Preparation method of fluorescent material for PDP

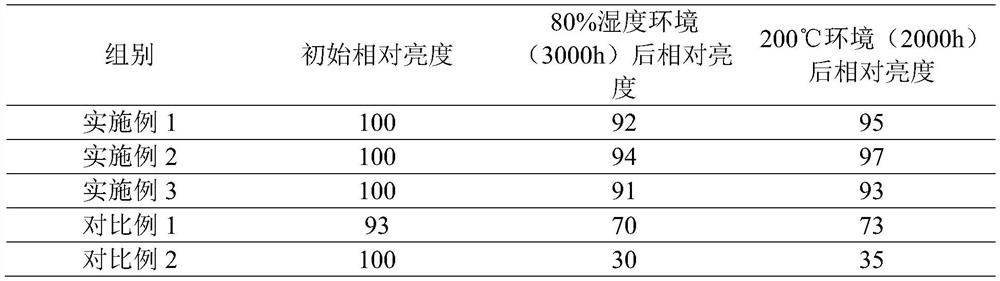

A technology of fluorescent materials and phosphors, applied in the field of fluorescent materials, can solve problems such as the decline of luminous characteristics, achieve the effects of improving service life, reducing the impact of hydrothermal environment, and avoiding the decline of display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Method for preparing one kind of PDP fluorescent material, comprising the step of:

[0023] Step a: selecting the molecular formula Y 0.88 (La, Sc, Bi) 0.02 BO 3 : Eu 3+ Fluorescent material, a fluorescent material is made into a spare phosphor particles, phosphor particles of diameter of 4 m; preparation method of the prior art fluorescent material is, for example, mixed oxides and boric acid after the relevant elements to at 500 ℃ for 2 hours, cooled and milled for 3 hours was placed 1000 ℃ again to obtain the (same below).

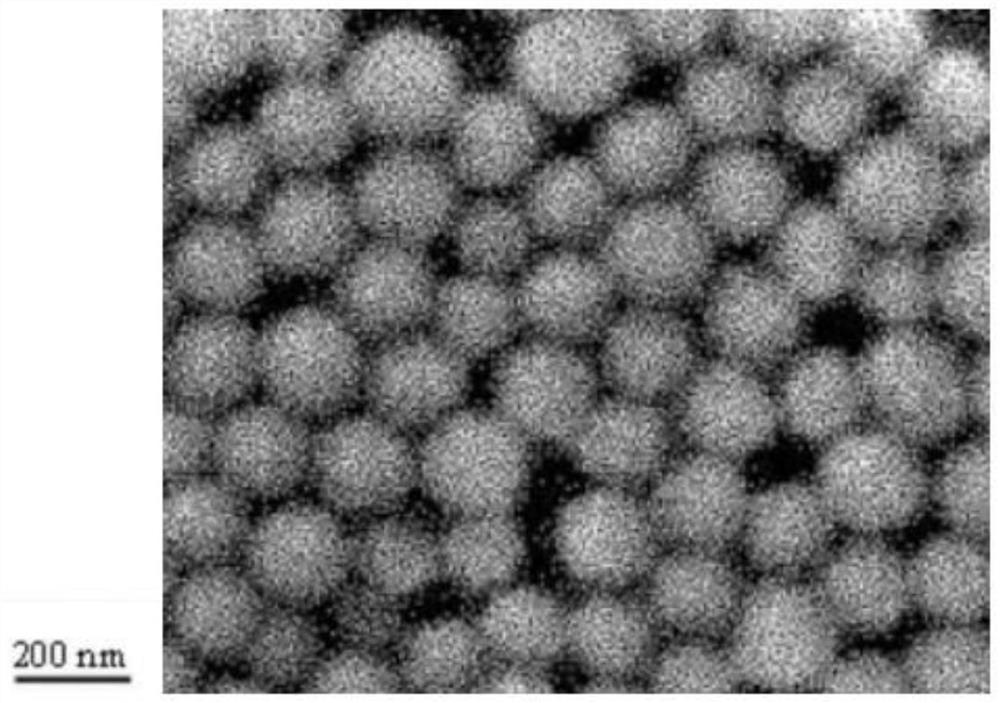

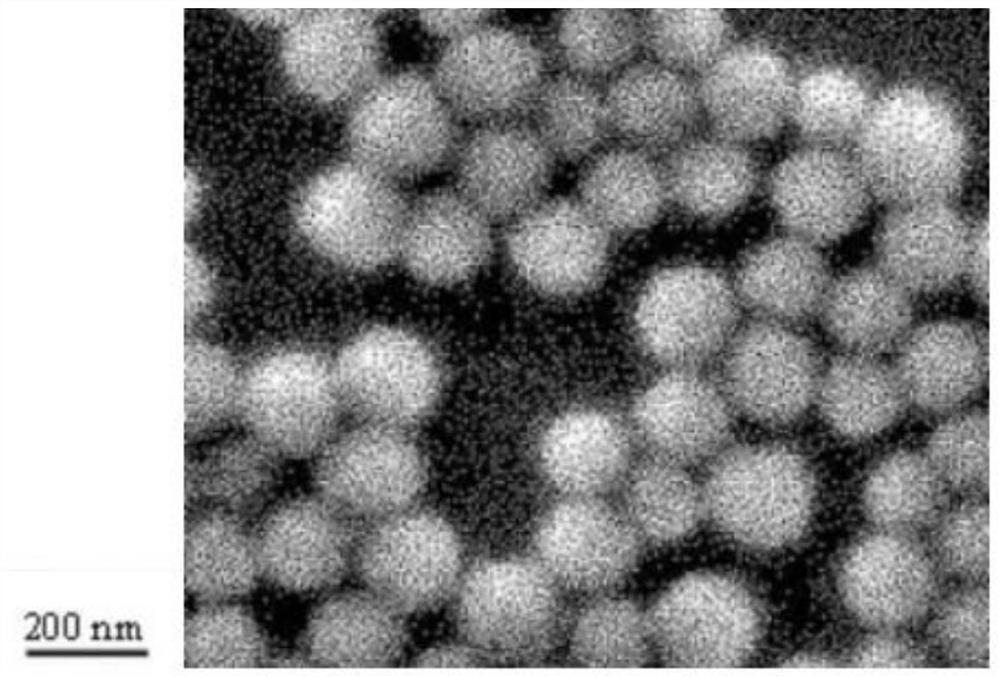

[0024] Step two: Preparation of nano-SiO 2 Microsphere suspension standby, in particular: ethanol, ammonia water and deionized water were mixed was added n-methyl silicate, the rotational speed at 400rpm, the reaction was stirred 12h, was separated, washed with nanoscaled SiO 2 Microspheroidal particles, then nano-SiO 2 Microsphere particles are dispersed in water to obtain 3 times the amount of nano-SiO 2 Microsphere suspension;

[0025] Step 3: the...

Embodiment 2

[0027] Method for preparing one kind of PDP fluorescent material, comprising the step of:

[0028] Step a: selecting the molecular formula Y 0.85 (La, Sc, Bi) 0.05 BO 3 : Eu 3+ Fluorescent material, wherein the phosphor particles made of a fluorescent material standby, the particle size of the phosphor particles was 7 m;

[0029] Step two: Preparation of nano-SiO 2 Microsphere suspension standby, in particular: ethanol, ammonia water and deionized water were mixed was added tetraethylorthosilicate, the rotational speed at 500rpm, the reaction was stirred 10H, separated, washed with nanoscaled SiO 2 Microspheroidal particles, then nano-SiO 2 Microsphere particles are dispersed in water to obtain an amount of 6 times the nano-SiO 2 Microsphere suspension;

[0030] Step 3: the phosphor particles and a step of two step nano-SiO 2 Microsphere suspension of 2: 1 mass ratio of uniformly mixed and stirred, sonicated for 2h at intervals during the reaction the dispersion was stirred 20min,...

Embodiment 3

[0032] Method for preparing one kind of PDP fluorescent material, comprising the step of:

[0033] Step a: selecting the molecular formula Y 0.82 (La, Sc, Bi) 0.08 BO 3 : Eu 3+ Fluorescent material, wherein the phosphor particles made of a fluorescent material standby, the particle size of the phosphor particles is 10 m;

[0034] Step two: Preparation of nano-SiO 2 Microsphere suspension standby, in particular: ethanol, ammonia water and deionized water were mixed was added n-propyl silicate, the rotational speed at 600rpm, the reaction was stirred 8h, separated, washed with nanoscaled SiO 2 Microspheroidal particles, then nano-SiO 2 Microsphere particles are dispersed in water to obtain an amount of 8 times the nano-SiO 2 Microsphere suspension;

[0035] Step 3: the phosphor particles and a step of two step nano-SiO 2 Microsphere suspension of 1: 1.5 by mass ratio were mixed and stirred uniformly, 3h carried out in a stirred reactor at intervals during the ultrasonic dispersion 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com