Bolt surface blackening treatment liquid and blackening treatment method thereof

A technology for surface blackening and blackening treatment, applied in the direction of metal material coating process, etc., can solve problems such as environmental pollution, and achieve the effects of avoiding surface strains or cracks, good wear resistance, and reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1 A kind of bolt surface blackening treatment liquid

[0047] Contains the following components:

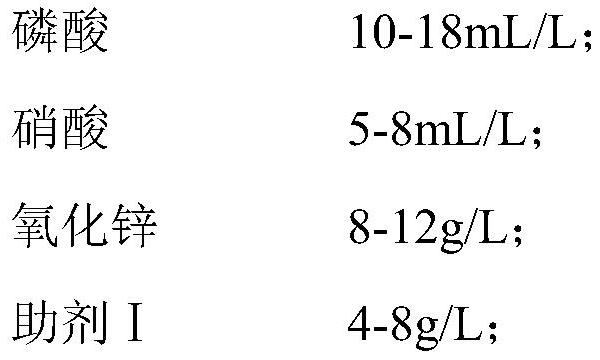

[0048] A component:

[0049]

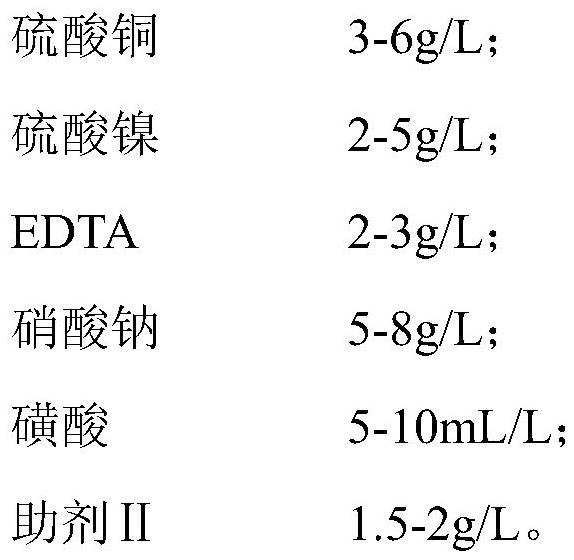

[0050] B component:

[0051]

[0052] The bolt surface blackening treatment process includes the following steps:

[0053] The bolts are cleaned, degreased, washed with water once, derusted, cleaned twice, phosphating / blackened, washed three times, and dried, and the bolts after the blackened treatment are dehydrated and rust-proofed, and the blackened film on the surface is completely dried That is, the blackening process is completed.

[0054] Described degreasing, derusting steps are routine operations in this field;

[0055] Phosphating / blackening treatment: transfer the bolts after secondary cleaning into the blackening tank, now add component A to the blackening tank for phosphating, then add component B for blackening treatment, monitor pH The value is 2.5-3.5, the temperature is 30°C, and the blackening treatment...

Embodiment 2

[0057] Embodiment 2 A kind of bolt surface blackening treatment liquid

[0058] Contains the following components:

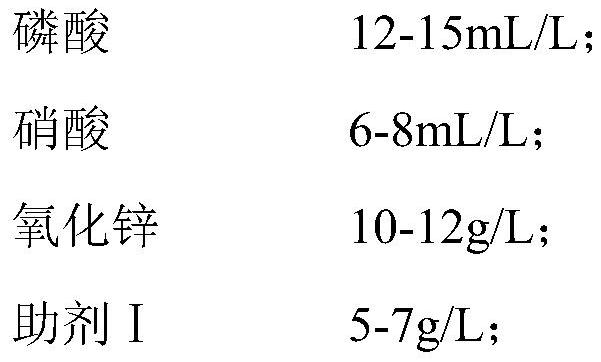

[0059] A component:

[0060]

[0061] B component:

[0062]

[0063] The bolt surface blackening treatment process includes the following steps:

[0064] The bolts are cleaned, degreased, washed with water once, derusted, cleaned twice, phosphating / blackened, washed three times, and dried, and the bolts after the blackened treatment are dehydrated and rust-proofed, and the blackened film on the surface is completely dried That is, the blackening process is completed.

[0065] Described degreasing, derusting steps are routine operations in this field;

[0066] Phosphating / blackening treatment: transfer the bolts after secondary cleaning into the blackening tank, now add component A to the blackening tank for phosphating, then add component B for blackening treatment, monitor pH The value is 2.5-3.5, the temperature is 50°C, and the blackening treatment t...

Embodiment 3

[0068] Embodiment 3 A kind of bolt surface blackening treatment liquid

[0069] Contains the following components:

[0070] A component:

[0071]

[0072] B component:

[0073]

[0074]

[0075] The bolt surface blackening treatment process includes the following steps:

[0076] The bolts are cleaned, degreased, washed with water once, derusted, cleaned twice, phosphating / blackened, washed three times, and dried, and the bolts after the blackened treatment are dehydrated and rust-proofed, and the blackened film on the surface is completely dried That is, the blackening process is completed.

[0077] The steps of degreasing, rust removal, water washing, cleaning and drying are all conventional operations in this field;

[0078] Phosphating / blackening treatment: transfer the bolts after secondary cleaning into the blackening tank, now add component A to the blackening tank for phosphating, then add component B for blackening treatment, monitor pH The value is 2.5-3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com