Low-viscosity flame-retardant casting glue and preparation method thereof

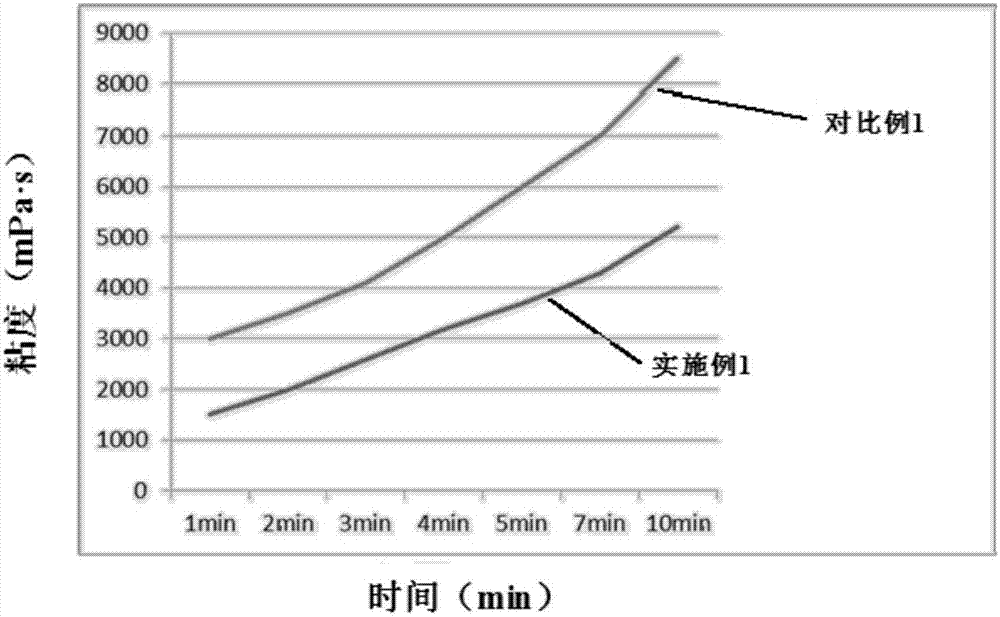

A technology of potting glue and base glue, applied in the field of flame retardant materials, can solve the problems of insufficient safety of components, easy occurrence of air bubbles, poor leveling, etc., to achieve good flame retardancy, smooth discharge of air bubbles, and low mixing. The effect of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

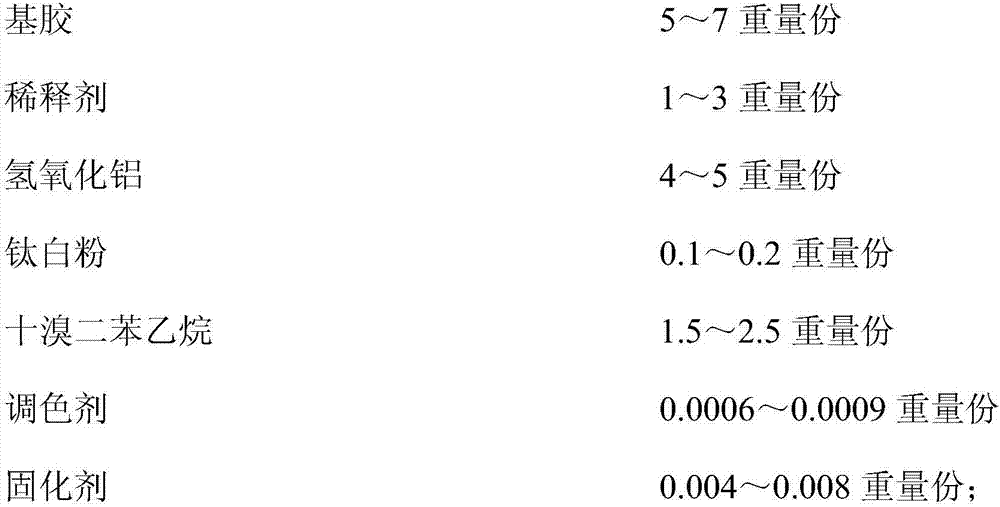

[0074] In this embodiment, the flame retardant encapsulant is composed of Agent A and Agent B at a mass ratio of 5:1, and Agent A is mainly composed of the following components by weight:

[0075]

[0076] The B agent is mainly composed of the following components by weight:

[0077]

[0078]

[0079] The preparation method is as follows:

[0080] (1) Stir and mix 107 glue with a viscosity of 750mPa·s and silicone oil for 10min at a stirring speed of 20r / min under a vacuum condition of -0.1MPa;

[0081] (2) Add aluminum hydroxide and titanium dioxide to the mixture obtained in step (1), stir and mix for 15min under normal pressure at a stirring speed of 20r / min;

[0082] (3) Add ultramarine blue and curing agent to the mixture obtained in step (2), and stir and mix for 20min at a stirring speed of 40r / min under a vacuum condition of -0.1MPa in vacuum;

[0083] (4) Add decabromodiphenylethane to the mixture obtained in step (3), stir and mix for 5min at a stirring sp...

Embodiment 2

[0086] In this embodiment, the flame retardant encapsulant is composed of Agent A and Agent B at a mass ratio of 6:1, and Agent A is mainly composed of the following components by weight:

[0087]

[0088]

[0089] The B agent is mainly composed of the following components by weight:

[0090]

[0091] The preparation method is as follows:

[0092] (1) Stir and mix 107 glue with a viscosity of 750mPa·s and silicone oil at a vacuum condition of -0.09MPa at a stirring speed of 15r / min for 13min;

[0093] (2) Add aluminum hydroxide and titanium dioxide to the mixture obtained in step (1), and stir and mix for 20min under normal pressure at a stirring speed of 10r / min;

[0094] (3) Add ultramarine blue and curing agent to the mixture obtained in step (2), and stir and mix for 15 minutes at a stirring speed of 50 r / min under a vacuum condition of -0.09 MPa in a vacuum;

[0095] (4) Add decabromodiphenylethane to the mixture obtained in step (3), stir and mix for 5min at a s...

Embodiment 3

[0098] In this embodiment, the flame retardant encapsulant is composed of Agent A and Agent B at a mass ratio of 5.5:1, and Agent A is mainly composed of the following components by weight:

[0099]

[0100] The B agent is mainly composed of the following components by weight:

[0101]

[0102] The preparation method is as follows:

[0103] (1) Stir and mix 107 glue with a viscosity of 750mPa·s and silicone oil at a vacuum of -0.095MPa for 15min at a stirring speed of 10r / min;

[0104] (2) Add aluminum hydroxide and titanium dioxide to the mixture obtained in step (1), stir and mix for 25min under normal pressure at a stirring speed of 15r / min;

[0105] (3) Add ultramarine blue and curing agent to the mixture obtained in step (2), and stir and mix for 20min at a stirring speed of 45r / min under a vacuum condition of -0.095MPa in vacuum;

[0106] (4) Add decabromodiphenylethane to the mixture obtained in step (3), stir and mix for 10min under normal pressure at a stirrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com