Preparation for improving anaerobic fermentation efficiency of organic solid waste and preparation method and application of preparation

A technology of anaerobic fermentation and organic solid waste, applied in the direction of biological sludge treatment, etc., can solve the problems of narrow application range and achieve the effects of improving stability, wide application range and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

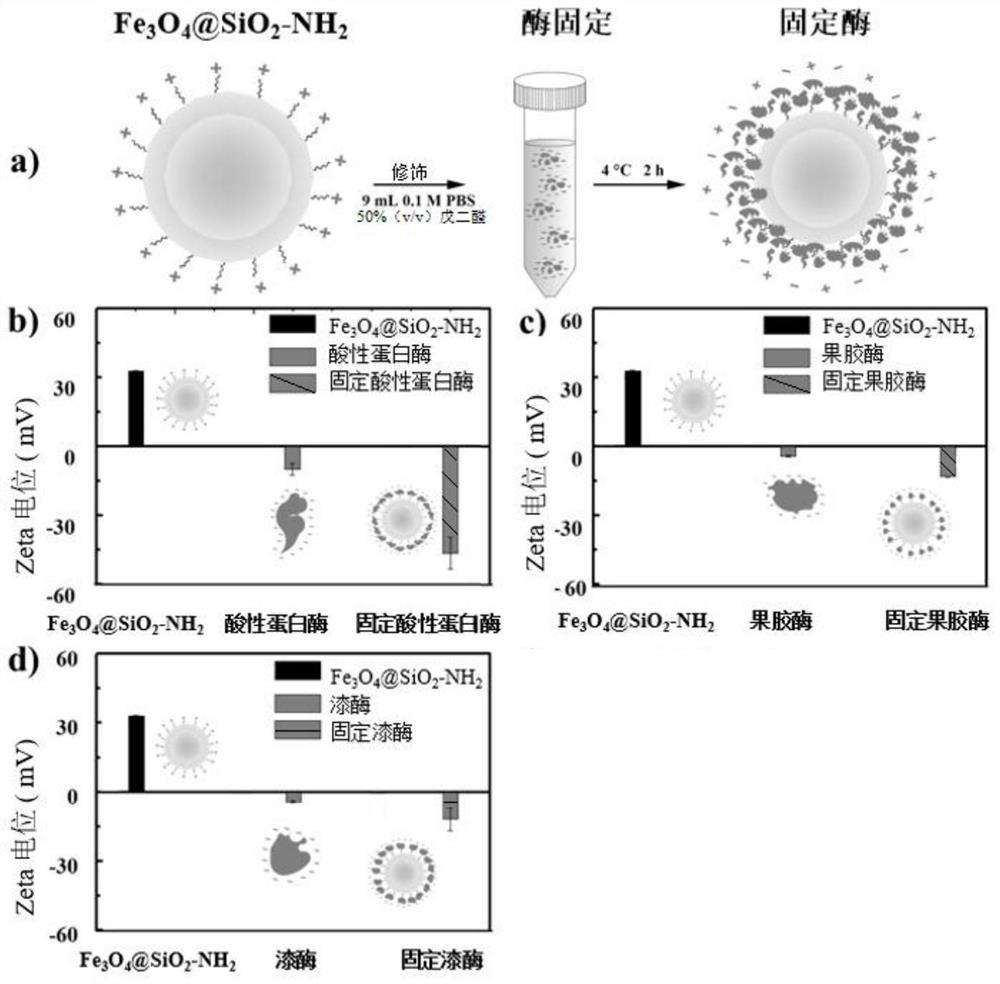

[0057] In the example, Fe 3 o 4 @SiO 2 -NH 2 The preparation method comprises the steps:

[0058] 1) Fe 3 o 4 Preparation of NPs: 1.3g FeCl 3 Disperse in 40.0mL ethylene glycol, ultrasonically disperse for 10-60min, make it fully dissolve into brick red, add 0.48g sodium citrate dihydrate and 2.40g sodium acetate, stir mechanically at 300-600r / min for 20-60min, fully dissolve into yellow-brown, then poured into the polytetrafluoroethylene lining in the autoclave, reacted at 200°C for 10 hours at high temperature, magnetically separated, and then magnetically separated the solid according to the volume ratio: 0.1M dilute nitric acid = 10:1 by adding 0.1 M diluted nitric acid, ultrasonicated for 10min, washed with ethanol and deionized water in turn, then dispersed in deionized water, frozen at -70°C for 12h, and powdered Fe was obtained after freeze-drying 3 o 4 NPs;

[0059] 2) Fe 3 o 4 @SiO 2 -NH 2 Preparation: take 0.05g Fe 3 o 4 NPs were dispersed into a mixt...

Embodiment 1

[0062] A preparation method for improving the efficiency of anaerobic fermentation of organic solid waste, comprising the following steps:

[0063] (1) Preparation of immobilized enzyme:

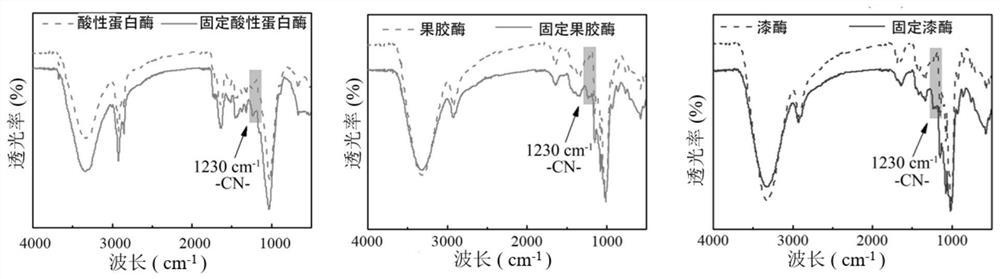

[0064] A1: Preparation of immobilized acid protease: 0.1g of Fe with a particle size of about 500nm 3 o 4 @SiO 2 -NH 2 Disperse in 9mL of phosphate buffer solution (pH 7.8), and sonicate for 10 minutes, ultrasonic power 200W, to obtain a dispersed mixture; add 1mL of 50% (v / v) glutaraldehyde solution to the above dispersed mixture, 25 ℃, 200rpm shaking and washing for 2 hours, and magnetically separate the solid;

[0065] A2: Redissolve the solid obtained in step A1 with 20 mL of phosphate buffer with pH 5.2, then add 0.05 g of acid protease (50u / mg), react for 2 hours at 4°C and 200 rpm, and wash with phosphate buffer with pH 5.2 3 to 5 times, then absorb the solid with a magnet, and then freeze-dry to obtain immobilized acid protease (42.51u / mg).

[0066] B1: Preparation of immobiliz...

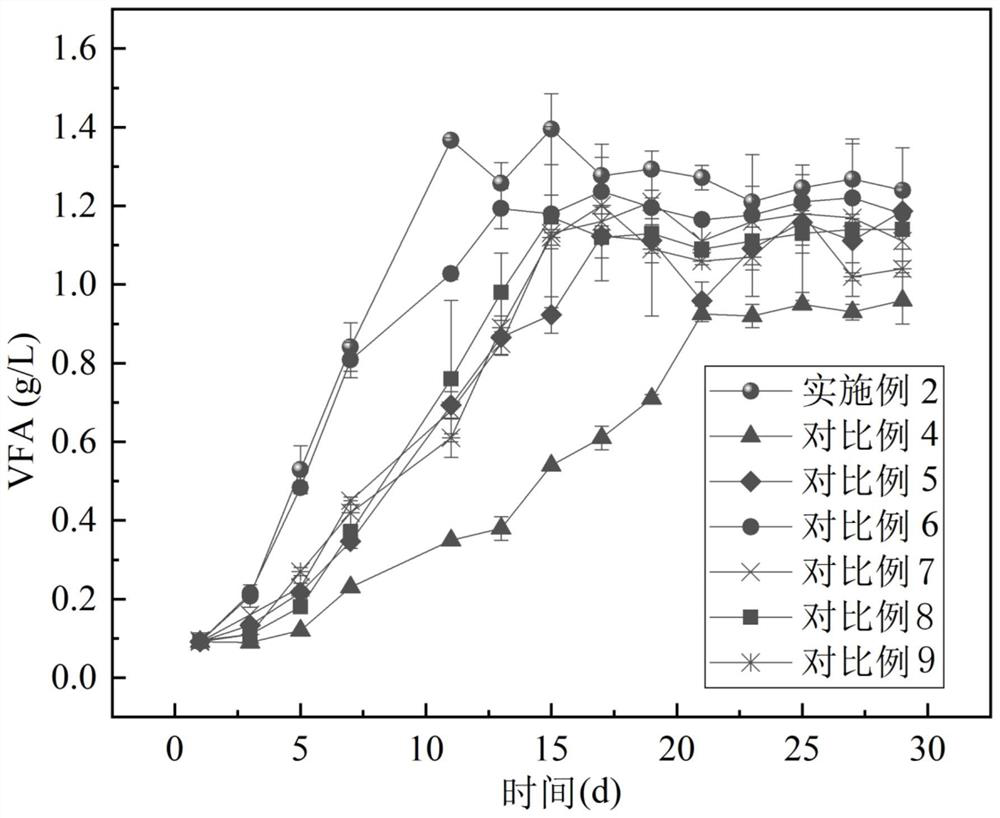

Embodiment 2

[0087] The present embodiment is basically the same as Example 1, except that the enzymes selected in the present embodiment 2 step (1) are respectively 0.05g acid protease (50u / mg), 0.05g pectinase (500u / mg), 0.05g cellulase (500u / mg) and 0.05g laccase (500u / mg), finally prepared immobilized acid protease (48.19u / mg), immobilized pectinase (459.23u / mg), immobilized cellulase ( 468.39 u / mg) and immobilized laccase (467.77u / mg);

[0088] Wherein, the preparation method of immobilized acid protease (48.19u / mg), immobilized pectinase (459.23u / mg) and immobilized laccase (467.77u / mg) is with embodiment 1;

[0089] The preparation method of immobilized cellulase is as follows: D1: the preparation of immobilized cellulase (468.39u / mg): the Fe of 0.1g particle diameter about 500nm 3 o 4 @SiO 2 -NH 2 , dispersed in 9 mL of phosphate buffer solution (pH 7.8), and sonicated for 10 minutes with an ultrasonic power of 200 W to obtain a dispersed mixture; 1 mL of 50% (v / v) glutaraldehy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com