Hub bearing with spline structure

A wheel hub bearing and spline technology, applied in the field of wheel hub bearings, can solve the problems of reducing the use effect of the overall structure, difficulty in replenishing oil for the hub bearing, and external impurities that easily affect the overall structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

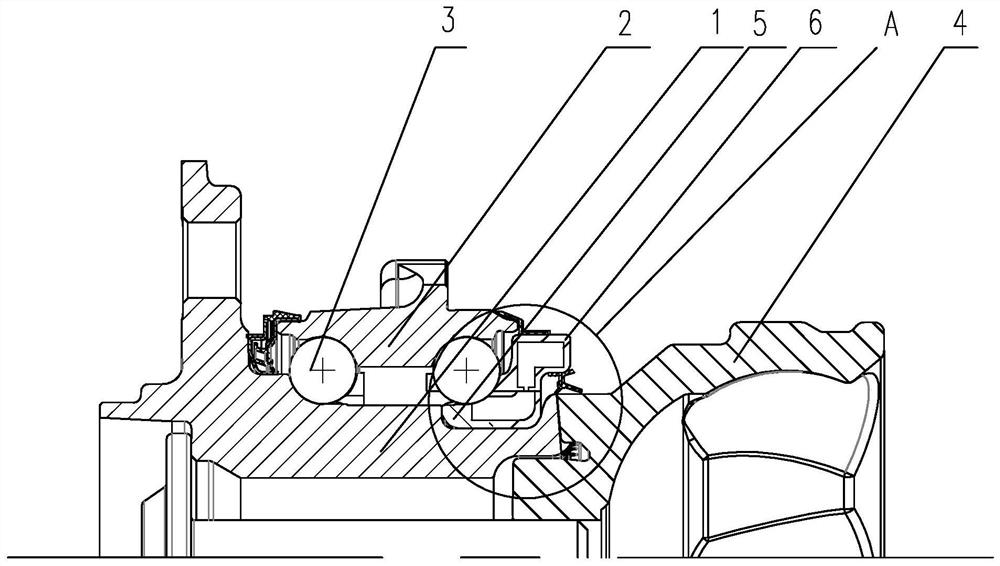

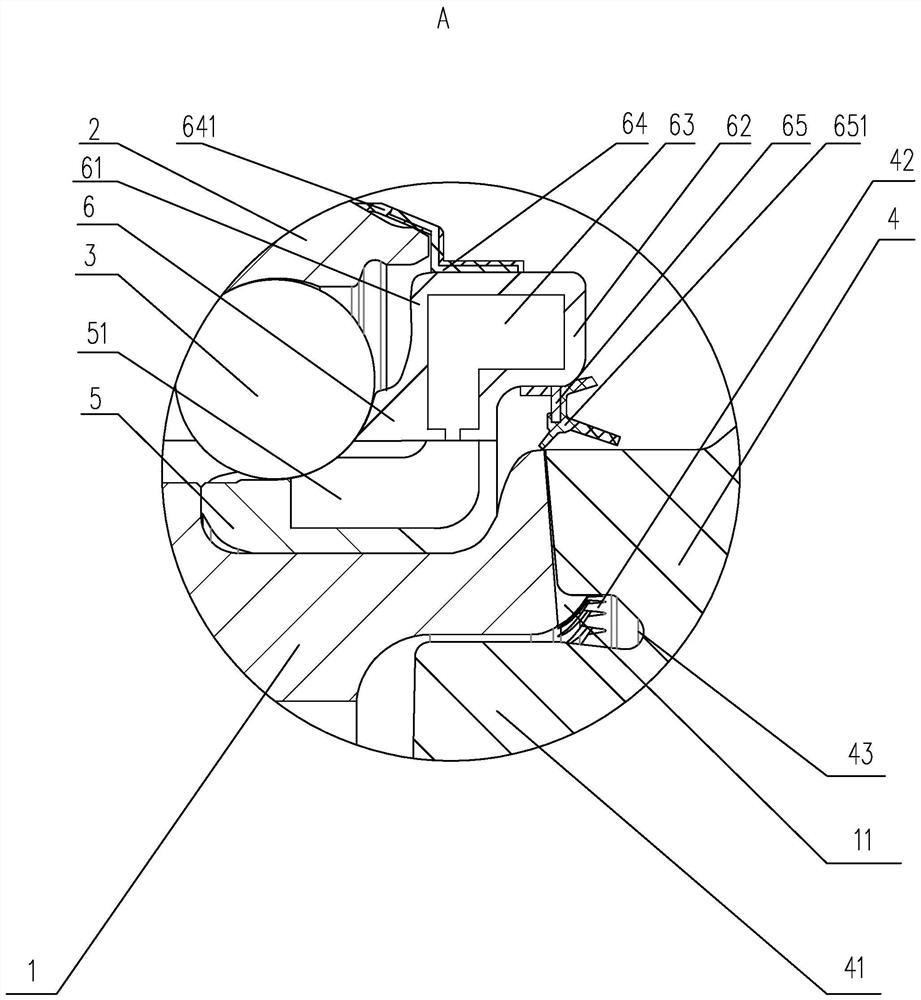

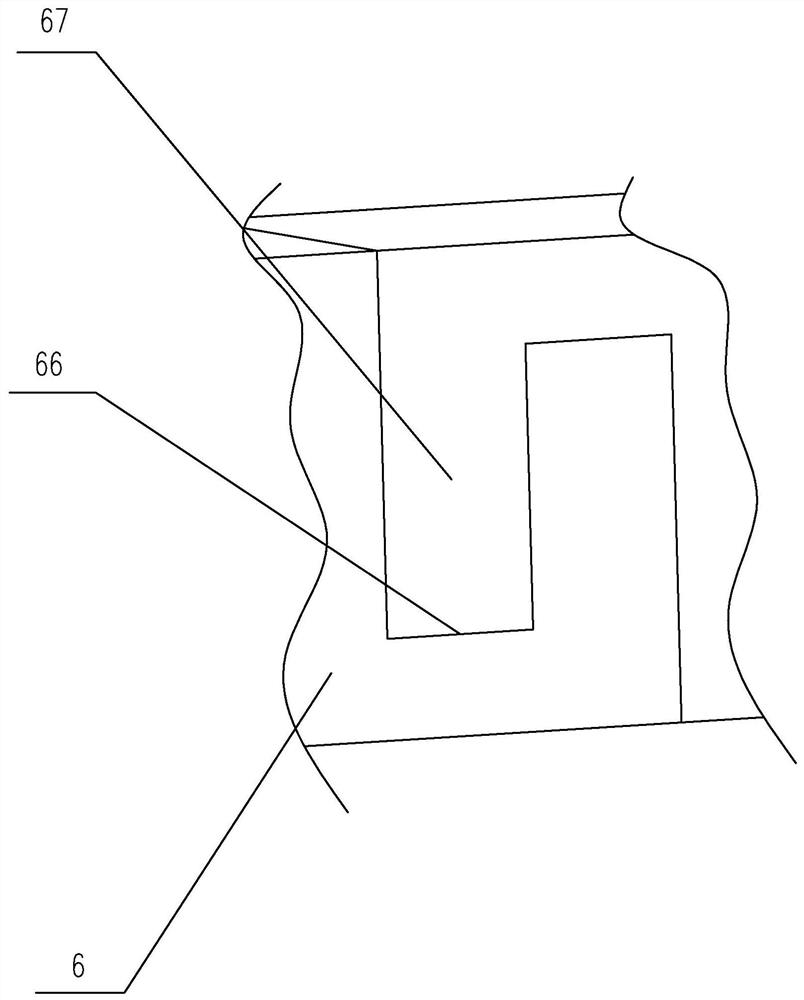

[0023] The present invention has an embodiment of a hub bearing having a spline structure, for example Figure 1 to 3 As shown: including the rotary connector 4, the flange inner ring 1, the flange outer ring 2 and the inner ring, the flange inner ring 1 and the flange outer ring 2 form a first roller, the connection A first roller is provided on the outer wall of the inner ring, and the flange outer ring 2 is provided with a second raceway corresponding to the first raceway, the first raceway and the second roller form a second roller, The first roller 3 is provided in the first roller 3, and a cartridge is formed on the flange inner ring 1, and the connecting inner ring split is provided with a first circle body 5 and a second. A plurality of guide grooves and guide blocks are disposed between the first circular body 5 and the second loop bodies 6, the guide groove and the guide block inserted to form a first circle 5 and the second loop 6 The fixed connection is disposed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com