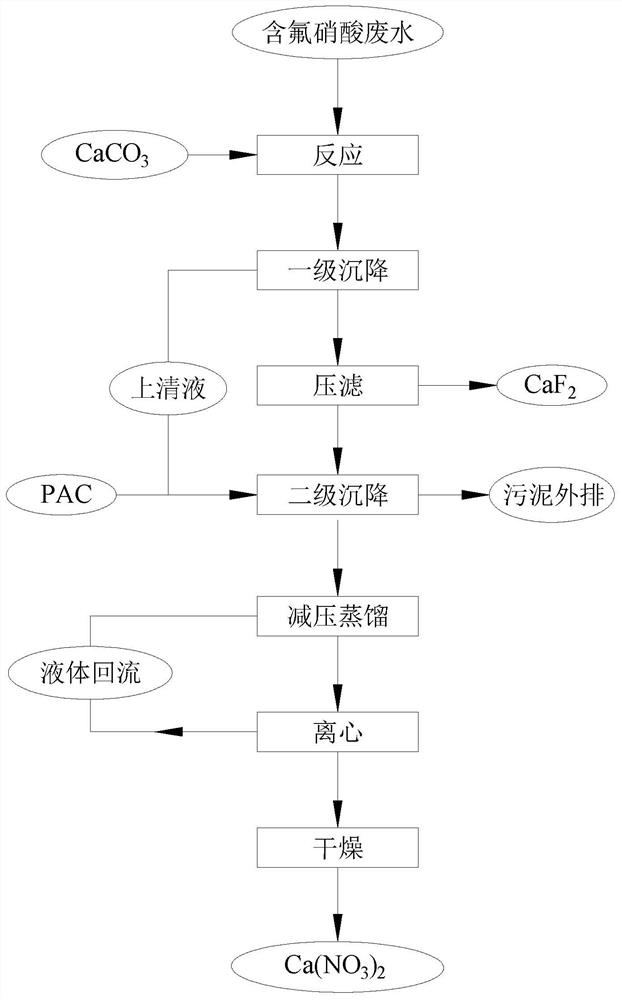

Recovering treatment method of wastewater containing fluorine and nitric acid

A technology for recycling and treating wastewater, applied in multi-stage water treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problem that fluoride ions and nitrate ions cannot be effectively utilized as resources, and achieve low cost and simple process. , the effect of improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

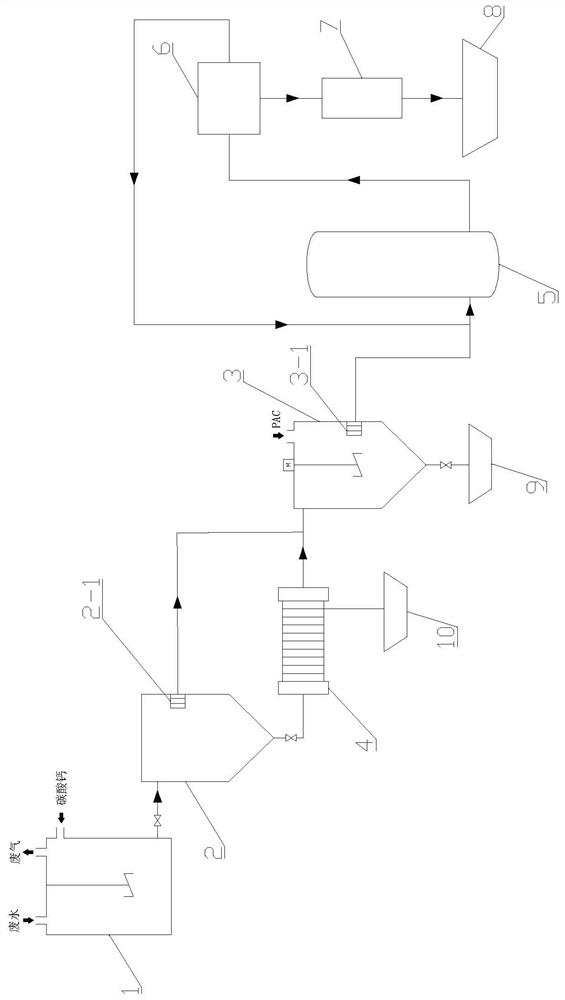

Method used

Image

Examples

Embodiment 1

[0028] Pass 1 ton of waste water containing 1% hydrofluoric acid and 40% nitric acid into the reaction tank, turn on the stirring device, continuously pour heavy calcium carbonate into it, and adjust the solution to neutral. Pass the mixed liquid in the reaction tank into the primary settling tank for 2 hours, and pass the settled sludge into the plate and frame filter press for pressure filtration. The supernatant is filtered through the tertiary filter and passed into the secondary in the settling tank.

[0029] The press-filtered filter cake was taken out, dried at 120° C. for 2 hours, and stored, and the press-filtered filtrate was passed into a secondary settling tank. Add 300g of PAC to the settling tank, after flocculation for 1 hour, filter the supernatant through a filter and pass it into the distillation kettle for vacuum distillation. The pressure of the distillation kettle is -0.03Mpa, the distillation temperature is 90°C, and the distillation time is 30min . The...

Embodiment 2

[0031] Pass 1 ton of waste water containing 3% hydrofluoric acid and 45% nitric acid into the reaction tank, turn on the stirring device, continuously pass heavy calcium carbonate into it, and adjust the solution to neutral. Pass the mixed solution in the reaction tank into the primary settling tank for 3 hours, and pass the settled sludge into the plate and frame filter press for pressure filtration. in the settling tank.

[0032] Take out the filter cake after pressure filtration, dry it at 120°C for 2 hours and store it. The filtrate after pressure filtration is passed into the secondary settling tank, and 400g of PAC is added to the settling tank. After flocculation for 2 hours, the supernatant is passed through the filter screen After filtration, it is passed into a distillation kettle for vacuum distillation. The pressure of the distillation kettle is -0.04Mpa, the distillation temperature is 80°C, and the distillation time is 40min. The sludge in the secondary settling...

Embodiment 3

[0034] Pass 1 ton of waste water containing 5% hydrofluoric acid and 50% nitric acid into the reaction tank, turn on the stirring device, continuously pour heavy calcium carbonate into it, and adjust the solution to neutral. Pass the mixed liquid in the reaction tank into the primary settling tank for 4 hours, and pass the settled sludge into the plate and frame filter press for pressure filtration. The supernatant is filtered through the tertiary filter and passed into the secondary in the settling tank.

[0035] Take out the filter cake after pressure filtration, dry it at 120°C for 2 hours, and store it. The filtrate after pressure filtration is passed into the secondary settling tank, and 500g of PAC is added to the settling tank, and the supernatant is passed through the filter screen after 3 hours of flocculation. After filtration, it is passed into a distillation kettle for vacuum distillation. The pressure of the distillation kettle is -0.05Mpa, the distillation temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com