A kind of preparation method of asphalt shingle with superhydrophobic surface

A super-hydrophobic surface, asphalt shingle technology, applied in the direction of roofing, roofing, roof covering and other directions using tile/slate, can solve the problems of easy peeling, long cycle, can not guarantee mechanical durability, etc., to improve the bonding firmness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

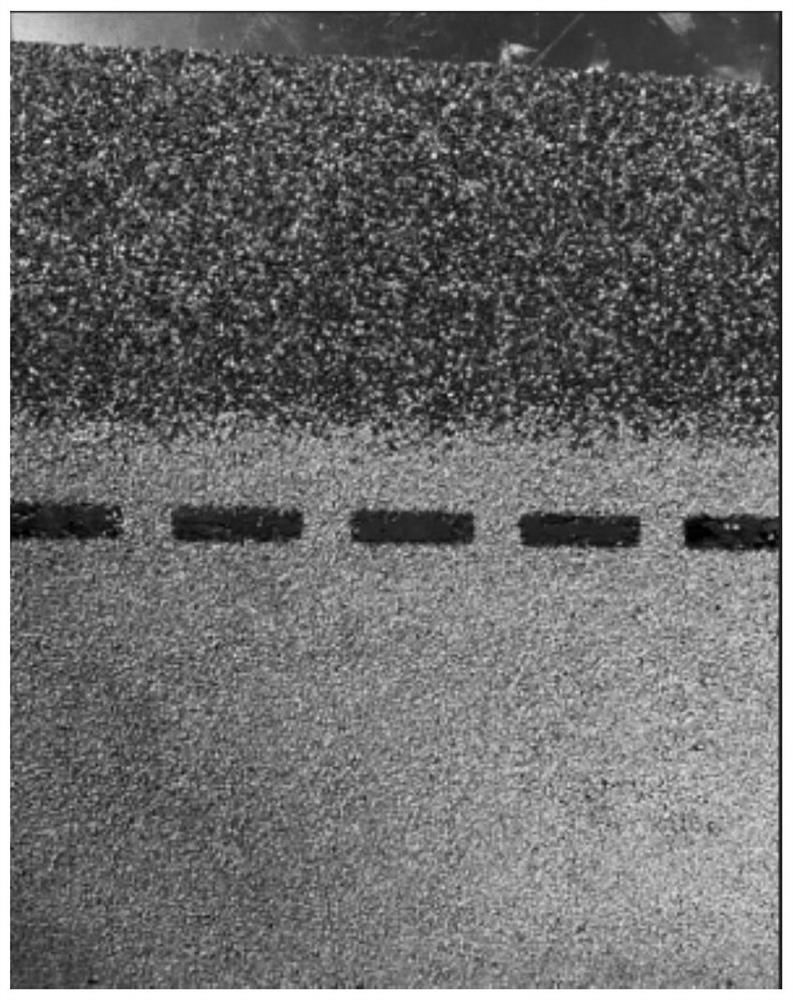

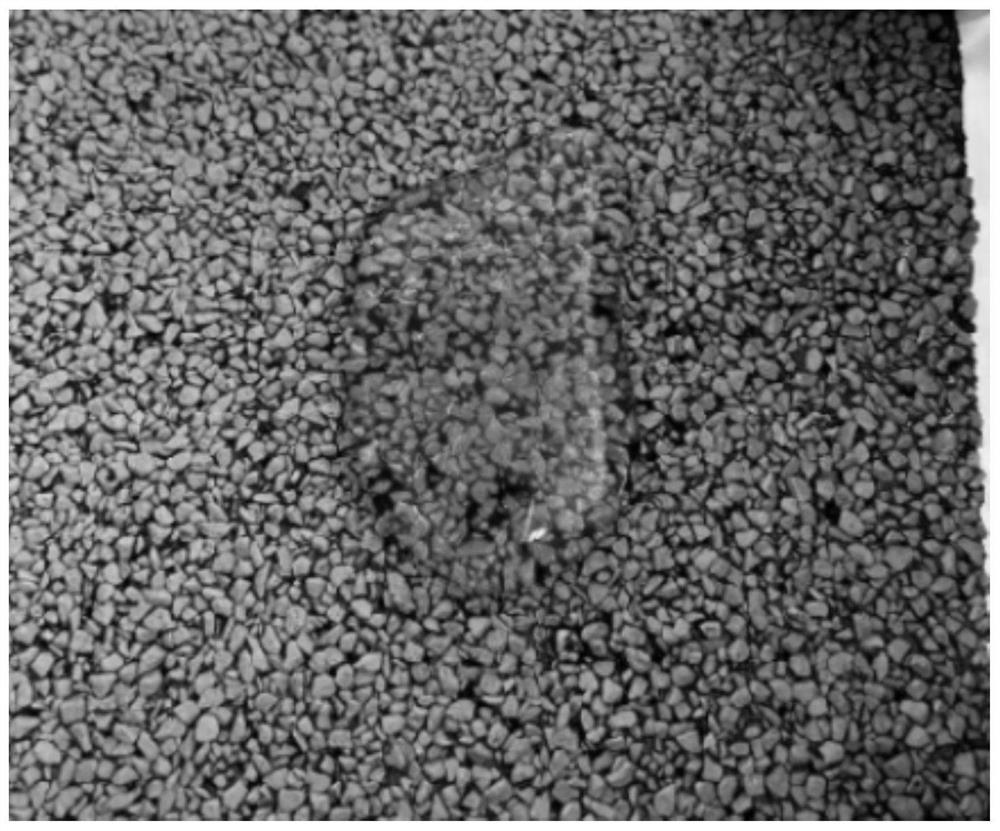

[0034] (1) Use a screening machine to divide the colored sand into fine sand and ultrafine sand. The particle size of fine sand is defined as 1mm and above, and the particle size of ultra-fine sand is defined as below 1mm;

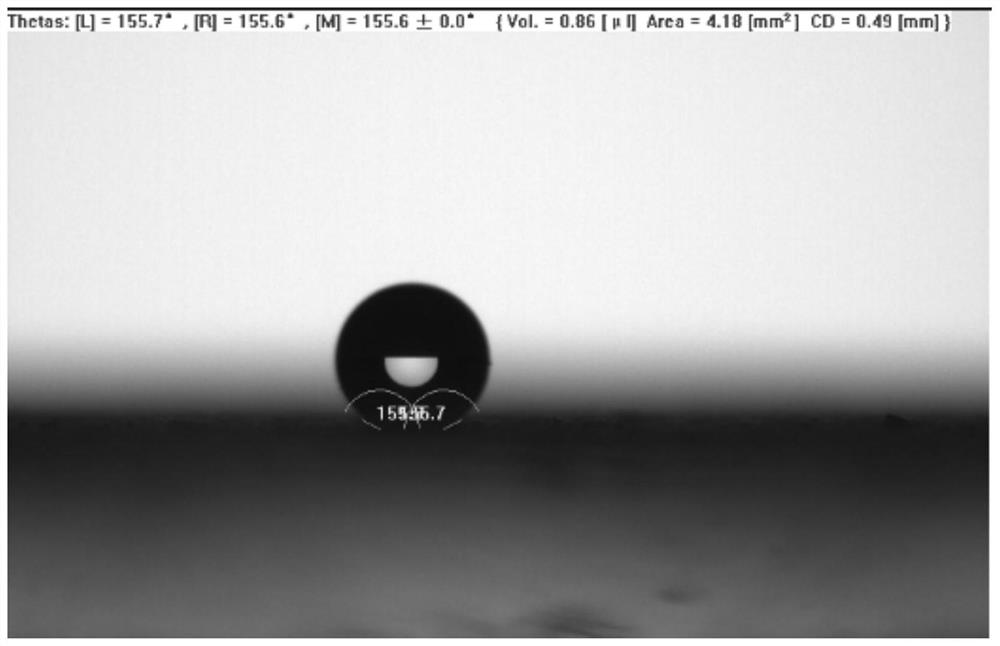

[0035] (2) Mix fine sand and polymethylhydrogen siloxane at a mass ratio of 5:1, and then apply the mixture evenly on the asphalt to be cured, and cure at 120°C for 2 hours to form a pre-cured base. The substrate acts as a first-order rough structure of the superhydrophobic surface;

[0036] (3) Add absolute ethanol to ultrafine sand at a mass ratio of 1:25, stir for 10 minutes with a magnetic stirrer, then add polymethylhydrogen siloxane to absolute ethanol at a mass ratio of 1:25, and stir magnetically Stir for 20 minutes to form a suspension to be sprayed;

[0037] (4) Spray the above-mentioned suspension on the pre-cured asphalt shingle to prepare the secondary rough structure of the super-hydrophobic coating, the pressure of air spraying is 2.0MPa, ...

Embodiment 2

[0039] (1) Use a screening machine to divide the colored sand into fine sand and ultrafine sand. The particle size of fine sand is defined as 1mm and above, and the particle size of ultra-fine sand is defined as below 1mm;

[0040] (2) Mix fine sand and polymethylhydrogen siloxane at a mass ratio of 8:1, and then spread the mixture evenly on the asphalt to be cured, and cure at 125°C for 1.5 hours to form a pre-cured base , the substrate acts as a first-order rough structure of the superhydrophobic surface;

[0041] (3) Add absolute ethanol to ultra-fine sand at a mass ratio of 1:28, stir with a magnetic stirrer for 12 minutes, then add polymethylhydrogen siloxane to absolute ethanol at a mass ratio of 1:28, and stir magnetically Stir with a mixer for 22 minutes to form a suspension to be sprayed;

[0042] (4) Spray the above-mentioned suspension on the pre-cured asphalt shingle to prepare the secondary rough structure of the super-hydrophobic coating, the pressure of air sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com