Catalyst composition and method for preparing hydrocarbon resin by using same

A technology of hydrocarbon resin and catalyst, applied in the field of catalyst composition, which can solve the problems of product quality deterioration, corrosion, large waste water, etc., and achieve the effect of high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] For the preparation of the hydrocarbon resin, as long as the C5 unsaturated hydrocarbon monomer or the C9 unsaturated hydrocarbon monomer used in the technical field is selected, any type can be appropriately selected and applied in the present invention.

[0070] In addition, the monomer mixture may also include isobutene, 2-methyl-1-pentene, 2-methyl-2-pentene, 1,3-hexadiene, 1,4-hexadiene and bicyclic One or more of pentadiene.

[0071] In the present invention, the catalyst represented by Formula 1 can be used at 0.01 wt % or more, 0.02 wt % or more, 0.2 wt % or less, 0.1 wt % or less, 0.05 wt % or less, or 0.03 wt % or less based on the total weight of monomers.

[0072] As described above, the catalyst represented by Formula 1 and the additive may be dissolved in a halogenated hydrocarbon solvent for use. In this case, the catalyst represented by Formula 1 may be used at 5 to 50 ppm by weight or 10 to 40 ppm by weight based on the catalyst composition. Also, the...

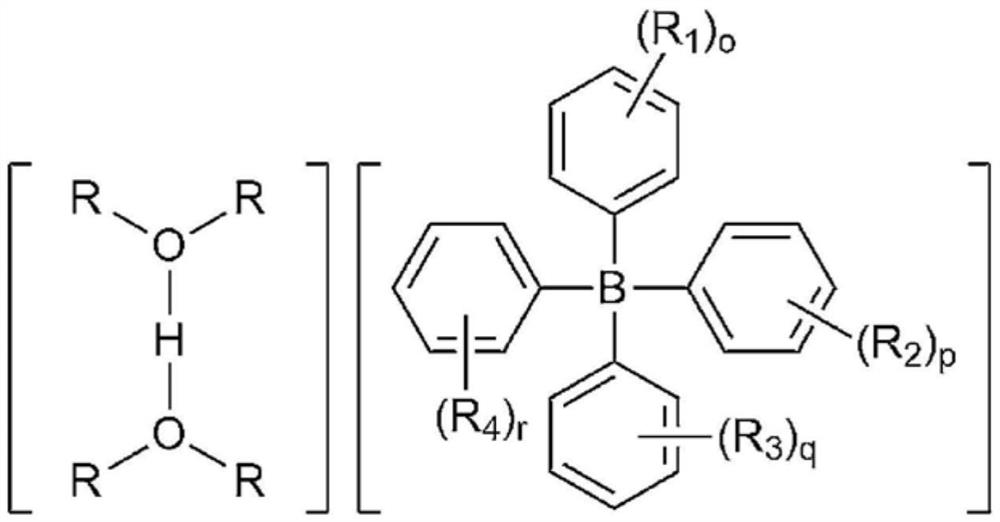

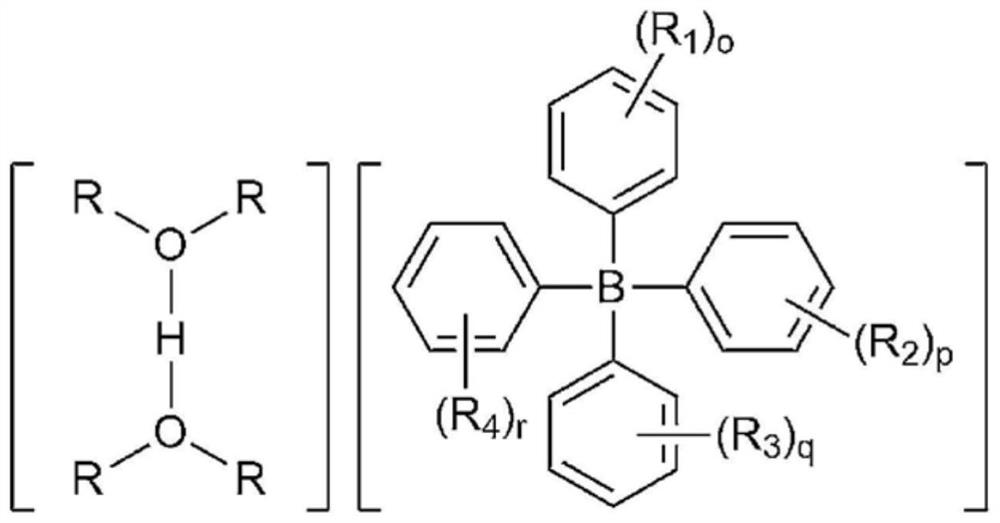

preparation example 1

[0082] In the glove box, 1 g of [H(Et 2 O) 2 ][B(C 6 f 5 ) 4 ] into a round bottom flask, and put 10 mL of dichloromethane into it. At room temperature, 5 equivalents of anhydrous butyl ether (purchased from Sigma Aldrich) were put into the solution and stirred for 30 minutes. After stirring, all solvent was removed under vacuum. The white powder thus obtained was washed by 5 mL x three times using anhydrous hexane, and then dried again under vacuum to obtain [H(nBu 2 O) 2 ][B(C 6 f 5 ) 4 ].

Embodiment 1

[0084] 5 mL of α-methylstyrene monomer and 5 mL of DCM solvent were injected into the vial, the catalyst of Preparation Example 1 (0.02% by weight based on α-methylstyrene) was dissolved in DCM and added thereto, and Additive acetonitrile represented by Formula 2 (the same equivalent as the catalyst of Preparation Example 1) was added, followed by polymerization in an ethanol bath kept at 0° C. for 1 hour. After the reaction was finished, the obtained product was precipitated in excess methanol, and the precipitate was separated by filtration under reduced pressure, dried at room temperature for 24 hours, and at 50°C for 1 hour in vacuum to obtain a hydrocarbon resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com