Test fixture, test system and test method

A technology of fixtures and clamping discs, which is applied in the field of test fixtures, test systems and methods, can solve problems such as complicated test work, inaccurate measurement results, and failure to meet high-temperature test requirements, so as to achieve convenient detection and operation and avoid melting outflow , to avoid the effect of errors in the results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] Step 1: In an anhydrous and oxygen-free environment, weigh solid electrolyte powders of different masses (0.5g-1.0g), and press them into electrolyte discs through a tablet grinding tool. The thickness of the solid electrolyte discs ranges from 0.7mm- 1.5mm.

[0102] In a glove box, 1.0 g of electrolyte powder was put into a tableting mold, and held at a pressure of 10 Mp for 30 min to obtain an electrolyte disc with a diameter of 16 mm and a thickness of 1.13 mm.

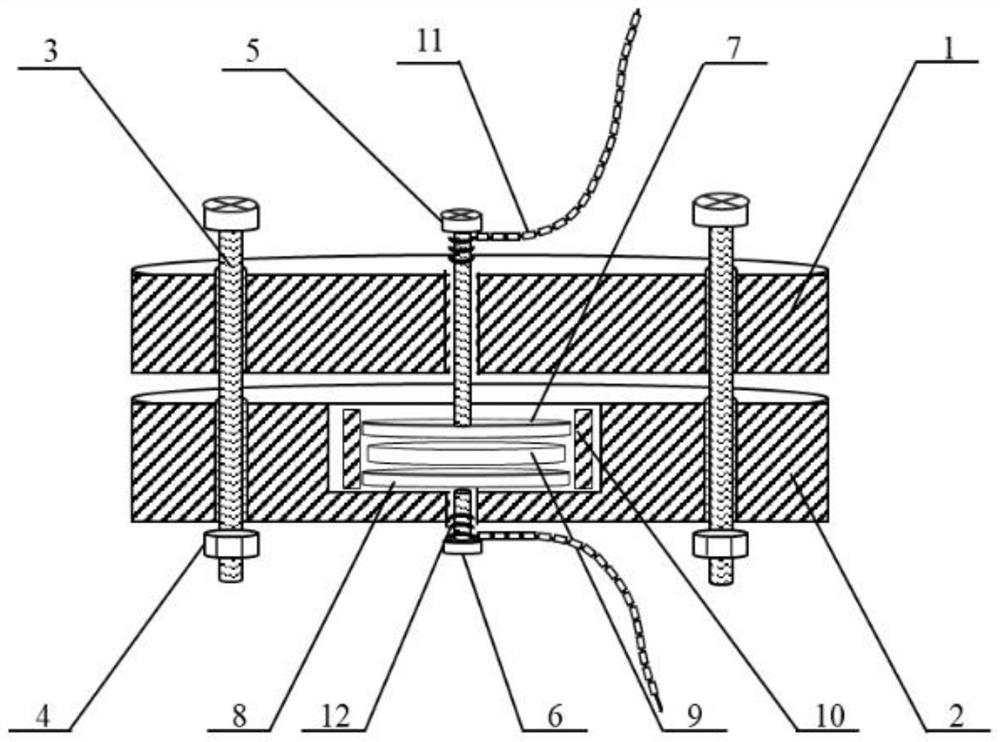

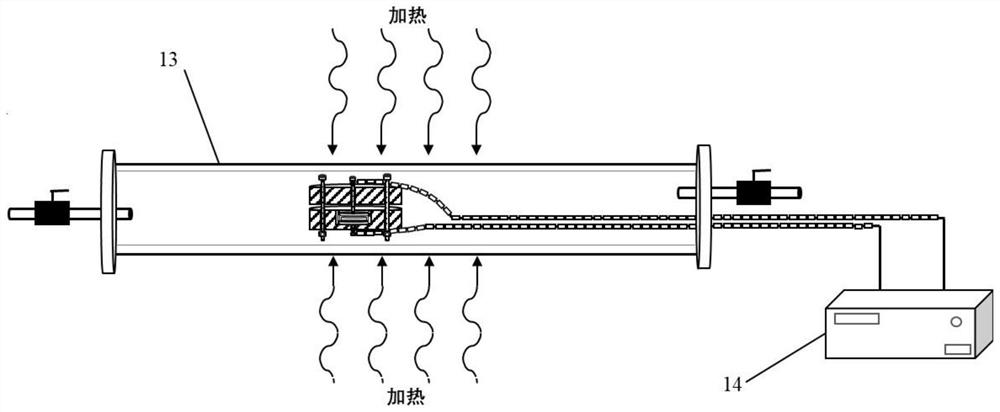

[0103] Put the protective tube 10 into the load tank of the lower clamping plate 2, put the lower current collector 8 in the protective tube 10, place the pressed solid electrolyte sheet on the lower current collector 8, and then place it on the solid electrolyte sheet The upper collector sheet 7, and then cover the upper clamping disc 1 on the lower clamping disc 2, and align the central axes.

[0104] First pass the connecting bolt 3 through the threaded connecting through holes on both sides of the upper...

Embodiment 2

[0109] Weigh 0.35g of positive electrode material in the glove box, put the positive electrode powder into the tableting mold, take it out and keep the pressure at 10Mp pressure for 1min; weigh 0.5g of solid electrolyte, spread the solid electrolyte powder evenly on the tableting mold positive electrode material After taking it out, keep the pressure at 12Mp pressure for 1min; weigh 0.2g of negative electrode material, evenly spread the negative electrode powder on the solid electrolyte in the tablet mold, take it out and keep the pressure at 15Mp pressure for 30min, and eject the mold to get a hot battery cell body battery.

[0110] Put the protective tube 10 into the loading slot of the lower clamping plate 2, put the lower current collector 8 in the cylinder, place the pressed thermal battery unit battery on the lower current collector 8, and then place the thermal battery unit Place the upper current collector 7 on the battery, then cover the upper clamping disc 1 on the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com