Erythema-preventing regenerated cellulose fiber containing pearl and traditional Chinese medicine and preparation method of erythema-preventing regenerated cellulose fiber

A technology of regenerated cellulose and traditional Chinese medicine, applied in the field of textile fibers, can solve the problems of being easily weakened by acid and alkali, unable to be released continuously and stably, and achieve the effect of ideal effect, small size and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0033] Pulverization of Experimental Example 1 Pearl

[0034]After the raw pearls are selected and cleaned, they are mixed with water and placed in a stirring ball mill, and the pearls are coarsely crushed to about 5 μm by the pressure and shear force generated. The obtained coarsely crushed pearl slurry is sent into the high-pressure tank of the high-pressure expansion device, and the steam pressurizes the pearl slurry, and then enters the expansion cavity through the expansion valve and returns to normal conditions, and repeats at least three times. Repeated high-pressure expansion for many times - after decompression to conventional conditions, the pearl layer will expand between the layers, easy to loosen, and then grind by jet crushing technology or wet grinding and crushing method. The fineness of the obtained pearl powder reaches D95≤0.1 μm, and the degree of dispersion is greater than 90%. If the particle size of pearl powder is large, it will not only block the machi...

experiment example 2

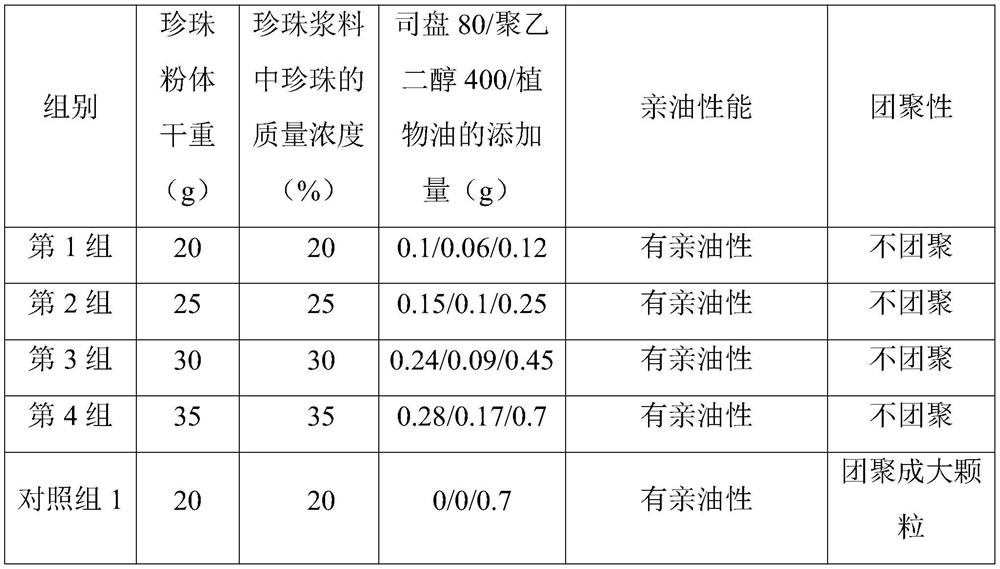

[0035] The pretreatment of experimental example 2 pearls

[0036] Through the pretreatment of the pulverized pearl powder, the effect of pretreatment on improving the lipophilicity and dispersibility of the pearl powder was further explored. Since pearl powder is a hydrophilic and oleophobic substance with a large specific surface area and is easy to agglomerate, it is added to fibers to make textiles, and the skin's absorption effect is poor. If it can be changed from hydrophilic to lipophilic, it can be better in contact with people's skin, and it is more conducive to the effect of pearls. At the same time, the more evenly the pearl powder is dispersed, the more favorable the spinning process and fiber quality will be.

[0037] Add water to the pulverized pearl powder to prepare a 20-35% slurry. The pretreatment method is to add Span 80, polyethylene glycol 400 and vegetable oil, such as palm oil and corn oil, to the pearl slurry. The added amounts of Span 80, polyethylene...

experiment example 3

[0044] Experimental Example 3 Study on the Preparation Technology of Chinese Medicine Extract Microcapsules

[0045] Through the following examples and comparative examples, we explore the process research of preparing microcapsules using artemisinin and its derivatives and borneol as Chinese medicine extracts. Artemisinin and its derivatives are extracted from Artemisia annua plants using existing extraction methods. Ice products are purchased from the market.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com