A kind of skeleton type optical cable and its preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of skeleton type optical cable provided by the invention comprises the following steps:

[0042] Extrusion or coating on the outside of the reinforcement to form the central skeleton;

[0043] Synchronously extruding and prefabricating the surrounding skeleton with the optical fiber, the preferred solution uses a mold to form a longitudinally arranged hollow skeleton groove in the surrounding skeleton and the optical fiber passes through the mould, so that the optical fiber is in the skeleton groove during extrusion and preforming, and a closed prepackage is obtained The surrounding skeleton of the optical fiber is buried; in a preferred solution, solid water-blocking materials such as water-blocking powder are filled in the hollow skeleton groove.

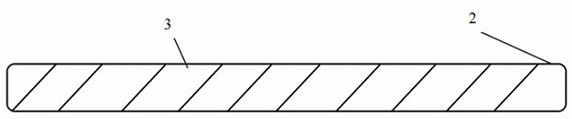

[0044] Wrap the surrounding frame continuously on the central frame in a wrapping manner according to a preset pitch, and extrude a sheath layer around the frame, such as figure 1 As shown, the pitch...

Embodiment 1

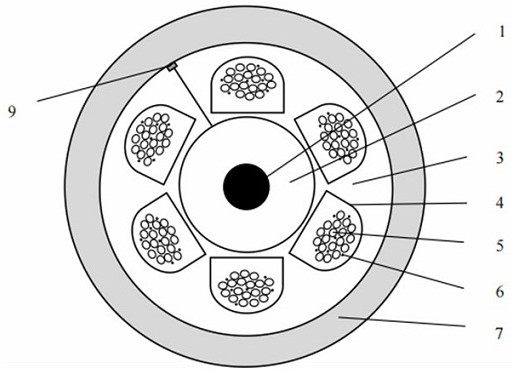

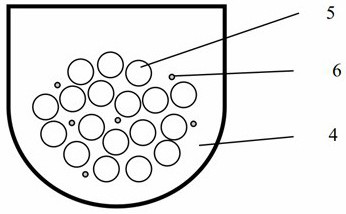

[0048] The skeleton optical cable provided by this embodiment has a structure such as figure 2 As shown, it includes a central frame, a surrounding frame, a central reinforcement, and a sheath layer; the surrounding frame is pre-embedded with optical fibers in a closed manner, and is continuously wrapped on the central frame in a wrapping manner according to a preset pitch; The pitch value of the surrounding skeleton layer wrapping is: 500±100mm;

[0049] The central frame is a circular support frame with an elastic modulus of 1200±50Mpa, which is bonded with high-density polyethylene by polypropylene resin; its outer diameter is 6±3mm, and has a central reinforcement, which is a single Steel wire, steel wire diameter 2.0±0.2mm;

[0050] The surrounding skeleton is a flexible cushioning skeleton, the storage modulus (G') value of the elastomer at room temperature (23°) is 220±10Mpa, and the loss modulus (G'') value is 310±10Mpa; polyester Polyurethane, polyether ether ester...

Embodiment 2

[0060] The skeleton optical cable provided by this embodiment has a structure such as Figure 5 As shown, it includes a central frame, a surrounding frame, a central reinforcement, and a sheath layer; the surrounding frame is pre-embedded with optical fibers in a closed manner, and is continuously wrapped on the central frame in a wrapping manner according to a preset pitch; The pitch value of the surrounding skeleton layer wrapping is: 500±100mm;

[0061] The central frame is a circular support frame with an elastic modulus of 1200±50Mpa, which is bonded with high-density polyethylene by polypropylene resin; its outer diameter is 6±3mm, and has a central reinforcement, which is a single Steel wire, steel wire diameter 2.0±0.2mm;

[0062] The surrounding skeleton is a flexible cushioning skeleton, the storage modulus (G') value of the elastomer at room temperature (23°) is 220±10Mpa, and the loss modulus (G'') value is 310±10Mpa; polyester Polyurethane, polyether ether ester...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

| loss modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com