Gas chromatography detection process of ethidene diamine

A technology of gas chromatography and ethylenediamine, which is applied in the field of gas chromatography detection technology of ethylenediamine, can solve problems such as easy tailing of the chromatographic column and peak bifurcation, failure to meet limit requirements, and high corrosion of the sampling system. Good linear relationship, flat baseline, good dissolution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

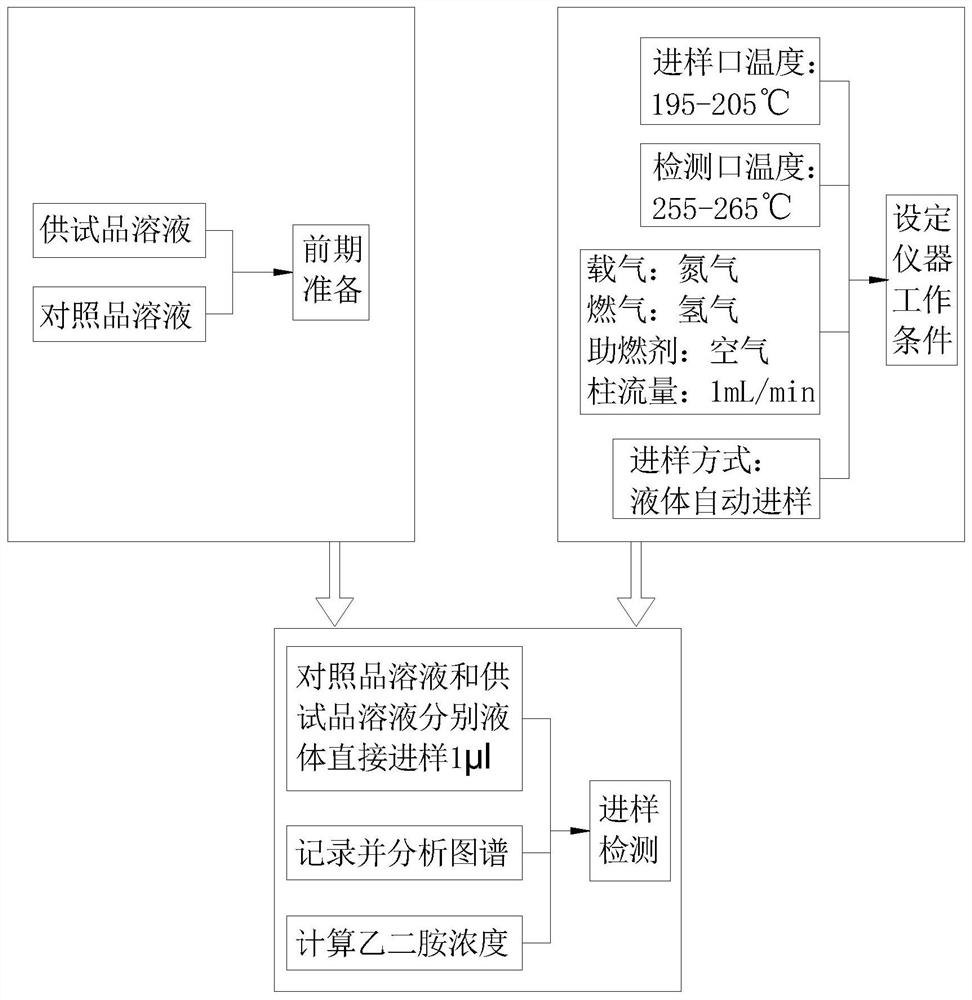

[0038] A gas chromatography detection process for ethylenediamine, such as figure 1 shown, including the following steps:

[0039] Preliminary preparation, measure and dilute the sample as the test solution; measure and dilute ethylenediamine as the reference solution.

[0040] Set the working conditions of the instrument, the temperature of the injection port is 195-205°C (such as 196°C, 200°C, 204°C), the temperature of the detection port is 255-265°C (such as 256°C, 260°C, 264°C), and the carrier gas is Nitrogen gas, hydrogen gas as gas, air as combustion aid, column flow rate as 1mL / min, automatic liquid injection.

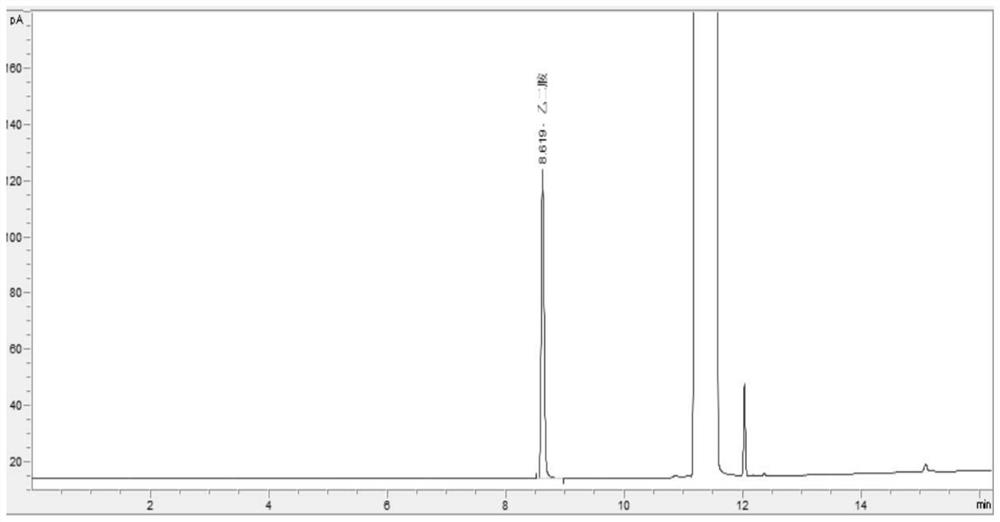

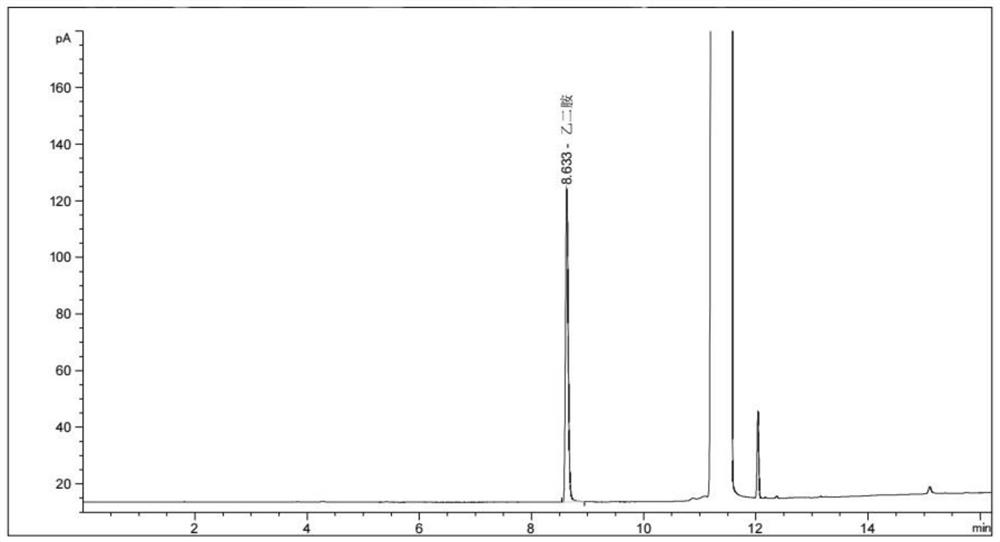

[0041]For sample injection detection, measure 1 μL of the reference solution and 1 μL of the test solution respectively, and then directly inject the liquid into the sample, record and analyze the spectrum, and calculate the concentration of ethylenediamine.

[0042] The working principle of the above-mentioned technical scheme is as follows: when detecting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com