samples 2-5 to 2-8 in sequence. Weigh the plastic cup containing 100g sample on an analytical bala...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com