Pouring polyurethane resin for wind power blades and preparation method thereof

A technology of polyurethane resin and wind power blades, which is applied in the field of wind power, can solve the problems of short gel time, moisture sensitivity of polyurethane, and bulging, etc., and achieve the effect of simple preparation method, low moisture sensitivity and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of pouring polyurethane resin for wind power blades of the present invention comprises the following steps:

[0045] a. Preparation of component A: After the reaction kettle is dried, add polymerized isocyanate, then add isocyanate monomer, and finally add initiator, stir and mix evenly under a protective atmosphere to obtain component A;

[0046] b. Preparation of component B: After the reactor is dried, add 2-functionality polyether polyol, then add 3-functionality polyether polyol, 2 / 5~3 / 5 reactive diluent, heat up to 60~80℃ , add water remover, stir for 20-40min; cool down to below 30°C, add the remaining active diluent, mix well, then add defoamer, catalyst and accelerator to obtain combination B.

[0047] Wherein, there is no chronological order between step a and step b, step a can be performed first to obtain component A, and then step b can be performed to obtain component B; step b can also be performed first to obtain component B, and t...

Embodiment 1~4

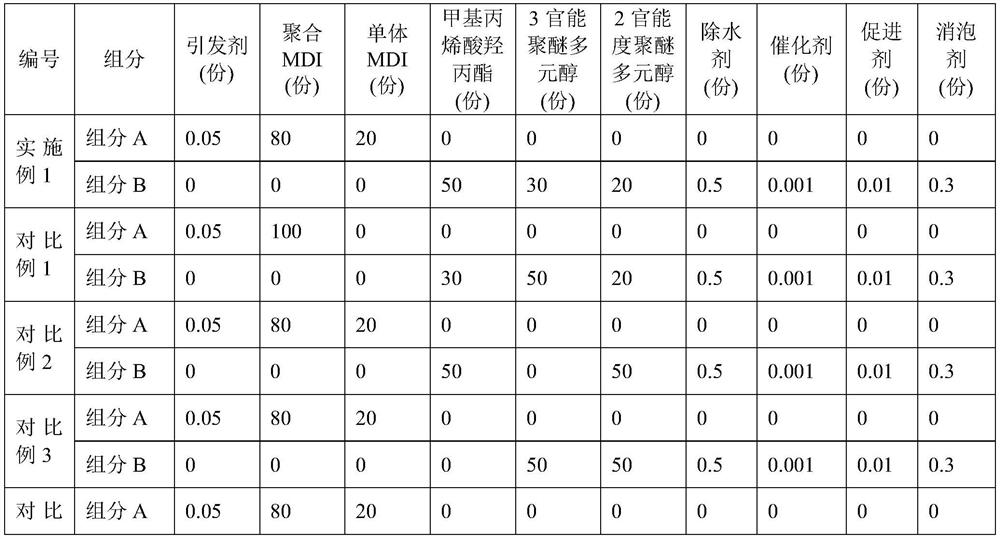

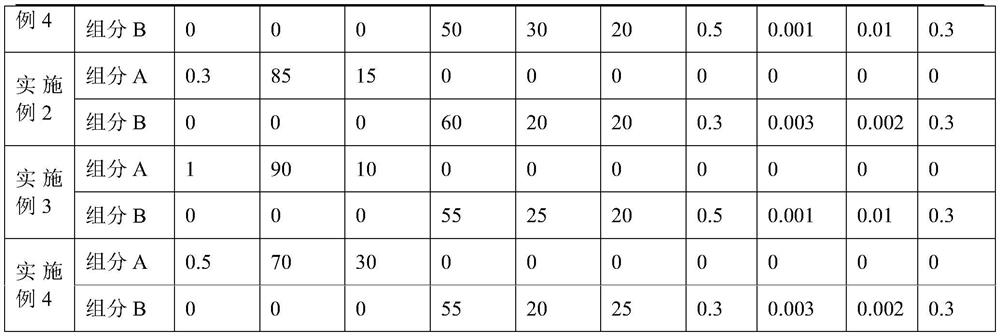

[0073] The product formula is shown in Table 1. Wherein, the initiators of embodiment 1 and comparative examples 1 to 4 all adopt cumene hydroperoxide, the initiator of embodiment 2 adopts methyl ethyl ketone peroxide, and the initiator of embodiment 3 adopts tertiary 2-ethylhexanoic acid peroxide Butyl ester, the initiator of embodiment 4 adopts tert-butyl peroxybenzoate. The 3-functional polyether polyol used in Comparative Example 4 is a polyglycerol polyol with a functionality of 3, the brand name is VORANOL TM 2070, the trifunctional polyether polyols used in the remaining examples and comparative examples are cardanol-modified polyether polyols with a functionality of 3, brand NX9008L.

[0074] Table 1

[0075]

[0076]

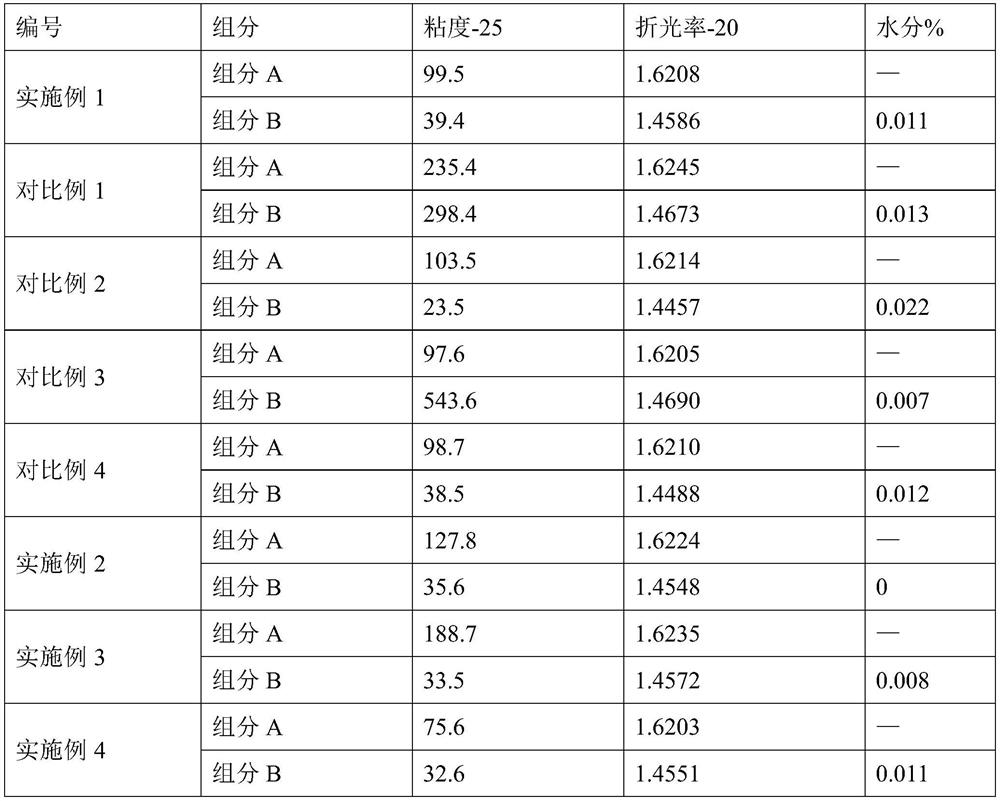

[0077] Product parameters such as viscosity, refractive index, and moisture are shown in Table 2. In Table 2, "—" means no detection.

[0078] Table 2

[0079]

[0080] The product preparation method is as follows:

[0081] Preparation of co...

Embodiment 5

[0087] The pouring preparation of embodiment 5 pouring body

[0088] The preparation of the pouring body in this experiment is at room temperature, the temperature is 20-25°C, and the humidity is 50-65%. There is no need to control the temperature and humidity in the room or operate it in a vacuum glove box.

[0089] 1. Mix the prepared components A and B according to the ratio of 92 parts of component A and 100 parts of component B, mix and stir evenly, put the uniformly mixed composition into the vacuum defoaming machine, turn on the vacuum defoaming for 10 minutes, The vacuum pressure is -0.095Mpa.

[0090] 2. Pour the prepared mixture carefully into the pre-prepared glass interlayer. The glass interlayer is sealed with a 4mm-thick silicone rope around it, and a glue injection port is left. The inner glass surface is coated with a release agent. Combine Once done, secure with threaded clips.

[0091] 3. After pouring into the glass interlayer, seal it with black sealant i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com