5-aminotetrazole zinc complex, and synthetic method and application thereof

A technology of zinc amino tetrazolium and amino tetrazolium, which is applied to zinc organic compounds, compositions containing nitrated metal organic compounds, 2/12 group organic compounds without C-metal bonds, etc., and can solve unfavorable missiles Guidance, staff and environmental hazards, etc., to achieve the effect of simple synthesis method, good thermal stability and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

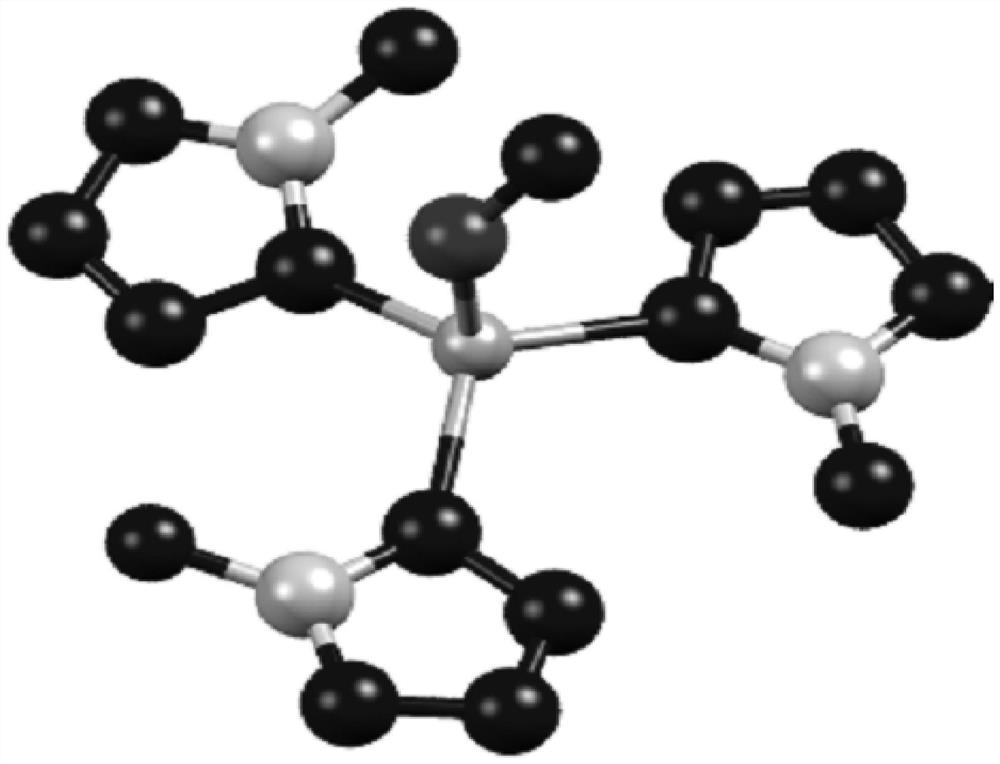

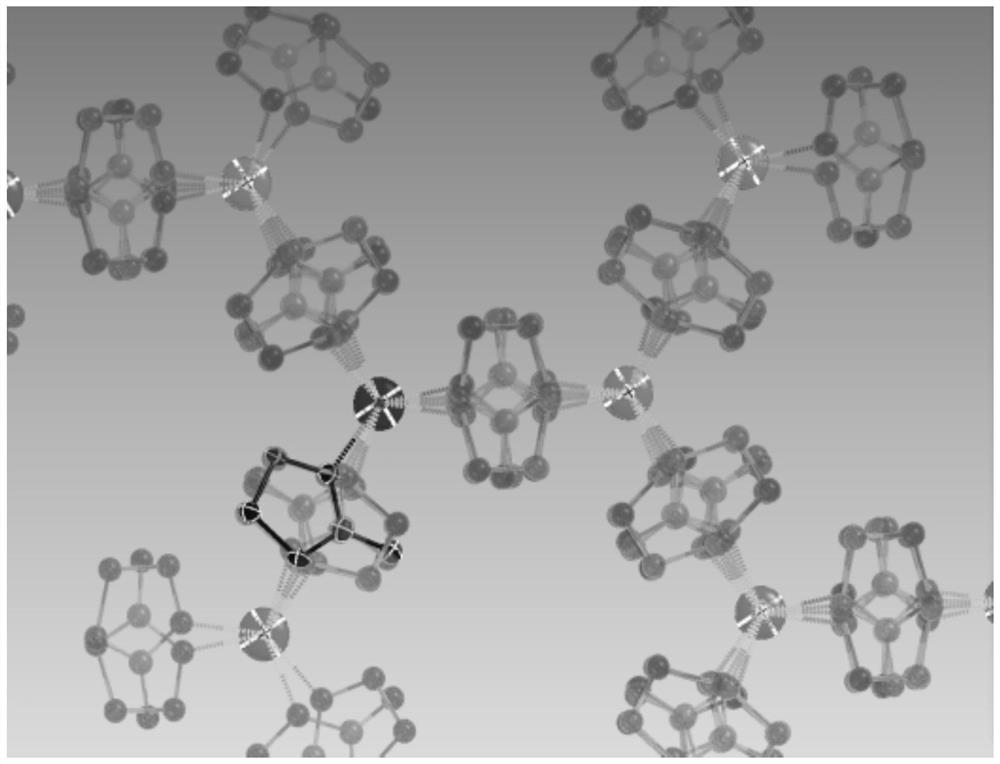

[0035] This embodiment provides a kind of energetic complex of 5-aminotetrazole zinc, and its structural formula is as follows:

[0036]

[0037] The synthetic method of the 5-aminotetrazole zinc energetic complex of the present embodiment, the method comprises the following steps:

[0038] In a 10mL three-necked flask, add 8mL of N,N-dimethylformamide and 2mL of water, add 36.3mg (0.1mmol) of 5-aminotetrazole and 38.0mg (0.2mmol) of zinc nitrate hexahydrate under stirring, and stir until All dissolved, heated to 90 ° C, and reacted for 24 hours. Return to room temperature after completion of the reaction, filter and dry to obtain a white solid with a yield of 98.5%.

[0039] The 5-aminotetrazolium zinc energetic complex of this example is used as a burning rate catalyst for propellants.

Embodiment 2

[0041] This example provides a 5-aminotetrazole zinc energetic complex, the structural formula of which is the same as that of Example 1.

[0042] The synthetic method of the 5-aminotetrazole zinc energetic complex of the present embodiment, the method comprises the following steps:

[0043] In a 250mL three-necked flask, add 80mL of N,N-dimethylformamide and 20mL of water, add 363mg (1mmol) of 5-aminotetrazole and 380mg (2mmol) of zinc nitrate hexahydrate under stirring, stir until completely dissolved, and heat up To 90°C, react for 24h. Return to room temperature after completion of the reaction, filter and dry to obtain a white solid with a yield of 89%.

[0044] The 5-aminotetrazolium zinc energetic complex of this example is used as a burning rate catalyst for propellants.

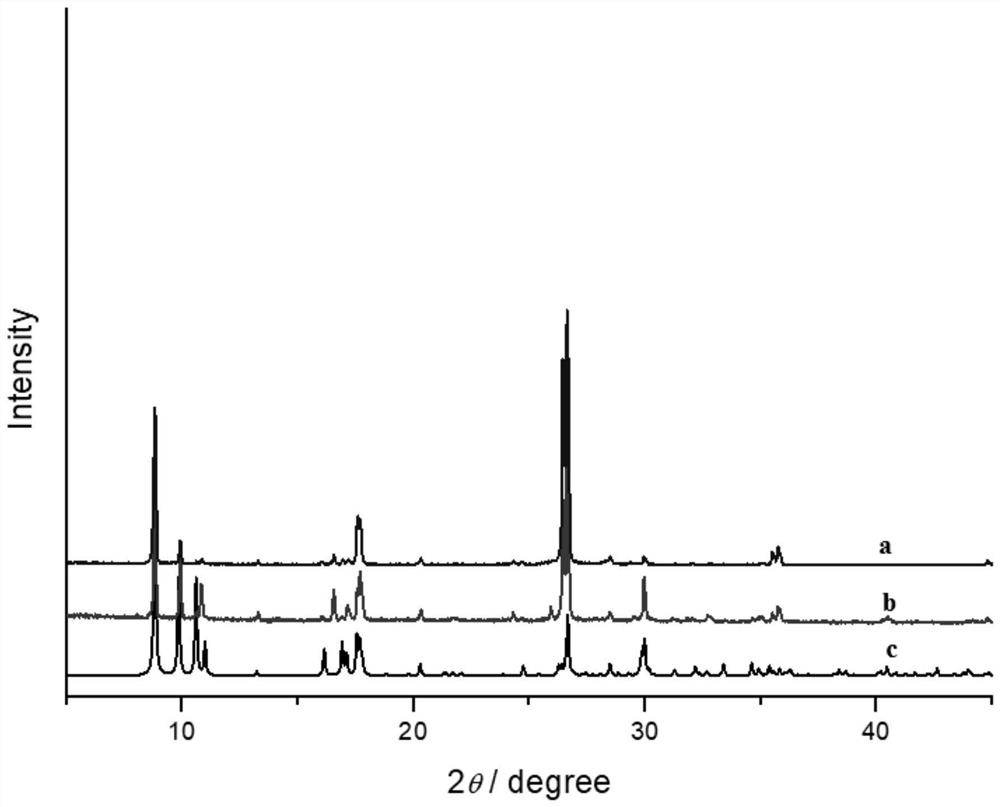

[0045] Structure Identification:

[0046] Infrared spectrum (KBr, cm -1 ): 3276 (-NH 2 stretching vibration), 1653, 1479 (C=N stretching vibration), 1467, 1017 (-NO 2 stretching vibration).

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com