High-strength and high-conductivity copper-magnesium alloy for dropper, wire rod and preparation method of wire rod

A copper-magnesium alloy, high-strength technology, applied in the field of alloys, can solve problems such as the inability to realize wire production, and achieve the effects of improving thermal processing performance, improving plasticity, and refining grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

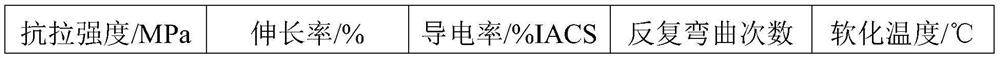

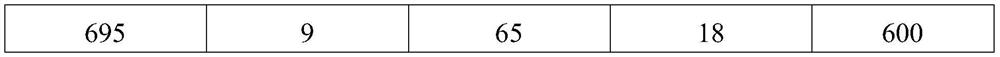

Examples

Embodiment 1

[0025] The Cu-0.5Mg-0.06Cr alloy is prepared, and the raw materials are: A-grade cathode copper, pure magnesium, Cu-5%Cr, and the proportion is according to the weight of the components.

[0026] (1) Upward continuous casting: use non-vacuum power frequency induction furnace for continuous upward casting. Before smelting, add cathode copper and pure magnesium into the non-vacuum power frequency induction furnace. Protected by pure argon, then add Cu-5%Cr intermediate alloy, raise the temperature to 1300°C, after the melt is completely melted, stir evenly, control the casting temperature at 1200°C, and carry out upward continuous casting after holding for 20min. The distance is 3mm, the stop time is 0.24s, the pulling time is 0.06s, the pulling speed is 600mm / min, cast into a copper rod with a diameter of 20mm.

[0027] (2) Continuous extrusion: the above-mentioned alloy copper rod is subjected to multi-pass continuous extrusion on a Conform continuous extrusion machine. The he...

Embodiment 2

[0037]The Cu-0.7Mg-0.02Cr-0.045La alloy is prepared, and the raw materials are: A-level cathode copper, pure magnesium, Cu-5%Cr, and Cu-La master alloy, according to the composition weight ratio.

[0038] (1) Upward continuous casting: use non-vacuum power frequency induction furnace for continuous upward casting. Before smelting, add cathode copper and pure magnesium into the non-vacuum power frequency induction furnace. Pure argon for protection, then add Cu-5%Cr, Cu-La intermediate alloy, raise the temperature to 1250°C, after the melt is completely melted, stir evenly, control the casting temperature at 1150°C, keep it warm for 20min and then carry out the upper lead Continuous casting, the pitch is 1.5mm, the stop time is 0.21s, the pulling time is 0.09s, the pulling speed is 400mm / min, and cast into a copper rod with a diameter of 20mm.

[0039] (2) Continuous extrusion: the above-mentioned alloy copper rod is subjected to multi-pass continuous extrusion on a Conform con...

Embodiment 3

[0049] The Cu-0.6Mg-0.04Cr-0.02Zr alloy is prepared, and the raw materials are: A-grade cathode copper, pure magnesium, Cu-5%Cr, Cu-10%Zr master alloy, according to the composition weight ratio.

[0050] (1) Melting and casting: use a non-vacuum power frequency induction furnace for continuous upward casting. Before smelting, add cathode copper and pure magnesium into the non-vacuum power frequency induction furnace. After the above materials are all melted, feed high-purity Protected by argon, then add Cu-5%Cr intermediate alloy and Cu-10%Zr, raise the temperature to 1280°C, stir evenly after the melt is completely melted, control the casting temperature at 1180°C, keep it warm for 20min and then carry out Lead continuous casting, the pitch is 2mm, the stop time is 0.18s, the pulling time is 0.12s, the drawing speed is 480mm / min, and cast into a copper rod with a diameter of 20mm.

[0051] (2) Continuous extrusion: the above-mentioned alloy copper rod is subjected to multi-pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com