Method for removing ammonia nitrogen in water through TiO2-NTs/Sb-SnO2/PbO2 electrocatalytic oxidation and application of method

An electrocatalytic oxidation and water removal technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., can solve the problems of different technical difficulties and large differences, avoid accumulation and improve stability The effect of reducing the content of total nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

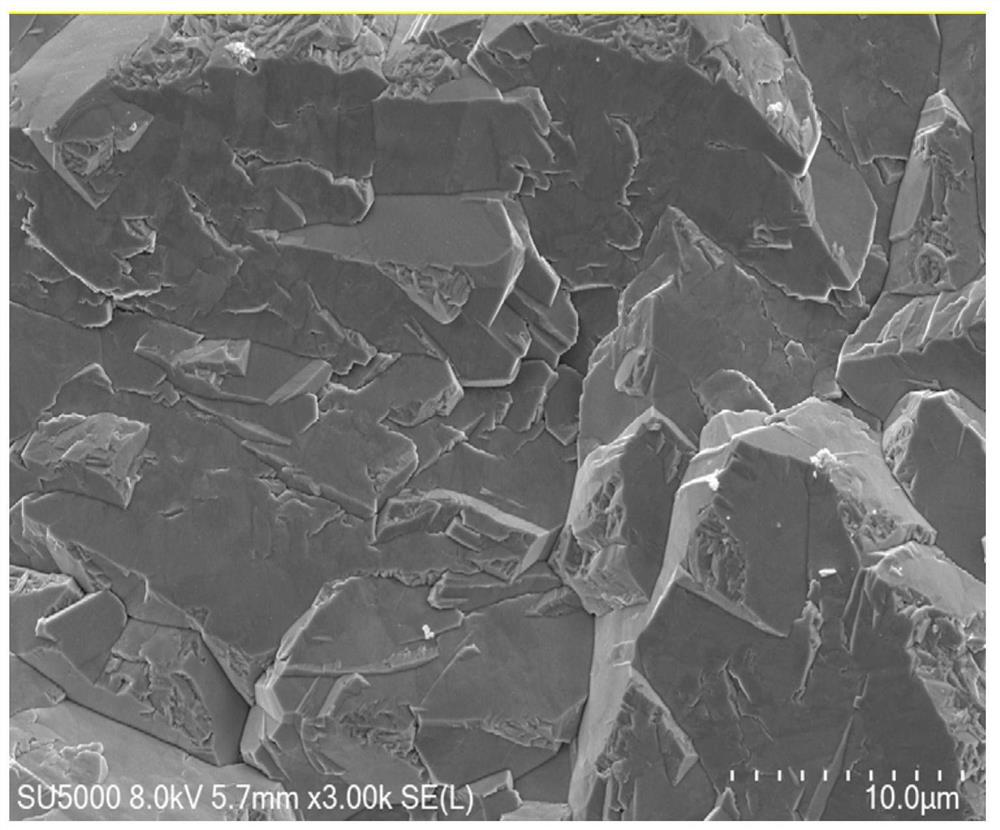

[0035] S1. Preparation of Ti matrix: Mechanically polish the Ti matrix with sandpaper until it is smooth without traces, and then ultrasonically treat it in acetone, absolute ethanol, and deionized water for 5 to 15 minutes, wherein the acetone, the absolute ethanol, and Before the ultrasonic treatment of the deionized water, the Ti substrate needs to be cleaned with deionized water.

[0036] Further, in a preferred embodiment of the present invention, the size of the Ti substrate is 1.5-2.5 cm×1.5-2.5 cm×0.4-0.6 cm. Preferably, the size of the Ti substrate is 2cm×2cm×0.5cm. The steps of mechanical polishing with sandpaper are as follows: first use 750-850 mesh sandpaper to polish the Ti substrate until it is smooth without traces, and then use 350-450 mesh sandpaper to polish the Ti substrate until it is smooth without traces. Preferably, 800-mesh and 400-mesh sandpaper are selected to successively polish the Ti substrate.

[0037] S2,TiO 2 -Preparation of the bottom layer...

Embodiment 1

[0047] A kind of TiO provided by this embodiment 2 -NTs / Sb-SnO 2 / PbO 2 Electrode, which is prepared by the following method:

[0048] (1) Cut the titanium foil into thin slices with a specification of 2cm×2cm×0.5cm, and sand it successively with 800-mesh and 400-mesh sandpaper to remove oxides on the surface of the titanium foil. Then, at room temperature, the titanium foil was ultrasonically cleaned with acetone, absolute ethanol, and deionized water for 10 min, respectively. The titanium foil must be washed with deionized water between each step, and finally stored in absolute ethanol.

[0049] (2) The titanium foil pretreated in step (1) is used as the anode, the platinum wire is used as the cathode, and ethylene glycol, NH 4 F aqueous solution was used as the electrolyte for anodic oxidation at a voltage of 60V for 1h. After the anodic oxidation was finished, it was washed three times with deionized water, placed in a muffle furnace, and calcined at a high temperatur...

Embodiment 2

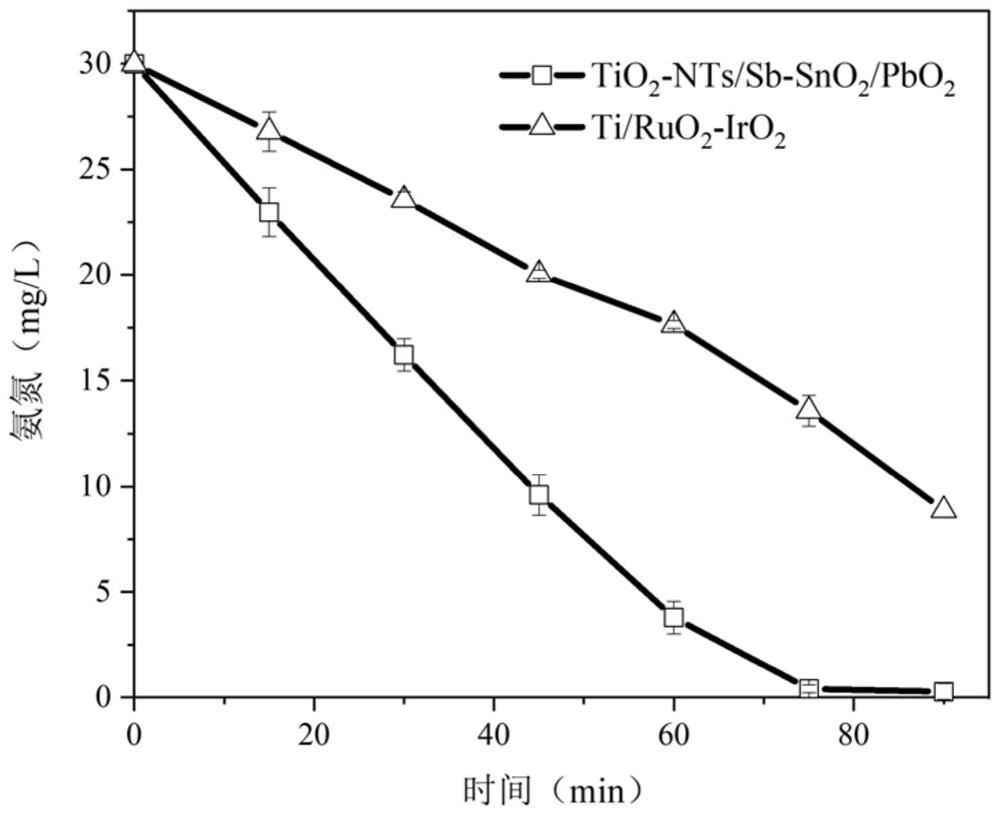

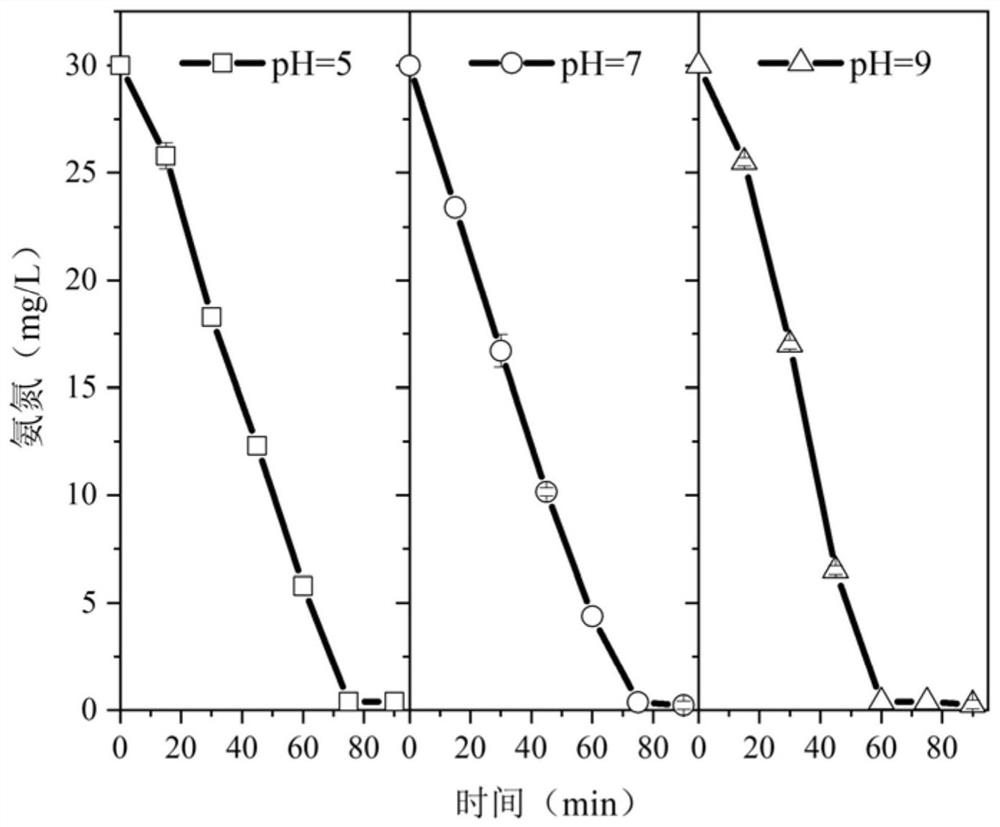

[0054] A kind of TiO that utilizes above-mentioned preparation is provided in the present embodiment 2 -NTs / Sb-SnO 2 / PbO 2 The method for removing ammonia nitrogen in water by electrode electrocatalytic oxidation comprises the following steps:

[0055] The TiO that embodiment 1 makes 2 -NTs / Sb-SnO 2 / PbO 2 As the anode and the titanium sheet as the cathode, configure the target solution NH 4 Cl, and introduce 1000mg / L of Cl - , adjust the water temperature to 25°C, and control the current density to 10mA / cm 2 , and the electrocatalytic oxidation reaction was carried out under the condition of pH=7. Liquid samples were taken from the reactor periodically. Among them, in the target solution NH 4 In Cl, the initial ammonia nitrogen concentration is 30mg / L.

[0056] The ammonia nitrogen value and total nitrogen value of the samples were tested by Nessler's reagent ultraviolet spectrophotometry and alkaline potassium persulfate ultraviolet spectrophotometry, respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com