A preparation method and application of triiron tetroxide@cyclodextrin/carbon nanotube composite that synergistically catalyzes tetrabromobisphenol A in water

A technology of iron tetroxide and carbon nanotubes, applied in chemical instruments and methods, chemical/physical processes, oxidized water/sewage treatment, etc., can solve the problems of excessively long reaction time, poor removal rate, and high removal rate , to achieve the effect of good catalytic performance, preventing agglomeration and high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Treat 25 mg of carbon nanotubes in 20 ml of ethylene glycol solution with an ultrasonic cell disruptor for 30 minutes to disperse the carbon nanotubes evenly.

[0029] (2) Add 0.4g FeCl 3 ·6H 2 O, 1.13g NaAc and 0.4g β-CD were mixed in 10ml ethylene glycol, added to the above mixture, and ultrasonically oscillated for 10 minutes.

[0030] (3) The mixture was transferred to a 50ml polytetrafluoroethylene-sealed autoclave, placed in a vacuum drying oven, heated at 200°C for 8 hours, and cooled to room temperature.

[0031] (4) The separated catalyst was washed with ionized water and absolute ethanol, and finally, the final catalyst was dried in a vacuum oven at 50° C. for 24 hours for use.

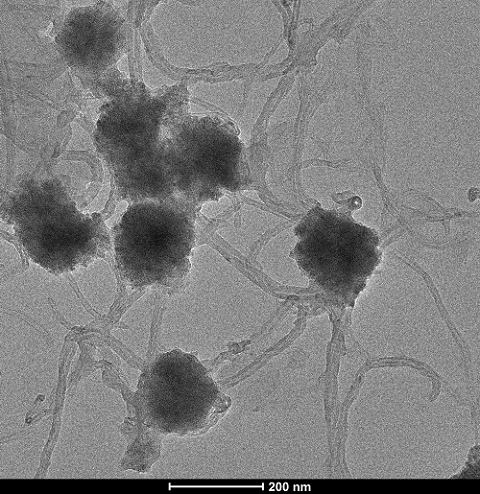

[0032] The prepared Fe3O4 / Carbon Nanotube@Cyclodextrin material was placed under a transmission electron microscope (TEM) to observe the morphology and particle size of the material, and it was found that cyclodextrin modified Fe3O3 particles (200nm) were attached The carbon na...

Embodiment 2

[0034] (1) Treat 25 mg of carbon nanotubes in 20 ml of ethylene glycol solution with an ultrasonic cell disruptor for 30 minutes to disperse the carbon nanotubes evenly.

[0035] (2) Add 0.4g FeCl 3 ·6H 2 O, 1.13g NaAc and 0.4g β-CD were mixed in 10ml ethylene glycol, added to the above mixture, and ultrasonically oscillated for 10 minutes.

[0036] (3) The mixture was transferred to a 50ml polytetrafluoroethylene-sealed autoclave, placed in a vacuum drying oven, heated at 200°C for 8 hours, and cooled to room temperature.

[0037] (4) The separated catalyst was washed with ionized water and absolute ethanol, and finally, the final catalyst was dried in a vacuum oven at 50° C. for 24 hours for use.

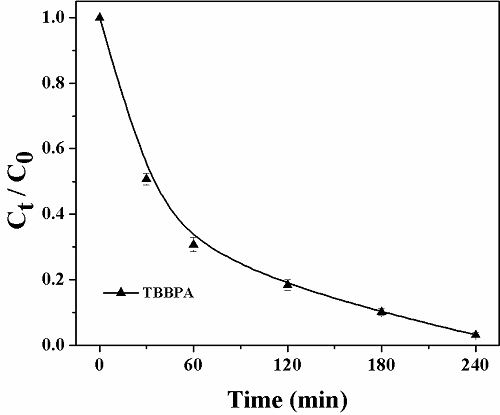

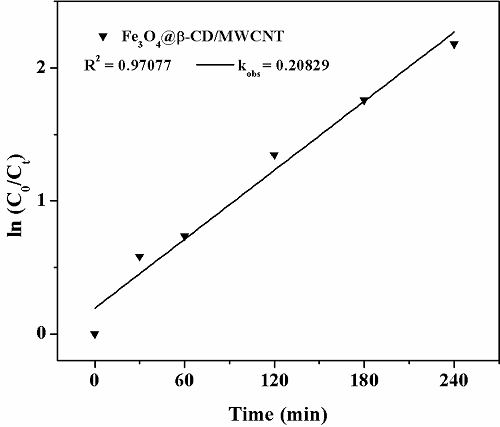

[0038] The prepared material was catalytically degraded with TBBPA as the target pollutant to verify the catalytic performance of the prepared material.

[0039] A known amount of the prepared catalyst was added to a 50 mL Erlenmeyer flask containing 10 mL of a reaction solutio...

Embodiment 3

[0041] (1) Treat 25 mg of carbon nanotubes in 20 ml of ethylene glycol solution with an ultrasonic cell disruptor for 30 minutes to disperse the carbon nanotubes evenly.

[0042] (2) Add 0.4g FeCl 3 ·6H 2 O, 1.13g NaAc and 0.4g β-CD were mixed in 10ml ethylene glycol, added to the above mixture, and ultrasonically oscillated for 10 minutes.

[0043] (3) The mixture was transferred to a 50ml polytetrafluoroethylene-sealed autoclave, placed in a vacuum drying oven, heated at 200°C for 8 hours, and cooled to room temperature.

[0044] (4) The separated catalyst was washed with ionized water and absolute ethanol, and finally, the final catalyst was dried in a vacuum oven at 50° C. for 24 hours for use.

[0045] Carry out magnetic separation to the catalyst that the embodiment 2 carries out catalytic treatment to TBBPA, after collecting, wash with deionized water and ethanol several times, dry and set aside. The optimal experimental conditions were repeated for catalytic degrada...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com